CASE STUDY

Vacuum Solutions for Briquetting Presses in CNC Metalworking

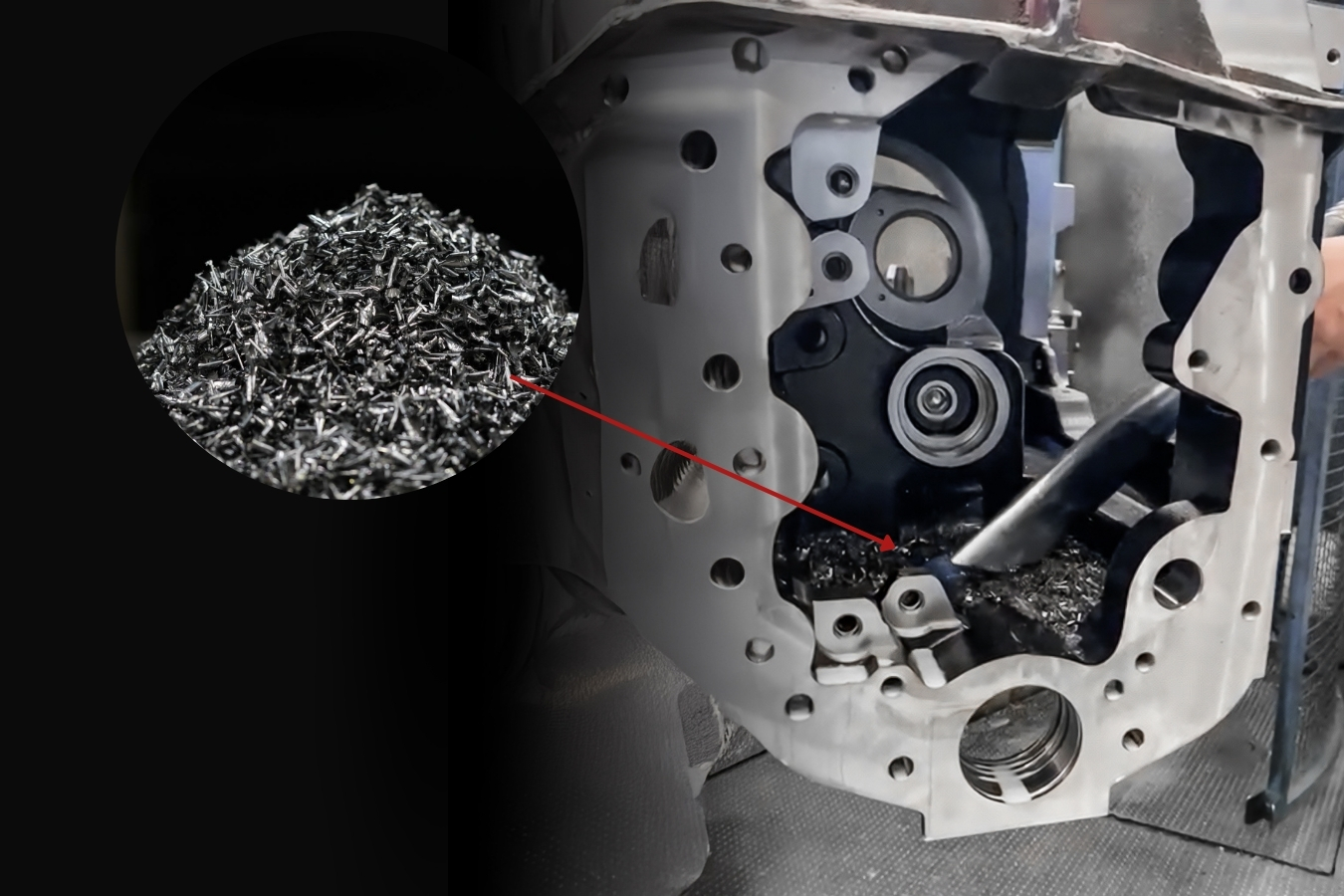

Metal briquetting presses compress loose metal swarf into dense briquettes. This process reduces storage volume, simplifies scrap handling, and improves the melting efficiency of recycling furnaces.

However, many plants still move metal chips manually—using bins, forklifts, or conveyors—from CNC machining centers to the briquetting machine. That means more handling, more housekeeping issues, and more time lost between production and recycling.

In this case study, Depureco helped a leading automotive components manufacturer design a vacuum-based feeding solution for briquetting presses: an HF high-vacuum unit with a fixed chassis that sucks chips directly from CNC machines and discharges them automatically into the briquetting hopper.

Customer Profile & Application

Application: Feeding Metal Briquetting Presses

-

Application: Metal briquetting machine feeding.

-

Location of material: Metal chips are generated inside multiple CNC machining centers.

-

End destination: The chips must be fed into one or more briquetting machines, which compress the swarf into briquettes for recycling.

The Challenge: From Loose Chips to Briquettes

Metal briquetting presses are most efficient when they receive a steady, clean flow of chips, not irregular bin loads. The customer faced several issues:

-

Manual chip handling

Without a vacuum system, operators or forklift drivers had to move bins of metal swarf from each CNC machine to the briquetting press. -

Inefficient operations

-

Time lost moving and dumping containers.

