FAST AND EFFECTIVE CLEANING PROCESS

Industrial vacuum cleaners for warehouse maintenance play a key role in maintaining a clean, safe, and productive work environment. Engineered to efficiently capture dust, debris, and solid residues, these machines help minimize health hazards for personnel and lower the risk of workplace accidents. Consistent use of industrial vacuums also supports higher operational efficiency by preventing unplanned downtime and keeping critical areas organized and functional.

Industrial vacuum systems make warehouse cleaning faster and more efficient by combining strong suction performance with high-capacity collection and versatile functionality. These machines are built to handle a wide range of tasks, including:

Overhead surface cleaning

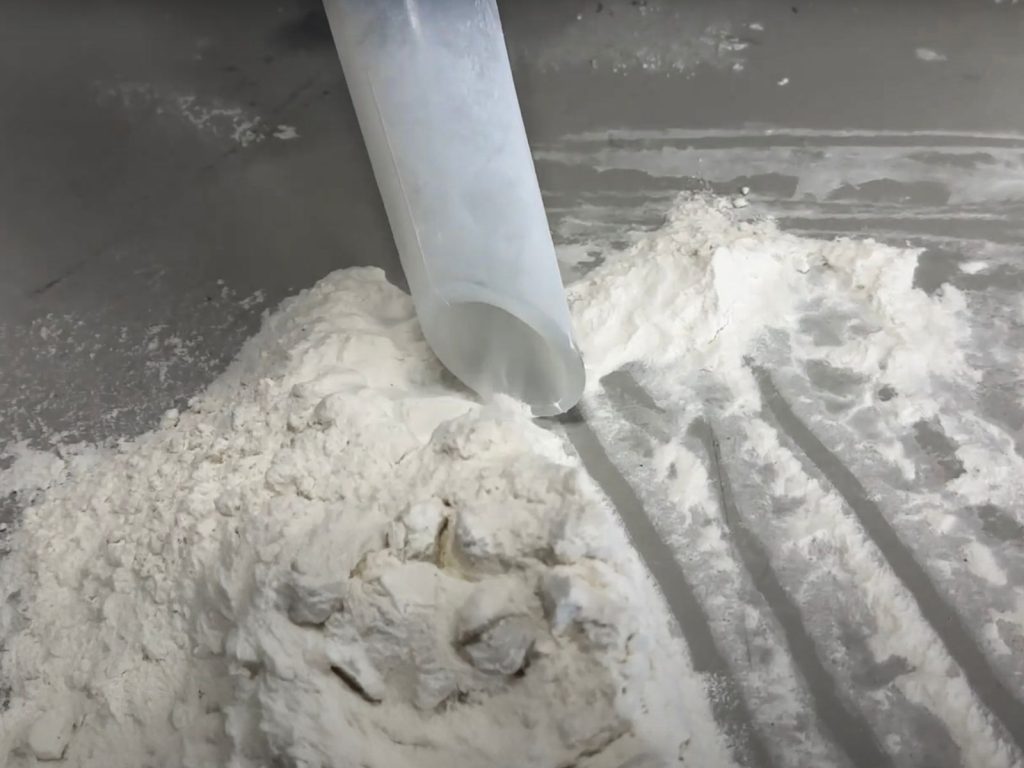

Collection of combustible dust and fine particles

Liquid and sludge recovery

Explore all the available applications and find the right solution for your facility.

Keeping warehouse racking clean is crucial for a safe, organized, and hygienic storage environment. Industrial vacuum systems for logistics include tools designed to clean shelving—even in elevated or tight spaces. With high-reach accessories, operators can easily remove dust and debris from hard-to-access areas. Regular cleaning reduces airborne particles, improves workplace health, and protects stored goods from contamination.

Cleaning air ducts, piping, and overhead structures is key to keeping warehouses safe and free from contaminants. Fine dust tends to build up in elevated areas and can affect air quality if not removed regularly. Industrial vacuum systems with high-reach accessories make it easier to access and clean hard-to-reach spots. Routine maintenance helps control airborne dust, improves safety, and prevents costly unplanned downtime.

Combustible dust from organic or synthetic materials can pose serious hazards in warehouses if not properly controlled. When fine particles accumulate and disperse, they may trigger explosive atmospheres. To reduce risk, it’s crucial to use certified vacuum systems: ACD models in general zones and ATEX-certified units in classified areas. With antistatic filters and grounding, these vacuums provide safe, compliant dust removal.

Liquid spills in warehouses can endanger operator safety and disrupt operations. Water, oil, or chemical leaks must be removed quickly to prevent accidents and protect goods. Industrial wet vacuums allow fast, efficient cleanup, restoring safe working conditions. Their strong suction and capacity help keep floors clear, reduce risks, and improve overall space efficiency and equipment longevity.

Loose labels from packaging or products often end up stuck to warehouse floors, creating clutter or slipping hazards. These sticky residues are hard to remove manually. With the right industrial vacuum and accessories, labels can be quickly lifted from the floor, keeping the workspace cleaner, safer, and more efficient.

Dust tends to build up in hard-to-reach areas like high corners, behind pipes, and under equipment. With powerful suction and the right accessories, industrial vacuums make it easy to clean even hidden or elevated zones. Flexible hoses, slim tools, and high-reach kits help improve air quality and reduce dust-related risks—keeping the warehouse efficient, safe, and well-maintained.

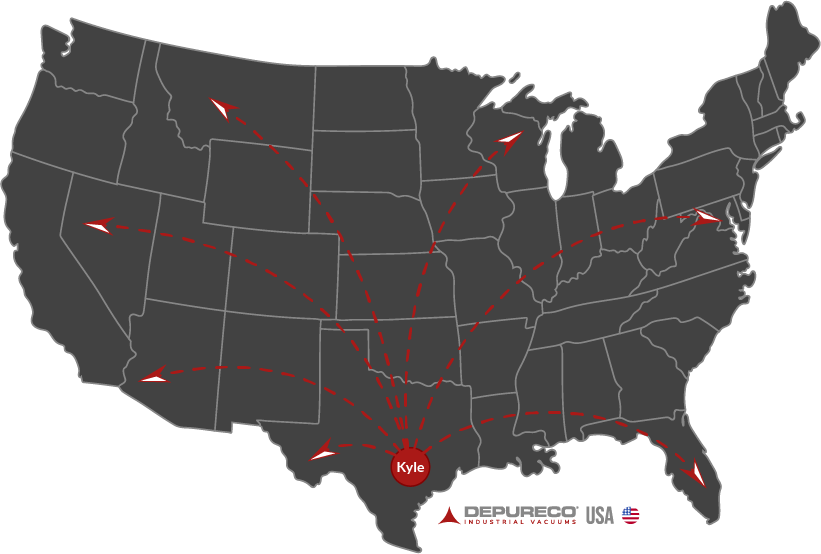

Whatever the challenge—dust, debris, liquids, or explosive risk—Depureco offers the right vacuum solution to keep your warehouse clean, safe, and fully operational. Explore the full range and choose the system that fits your environment best.

Contact us today to learn more about our industrial vacuums for warehouses!

We will give you all the required information