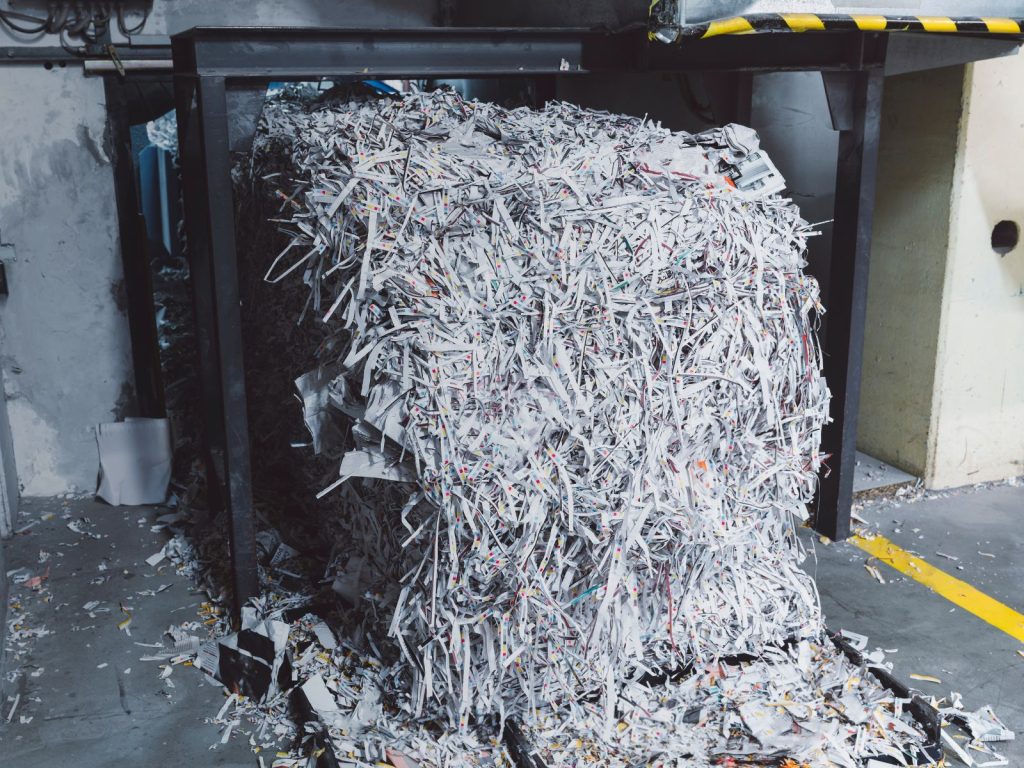

Are you dealing with light trims, cotton, fabric scraps, plastic film trims, or paper waste in your production process?

These lightweight materials present a unique challenge to standard vacuum systems. Without the right equipment, these scraps can quickly clog filters, reducing efficiency and increasing downtime.

Thanks to our industrial vacuum solutions for light trims and flying materials, you can:

In standard vacuum cleaners, the airflow typically moves from bottom to top. While this design works for heavier debris, it’s problematic for light trims. These lightweight materials, like fabric scraps or plastic film, get carried directly to the filter by the upward airflow. Due to their large surface area and tendency to develop static charges, they easily cling to the filter material instead of falling away. Standard filters aren’t designed to shed these materials effectively, and most vacuums lack pre-separation systems to capture them before reaching the main filter.

As a result, light trims quickly accumulate on the filter surface, creating a barrier that restricts airflow and rapidly decreases suction power. This unique combination of factors is why standard vacuums struggle with light trims, leading to frequent clogging and reduced efficiency.

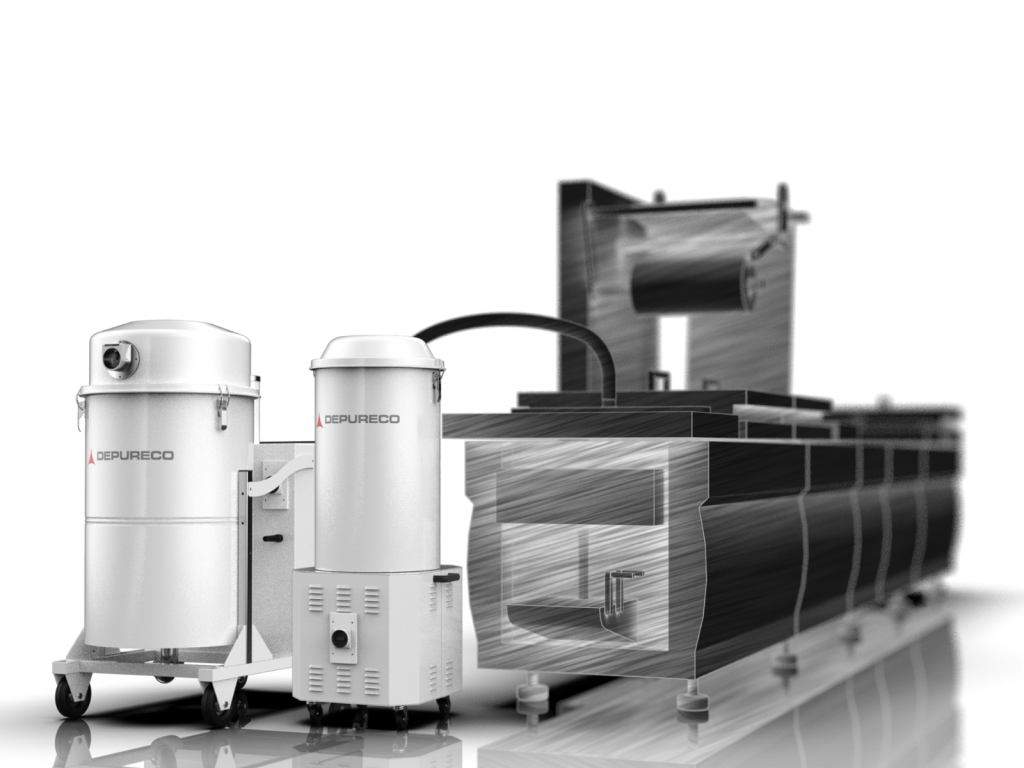

Our trims interceptor is a separator designed specifically to tackle the challenges of light trims and flying materials. By intercepting these troublesome particles before they reach the main vacuum system, it significantly reduces filter clogging and maintains optimal suction power.

How does it work? The trims interceptor uses a smart pre-separation system to capture light materials from the airstream. As debris enters the unit, it’s directed into a large collection container, where the air velocity decreases, allowing the light trims to settle.

This design effectively traps the majority of light materials, while allowing only the cleanest air to pass through to the main vacuum. This process not only extends filter life but also improves overall system efficiency, reducing downtime and maintenance costs. Integrating the trims interceptor into your existing setup is simple, and the benefits are immediate!

AS and AS 400 are vacuum cleaners designed for handling scraps and large cuttings from production processes in packaging, textiles, and beyond. They feature a high-capacity collection chamber and innovative bottom suction, ensuring vacuumed materials are sent directly into a filter bag. This design excels at collecting light materials like paper, plastic, and packaging trimmings. Powered by a side-channel blower positioned beneath the collection chamber, the AS and AS 400 provide exceptional suction power. An inspection window on the top cover allows operators to monitor material levels without interrupting operation. As part of our food & pharma range, the AS and AS 400 are versatile enough for various industries where cleanliness and efficient waste management are crucial.