SAFETY DEALING WITH COMBUSTIBLE DUST

NFPA compliant industrial vacuum cleaners designed specifically for the food industry, offering powerful suction and specialized filtration to effectively and safely handle combustible dust particles. Ensure a safe and hygienic working environment while minimizing the risk of dust explosions with these essential cleaning solutions.

The food industry is a dynamic and complex sector that demands strict adherence to safety standards, GMP and regulations. One significant challenge faced by food manufacturers and processors is the presence of combustible dust, which can pose a serious threat to both employee safety and facility integrity. To address this issue effectively, utilizing industrial vacuum solutions becomes essential. However, it is crucial to ensure that the industrial vacuum cleaners used in these settings comply with the National Fire Protection Association (NFPA) standards to maintain a safe working environment. In fact, the new NFPA 660 is a new standard for combustible dust that the NFPA is developing to consolidate several existing standards into a “one-stop-shop” for combustible dust regulations, making it easier for industries dealing with combustible dust to understand and comply with the standards, minimizing risks for workers and companies.

Mobile vacuums with excellent filtration capacity, designed to effectively capture and contain fine dust, which can pose a significant health hazard to workers and even damage machinery.

Combustible dust can pose a serious threat to both employee safety and facility integrity. To address this issue effectively, utilizing industrial vacuum solutions becomes essential. However, it is crucial to ensure that the industrial vacuum cleaners used in these settings comply with the National Fire Protection Association (NFPA) standards to maintain a safe working environment.

Dust collectors play a vital role in the food industry by effectively capturing and controlling airborne particles, ensuring a clean and safe working environment. By utilizing dust collectors, food manufacturers can maintain product quality, improve equipment longevity, and adhere to strict hygiene standards and regulations such as GMP and NFPA ones.

Efficient collection of scraps on board of machinery is essential in the food industry to prevent cross-contamination, maintain hygiene standards, and optimize production processes. By implementing effective scrap collection systems, food manufacturers can minimize waste, enhance operational efficiency, and ensure the smooth functioning of their machinery.

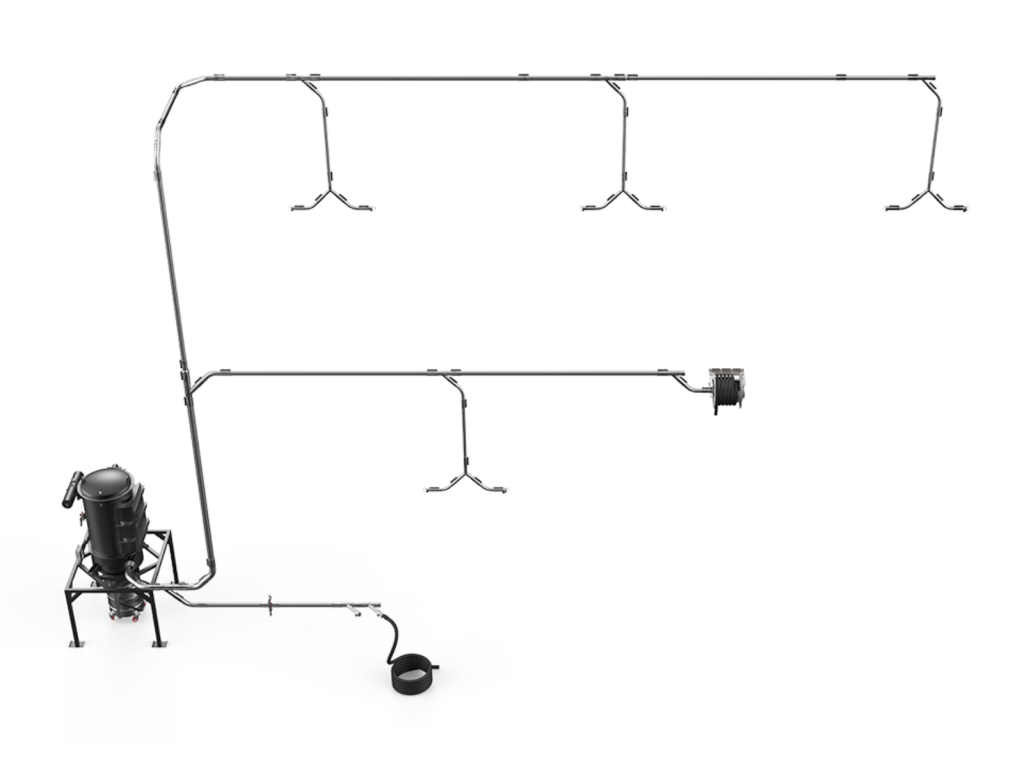

Central vacuum system features superior cleaning quickness, efficiency, reduced cross-contamination risk, quieter operation, and long-term cost-effectiveness compared to mobile vacuum solutions, making it an essential and advantageous choice in the food industry.

Ensure a safe and compliant work environment, mitigate the risks of combustible dust, and optimize cleaning processes.

Our expertise in NFPA compliant industrial vacuum cleaners will help you maintain high standards of cleanliness, enhance employee safety, and uphold regulatory requirements, ultimately contributing to the success and reputation of your food industry operations.

Contact us for a free on-site assessment