Industry: Chemical

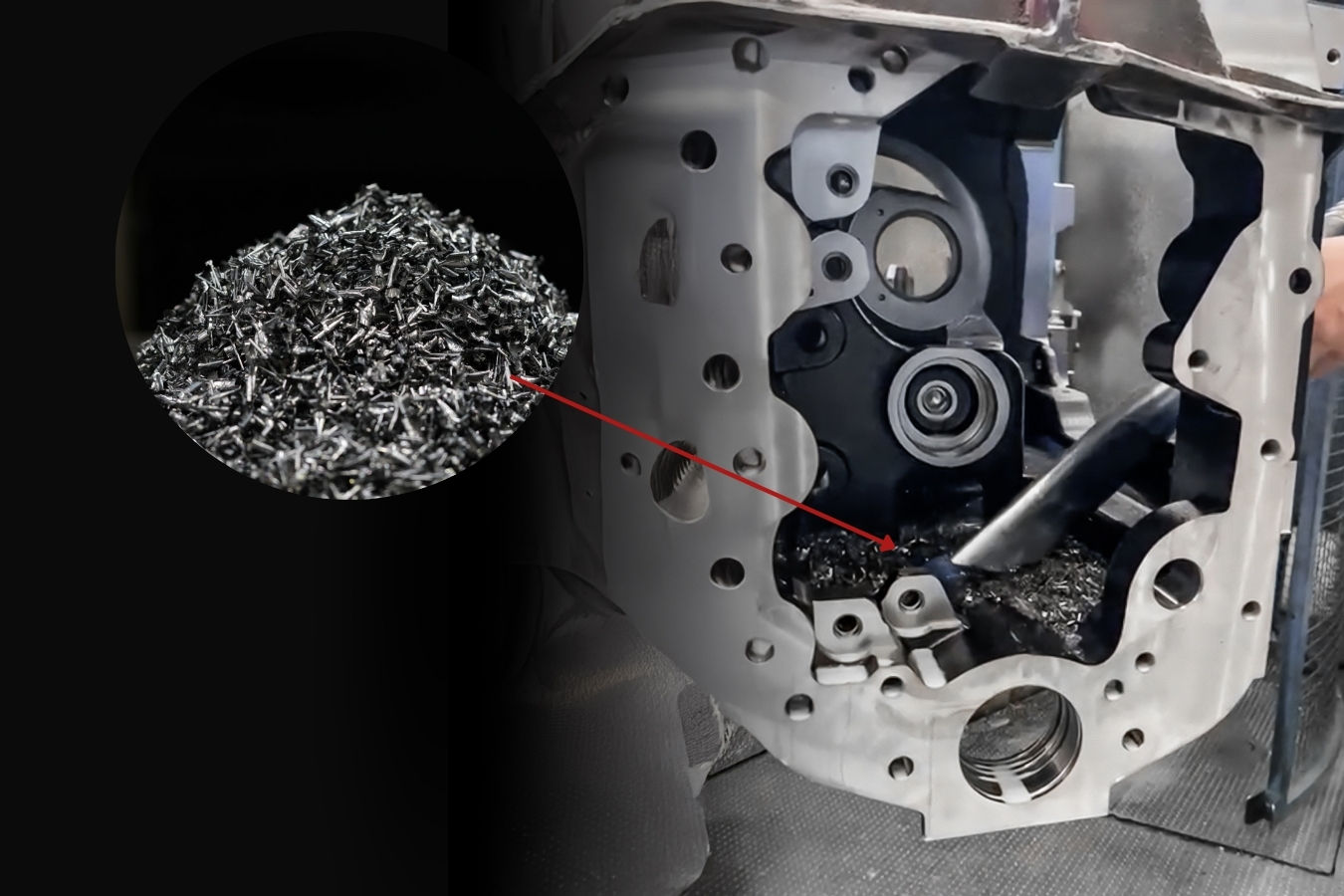

Application: Collection of carbon residues of various grain sizes in ATEX zone 22

