CASE STUDY

Central Vacuum System for Dry Metal Chips on Tractor Gearbox Blocks

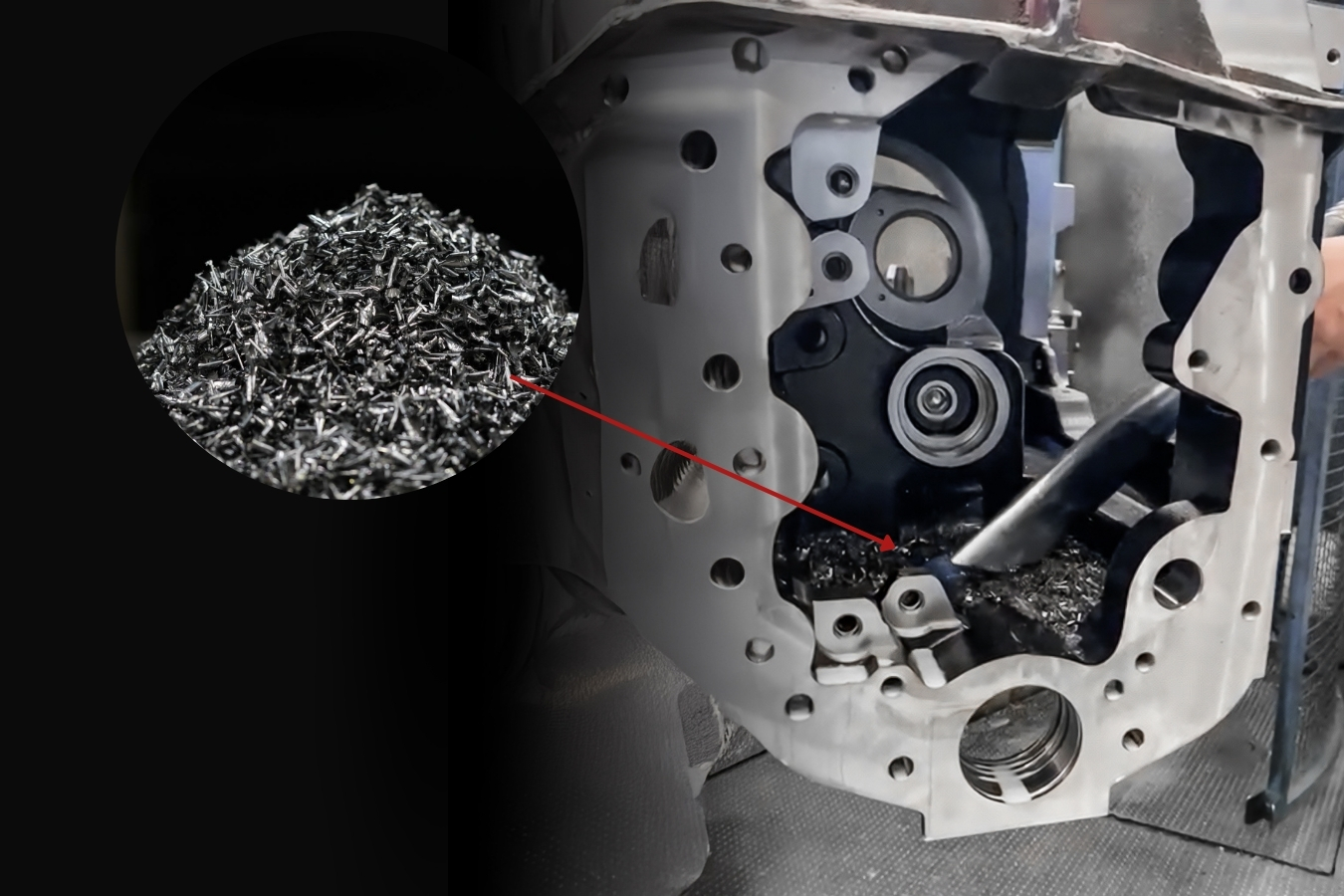

During CNC machining, dry metal chips build up on parts, fixtures, and inside the machine. On precision components like tractor gearbox blocks, any leftover swarf can damage sensitive surfaces, clog coolant channels, and compromise assembly.

