2 kW | 2.7 HP

34 gal

The WD 132 P offers an optimal suction solution for effortlessly and securely collecting various types of substances, including dust, solids, liquids, and light sludge. Its industrial suction power is achieved through the collaboration of two By-Pass motors, which work in parallel to enable swift liquid collection. To facilitate the entry of vacuumed materials, the device features a metal inlet with an internal die-cast deflector made of aluminum alloy and cast iron. This deflector effectively guides the material towards the container’s bottom, preventing it from reaching the filter. As a result, the filter remains protected, ensuring an extended lifespan.

Constructed with a 34 gal container capacity, the WD 132 P vacuum cleaner is crafted from painted steel, although it can be optionally provided in AISI 304 stainless steel. For convenient discharge, the device employs a manual ball valve located at the container’s bottom, allowing gravity to facilitate the process. Moreover, the vacuum cleaner incorporates both an external level indicator to monitor the amount of liquid vacuumed and an internal level indicator that automatically stops the suction once the maximum capacity is reached.

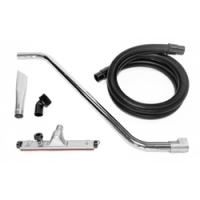

The WD 132 P industrial vacuum cleaner comes equipped with two separate filter kits, one designed for capturing dust and the other for handling liquids. This feature ensures the vacuum cleaner’s safe utilization across diverse applications. Additionally, the vacuum cleaner includes the Wet&Dry suction kit as a standard component.

The suction power of the vacuum is produced by two separate by-pass motors. Each motor can be controlled individually using an independent switch, allowing the operator to regulate the intake performance according to their needs. These motors are housed within a robust casing, which is equipped with an insulating sponge to effectively minimize noise levels.

The vacuum cleaners in the WD range are designed for the effective vacuuming and separation of liquids or dust. There are two filter options available: a polypropylene filter for filtering and separating any solid materials that may be present in the vacuumed liquids, and a polyester filter specifically designed for dust vacuuming. Both filters are washable, providing convenience and reusability.

The discharge process occurs naturally through the force of gravity. Positioned at the bottom of the machine, there is a valve that facilitates the effortless removal of the liquids and particles that have been accumulated inside the bin.

As an additional feature, it is feasible to install an electric submersible pump within the bin, allowing for the convenient discharge of liquids even when using a short length of flexible hose. With the inclusion of a non-return valve, both the vacuuming and discharging processes can be performed simultaneously, eliminating the need to halt the machine.