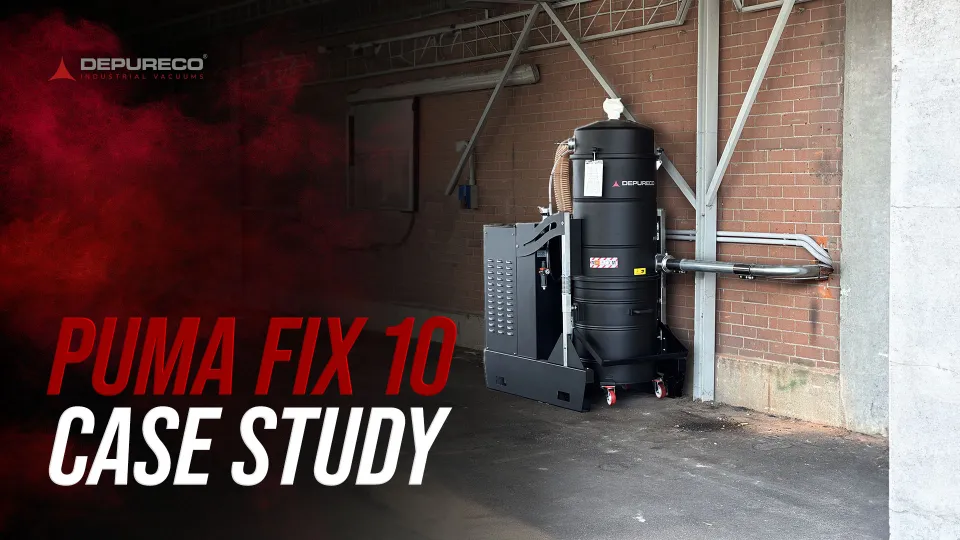

CASE STUDY

Centralized Vacuum System for Welding Fumes in a Metalworking Plant

In any metalworking shop, welding torches generate a continuous stream of welding fumes carrying hazardous particles and gases. These fumes often contain heavy metals and other substances that can cause respiratory problems and long-term health issues if they are not properly extracted.

For a plant with multiple welding stations, relying on a few portable fume extractors or partial ventilation is not enough. Fumes can spread across the production area, exposing workers outside the immediate welding zone and making it harder to meet regulatory limits.

This case study shows how Depureco designed a centralized welding fume extraction system with a PUMA FIX 10 central vacuum unit to improve air quality, protect welders, and keep a metalworking plant compliant and under control.

Customer Profile & Application

The customer is a metalworking industry facility in Italy, with a dedicated welding area and several welding stations operating daily.

The production layout includes:

-

Multiple welding points distributed along a long work area.

-

Welders using torches and magnetic hoods to process medium and large parts.

-

A need to extract fumes directly at the source without limiting mobility.

The plant wanted to move from partial, localized extraction to a single centralized vacuum system capable of collecting welding fumes from multiple stations at once.

The Challenge

Welding Fumes & Air Quality

Welding fumes pose a serious challenge in this type of metalworking environment:

-

Health & safety risks

Welding fumes contain fine metallic particles and gases that can damage the respiratory system and overall health of workers when inhaled over time. -

Regulations & compliance

Exposure limits for welding fumes are increasingly strict. Companies must demonstrate that they control fumes effectively across the entire welding area, not just at one or two stations. -

Multiple welding stations

With several welding points running at the same time, the plant needed an extraction solution that could:-

Capture fumes at source from different positions.

-

Cover the whole welding zone.

-

Operate continuously without performance dropping.

-

-

Air quality across the whole area

Fumes rising and drifting away from the weld can affect not only welders, but also other operators in the same hall. The goal was to improve air quality throughout the welding area, not just at individual heads.

To address these issues, the plant required a centralized welding fume extraction system connected to a single high-performance vacuum unit.

Depureco Solution

Centralized Welding Fume Extraction System

Depureco’s engineering team designed a central vacuum system (CVS) dedicated to welding fumes, built around a PUMA FIX 10 stationary industrial vacuum unit.

The solution combines:

- A central vacuum unit sized for continuous welding fume extraction.