Relying on air blow guns or manual brushing is slow, inconsistent, and pushes chips into hard-to-reach areas instead of removing them. The result is more rework, more cleaning, and more downtime.

In this case study, Depureco implemented a central vacuum solution for dry metal chips using four HF 300 stationary industrial vacuums, each integrated with a CNC machine. The system removes chips quickly and discharges them automatically into the CNC collection system, keeping components and machines clean with minimal operator effort.

Customer Profile & Application

The customer is a major tractor manufacturer, producing transmission and drivetrain components for agricultural machinery.

Application: Cleaning Dry Metal Chips from Gearbox Blocks

Components: Steel or cast-iron gearbox blocks for tractor transmissions.

Process: Machining on CNC machines.

Material to collect: Fine, dry metal chips and swarf remaining on the surface and in pockets after machining.

Before the next assembly stages, each gearbox block must be thoroughly cleaned to remove all residual chips and protect the most delicate internal components.

The Challenge: Managing Dry Metal Chips After CNC Machining

The manufacturer faced several critical issues tied to dry metal chips:

Preventing damage to sensitive surfaces

Residual chips on finished gearbox blocks could damage bearing seats, sealing surfaces, and precision-machined areas.Avoiding blockages and malfunctions

Chip buildup risked clogging fixtures, coolant channels, and internal pockets, leading to malfunctions or non-conforming parts.Maintaining production continuity

Slow or inefficient cleaning steps extended cycle times and increased the risk of unplanned downtime between machining and assembly.Reducing manual handling and rework

Manual cleaning with air blow guns or brushes was labor-intensive, inconsistent, and often pushed chips deeper into the part instead of removing them.

The plant needed a fast, repeatable cleaning process that could:

Remove dry metal chips directly at the machine.

Protect high-precision surfaces.

- Keep overall production flow continuous.

DEPURECO SOLUTION

Depureco Solution: Four HF 300 Stationary Vacuums for Dry Chips

HF 300

Gearbox Block

Vacuuming Dry Metal Chips

To address this need, Depureco engineered a dedicated chip-cleaning solution integrated with every CNC machine.

The system is based on:

Four HF 300 stationary industrial vacuums

One HF 300 unit per CNC machine.

- <p”>Each installed as a fixed, local central vacuum for that machine.

On-board chip extraction

Dry metal chips are vacuumed directly from the gearbox blocks and surrounding areas.

Collected material is discharged automatically into each CNC’s existing collection system.

This configuration allows operators to clean each gearbox block in a short, controlled cycle and send chips straight into the CNC discharge, simplifying operations and reducing downtime.

System Configuration & Operating Principle

Cleaning Process on the CNC Machines

For each CNC machine:

- After machining, the operator activates the HF 300 vacuum.

Dry metal chips are vacuumed from the entire surface of the gearbox block and from pockets and corners around the work area.

- The HF 300 collects chips inside its body during suction.

When suction stops, the discharge system automatically releases chips into the CNC’s collection system.

Each HF 300 is designed to clean the entire surface of a gearbox block in less than two minutes, minimizing idle time between machining and assembly.

Counterbalanced Flap Discharge System

A key feature of the installation is the counterbalanced flap discharge system:

During suction, the flap remains closed, allowing chips to accumulate in the HF 300.

When suction stops, the flap opens automatically.

Collected chips fall directly into the CNC machine’s collection hopper or conveyor.

- Eliminates manual chip handling (no more scooping or emptying containers).

- Reduces downtime, as chips are discharged automatically at the right point in the cleaning cycle.

- Allows the system to operate continuously and without interruption, even with significant chip volumes.

Vacuum Unit: HF 300 Stationary Industrial Vacuum

The vacuum unit selected for this application is the Depureco HF 300, a three-phase stationary system specifically designed for dry metal chips and swarf.