-

Risk of chips spilling on the floor, creating housekeeping and safety problems.

-

-

Storage and floor space

Loose chips take up a lot of room before briquetting. The aim was to reduce storage costs and move material more quickly into briquettes. -

Need for an automatic, closed system

The customer wanted a solution that:-

Collected chips directly inside the CNC machines.

-

Conveyed them automatically through a piping line.

-

Discharged them into the briquetting machine without constant operator intervention.

-

Depureco Solution: HF High-Vacuum Unit with Fixed Chassis

To meet these requirements, Depureco supplied an HF high-vacuum industrial unit with a fixed chassis, configured as a central chip conveying system for the briquetting presses.

The concept is simple:

-

Suck metal chips directly from the CNC machines.

-

Convey them through a pipeline to the HF unit.

-

Use a metal cyclone, filtration, and automatic discharge to feed the briquetting machine hopper.

This turns chip handling from a manual logistics problem into an automatic, vacuum-driven process.

System Configuration & Operating Principle

How the System Works

The HF vacuum solution operates as follows:

-

Vacuum generation

-

Vacuum is generated by a side-channel blower inside the HF unit, providing the negative pressure required to suck chips from CNC machines through the pipeline.

-

-

Material entry & metal cyclone

-

The material enters the vacuum system at the inlet.

-

It immediately passes through a metal cyclone, where the airflow changes direction.

-

This causes the chips to lose speed and fall into the collection hopper, separating them from the air stream.

-

-

Filter protection for the blower

-

A dedicated filter element protects the blower from any fine particles that might be carried upwards.

-

The filter ensures that no material returns towards the turbine, preserving the blower and maintaining performance.

-

-

Automatic discharge to the briquetting machine

-

Once collected, the chips are automatically discharged into the briquetting machine hopper.

-

The system can be configured with different discharge options, depending on how the press and hopper are arranged (for example, discharge valves, chutes, or other mechanical solutions).

-

By combining a high-vacuum HF unit, cyclone separation, and automatic discharge, the system offers a continuous, controlled feeding of metal chips to the briquetting presses.

HF Vacuum Unit with Fixed Chassis: Key Features

The HF unit used in this project is installed on a fixed chassis, designed as a dedicated feeding station for the briquetting presses.

High-Vacuum Performance

-

Side-channel blower for strong, continuous vacuum.

-

Designed to handle dense, heavy metal chips and long piping runs from CNC machines to the briquetting area.

Cyclonic Pre-Separation & Filtration

-

Metal cyclone at the inlet:

-

Reduces the speed of incoming material.

-

Forces chips to drop into the hopper, minimizing direct impact on the filter.

-

-

Protective filter:

-

Shields the blower from any remaining fines that might travel with the air.

-

Helps maintain stable performance and reduce maintenance.

-

Automatic Discharge Options

-

Automatic discharge system from the HF hopper to the briquetting machine:

-

Enables continuous or batch feeding, depending on briquetting press cycle.

-

Multiple discharge configurations are available to adapt to different hopper heights and layouts.

-

This configuration turns the HF into a reliable, high-vacuum transfer station between CNC machining and briquetting.

Results & Benefits for the Automotive Components Manufacturer

By implementing the HF vacuum solution for briquetting presses, the customer achieved several concrete benefits:

-

Direct chip collection from CNC machines

Chips are no longer left in machines or collected manually; they are vacuumed directly inside the CNC equipment and sent toward the briquetting area. -

Automatic feeding of the briquetting press

The briquetting machine receives a steady, automatic flow of swarf, improving press utilization and making briquetting more continuous. -

Reduced storage and handling costs

-

Faster transfer from loose chips to dense briquettes.

-

Fewer intermediate containers and less floor space dedicated to loose scrap.

-

-

Cleaner, safer production environment

Less swarf on the floor and around machines means a safer, more organized shop and fewer housekeeping interventions. -

More efficient metal recycling

Dense briquettes improve the conversion ratio in the furnace for metal recycling, increasing value recovery from scrap.

Why This Matters for CNC Shops Using Briquetting Presses

For CNC machining shops—especially in sectors like automotive, heavy equipment, or general metalworking—metal swarf is both a waste stream and a resource.

If chips are handled manually, piled in bins, and only occasionally moved to the briquetting press, you lose time, space, and operational efficiency.

A vacuum solution for briquetting presses, based on a high-vacuum HF unit with a fixed chassis, helps you:

-

Simplify chip logistics between machines and the press.

-

Keep aisles and machine areas cleaner.

-

Increase briquetting throughput and the value of recycled metal.

-

Reduce the number of manual operations needed to move and dump chips.

Talk to Depureco USA About Briquetting Feed Solutions

If you’re running CNC machining operations and using briquetting presses to compact metal swarf, Depureco USA can help you design a vacuum-based feeding system tailored to your layout and production volume.

We engineer high-vacuum solutions with HF units, cyclonic separation, and automatic discharge options to move chips directly from machines to briquetting, keeping your recycling loop efficient and under control.

Get in touch with Depureco USA to discuss your chip management and briquetting application.