Customer: Dealer of chemical products

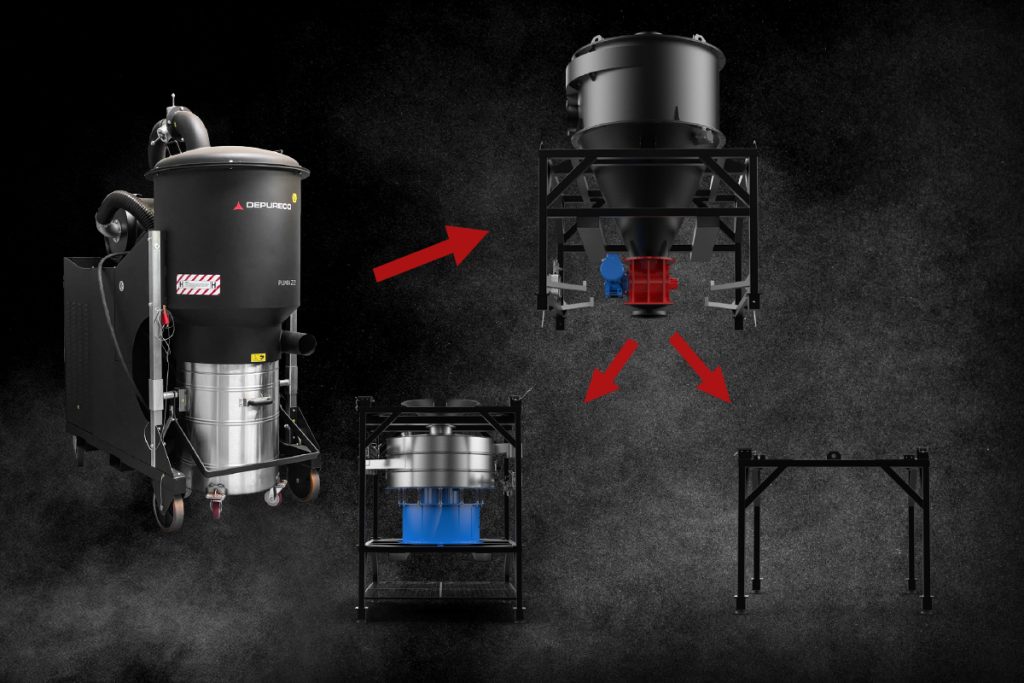

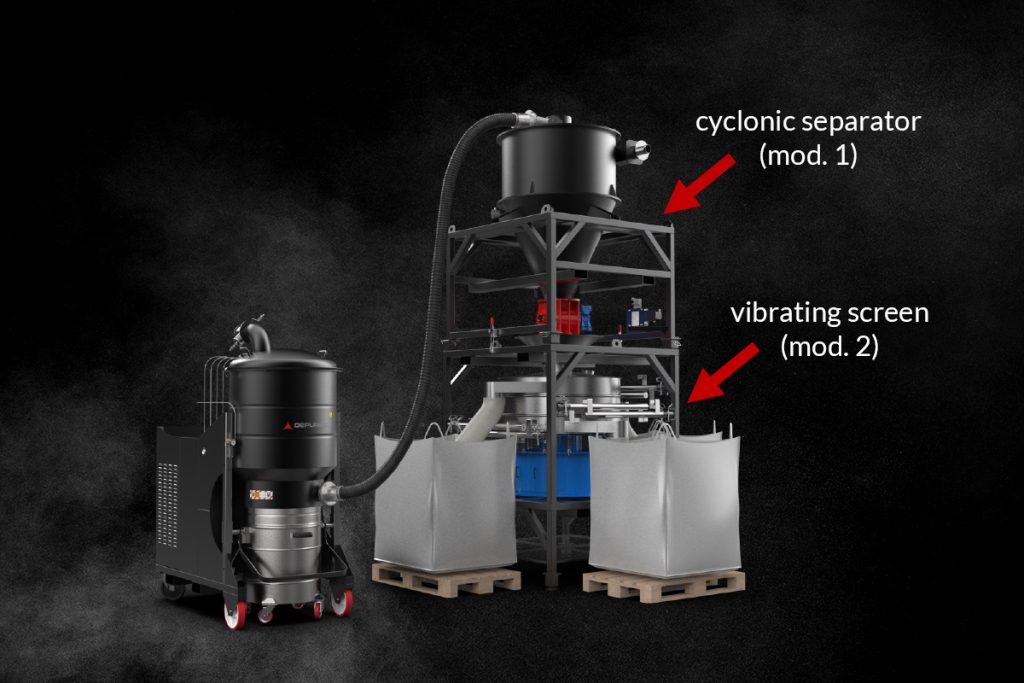

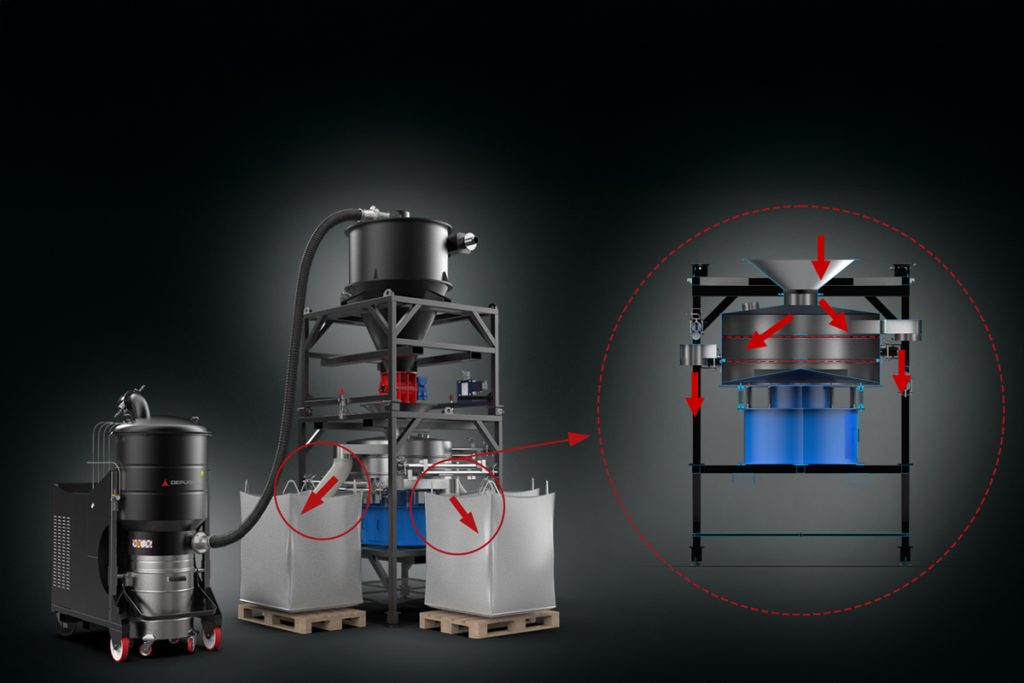

Product: Puma 30 S Atex Z22 + cyclonic separator +vibrating screen and steel frame

PROBLEM: Multi-Site Dust Collection and Granulometric Separation

The customer needed a mobile vacuum system that could operate across multiple sites and be set up quickly. The solution had to deliver the performance of a large-scale system while remaining easy to move, with a modular layout of three configurable modules to adapt to different jobs. It also had to ensure efficient collection of material in big bags, provide particle size separation when required, and guarantee maximum safety when handling potentially explosive dust in an ATEX Zone 22 area.

Key priorities included:

SAFE ATEX HANDLING

MOBILE LARGE-SCALE CAPACITY

CONTROLLED DISCHARGE AND SEPARATION

Fine carbon dust had to be captured in Zone 22 conditions without creating ignition risk.

The system needed to deliver high vacuum performance while remaining easy to move between different sites.