High-Performance Side Channel Blower

Approx. 4.8 HP (≈3 kW) three-phase side channel blower.

Provides strong, continuous suction even over several meters of piping.

M-Class Polyester Star Filter

M-class star filter with filtration efficiency down to 1 micron.

Protects the blower from fine dust and ensures clean exhaust air.

Large Filter Surface

Approx. 24,000 cm² / 3,720 in² filter area.

The large surface area keeps pressure drop low and maintains consistent suction.

Manual Filter Shaker

Practical, manual filter shaker for quick, tool-free cleaning.

Helps maintain high performance and reduce filter maintenance.

Tangential Inlet With Cyclone Effect

The tangential inlet directs air and chips to create a cyclone effect.

Heavier particles are forced to drop before reaching the filter, extending filter life and system stability.

Stationary, Heavy-Duty Construction

Fixed structure designed for continuous service next to CNC machines.

Built to support intensive, multi-shift industrial operations without clogging or loss of suction.

The HF 300 is optimized for fine, dry metal chips and can handle continuous duty without clogging or losing suction power.

Key Technical Features

Side Channel Blower

M-Class Star Filter

Tangental Inlet

Results & Benefits

For the Tractor Manufacturer

By installing four HF 300 stationary industrial vacuums, one on each CNC machine, the manufacturer achieved:

Faster, more consistent cleaning cycles

Each gearbox block can be cleaned in less than two minutes, keeping the cleaning step aligned with production cycle times.Protection of critical surfaces

Thorough chip removal prevents damage to bearing seats, sealing areas, and other precision-machined features, improving part quality.Fewer blockages and machine issues

Removing chips at the source reduces blockages in fixtures and coolant channels, supporting stable machining conditions.Reduced manual handling and operator fatigue

Automatic discharge via the counterbalanced flap system removes the need for manual chip handling, limiting operator effort and risk.Continuous, reliable suction performance

The HF 300 units maintain stable performance even with fine, dry chips and intensive use, supporting continuous production.Cleaner, safer work environment

Work areas around the CNC machines stay cleaner, with less loose swarf on tables, fixtures, and floors.

Why This Matters for CNC Machining & Tractor Manufacturing

For tractor manufacturers and other heavy equipment builders, gearbox blocks and transmission components are critical parts with tight tolerances.

Uncontrolled dry metal chips can:

Damage machined surfaces and lead to scrap or rework.

Clog internal passages and create failures later in the field.

Extend cleaning times and interrupt production flow.

A central vacuum system for dry metal chips, built around stationary vacuums like the HF 300, helps:

Standardize the cleaning process across multiple CNC machines.

Protect high-precision parts before assembly.

Reduce downtime, rework, and manual cleaning.

Improve overall productivity and component quality.

Talk to Depureco USA About Dry Metal Chip Solutions

If you need to remove dry metal chips from CNC-machined parts—especially high-value components like gearbox blocks—Depureco USA can help.

We design:

Stationary chip collection systems with HF 300 units.

Integrated discharge solutions for CNC collection systems and conveyors.

Custom configurations for steel, cast iron, aluminum, and mixed-metal swarf.

Get in touch with Depureco USA to discuss your machining application and build a central vacuum system for dry metal chips tailored to your production line.

FAQ's

What metals can the HF 300 collect?

It efficiently handles fine, dry chips from steel, cast iron, aluminum, copper, brass, and stainless steel machining.

How long does it take to clean each gearbox block?

Less than two minutes per part, with four CNC machines operating simultaneously.

Does the vacuum operate continuously?

Yes. The HF 300 runs in continuous duty with automatic discharge to avoid interruptions.

How does the discharge system work?

When suction stops, the counterbalanced flap opens, releasing chips directly into the CNC’s collection system—no manual emptying required.

What filtration system is used?

An M-Class polyester star filter with 1 µm efficiency protects the blower and ensures long-term performance with a manual shaker for easy cleaning.