- A network of pipes with multiple suction inlets across the welding area.

- The ability to use several extraction points at the same time.

- Integrated pipe cleaning and an Industry 4.0 control panel for monitoring and control.

This centralized approach lets the plant extract welding fumes from different stations with one system, keeping the entire welding area under control.

System Configuration & Key Features

PUMA FIX 10

Vacuum Unit

Suction Inlet

Control Panel 4.0

Piping Layout & Suction Inlets

The centralized vacuum system for welding fumes includes:

One line installed on each side of the welding area.

More than 300 meters (≈984 feet) of piping in total.

Distributed along both pipelines.

Designed to reach every welding station and cover the entire work area.

The system can support three extraction points at the same time.

Fumes are captured directly at the source using:

- Magnetic hoods positioned near the weld.

- On-torch welding fume extraction where available.

This layout allows welders to work along the full length of the welding area while always having a nearby suction point.

Pipe Cleaning System & Industry 4.0 Control

To keep performance stable and reduce maintenance, the system includes:

Integrated Pipe Cleaning System

- At the end of each operation, an automatic cleaning cycle is activated.

- Strategically positioned shutters open to let air flow through the pipelines, helping remove dust and residues from inside the ducts.

Industry 4.0 Control Panel

- Remote supervision of system status.

- Analysis of usage and performance over time.

- Better planning of maintenance interventions.

Together, these features make the welding fume CVS both efficient and easy to manage as a critical piece of plant infrastructure.

Central Vacuum Unit

PUMA FIX 10

At the heart of the installation is the Depureco PUMA FIX 10, a stationary central vacuum unit developed specifically for centralized vacuum systems.

Key Technical Features

High-Power Side Channel Blower

Approx. 8.7 HP three-phase side channel blower.

Designed for continuous duty in industrial environments.

Provides the vacuum and airflow needed to extract welding fumes from multiple stations.

High-Surface M-Class Filtration

Four large-surface filters with M-class efficiency for fine dust and fumes.

Filtration system designed to handle welding fume particles safely.

Automatic Filter Cleaning (SP System)

SP automatic filter cleaning system uses air counter-blowing to keep filters clean.

Maintains stable suction, reduces manual cleaning, and extends filter life.

Large Collection Capacity

Steel collection bin of approx.

Results & Benefits

Why This Matters

For the Metalworking Plant

By installing the centralized vacuum system for welding fumes, the plant achieved several key benefits:

Improved air quality in the welding area

Welding fumes are extracted directly from multiple stations and removed from the work environment, reducing exposure for welders and nearby staff.Enhanced worker safety

Lower exposure to hazardous fumes supports a safer workplace and helps protect welders’ long-term health.Regulatory compliance support

The system makes it easier to stay within welding fume exposure limits and demonstrate effective control measures during inspections and audits.Efficient multi-station extraction

With up to three suction points in use at the same time, the plant can support several welding operations without compromising extraction performance.Reduced maintenance effort

Automatic pipe cleaning and the SP filter cleaning system keep the system efficient with less manual intervention.Data and monitoring (Industry 4.0)

The 4.0 control panel gives the plant better visibility into system operation, supporting preventive maintenance and data-driven decisions.

Why This Matters

For Metalworking & Fabrication Shops

Many metalworking and fabrication shops face similar challenges:

Multiple welding stations spread across a long work area.

High production volumes and extended welding time.

Increasingly strict exposure limits and safety requirements.

A centralized welding fume extraction system built around a stationary industrial vacuum unit like the PUMA FIX 10 helps:

Capture welding fumes directly at the source across the entire welding area.

Improve indoor air quality and worker comfort.

Simplify compliance with health and safety regulations.

Reduce the number of standalone extractors and simplify maintenance.

Talk to Depureco USA About Welding Fume Extraction

If you run a metalworking shop or fabrication plant with multiple welding stations and need better control of welding fumes, Depureco USA can help.

We design centralized vacuum systems for welding fumes, as well as portable welding fume extractors, tailored to your layout, processes, and safety requirements.

Get in touch with Depureco USA to discuss your welding area and build the right extraction solution for your plant.