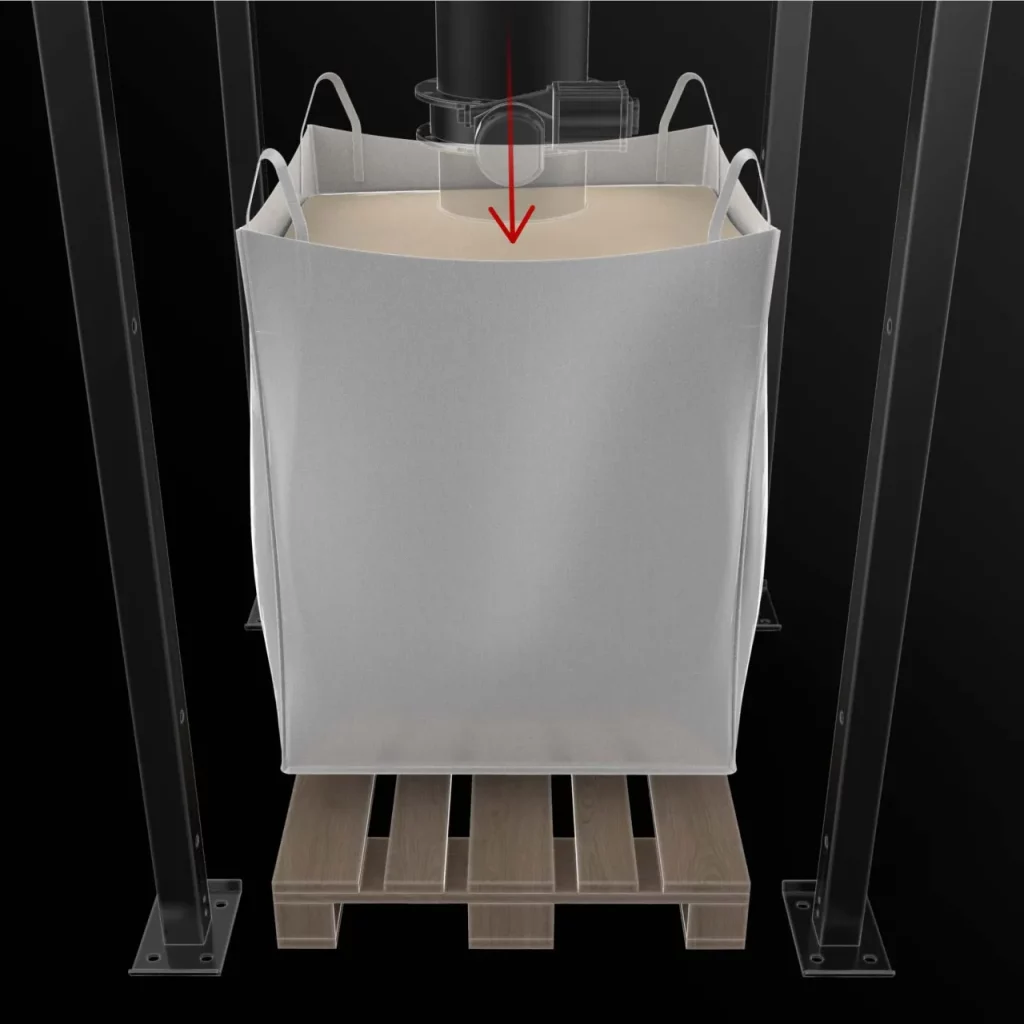

Collected carbon had to be unloaded into big bags and, when required, separated by granule size.

SOLUTION: Solution: Modular Vacuum System with Vibrating Screen

To meet the project’s requirements, a modular industrial vacuum system was developed around a PUMA 30 S ATEX 1/3D unit with an SP filter cleaning system and three modules that can be configured to match different operating needs. The entire system is rated for safe operation in ATEX Zone 22 environments, ensuring maximum protection when handling potentially explosive dust during cleaning activities.

Key features

The collected material can be separated by size using a vibrating screen, which classifies the carbon based on particle dimensions. When separation is not needed, it can be discharged directly into a single big bag.

Modularity and flexibility of the system

In this setup, Module 1 is always required as the base. Depending on the application, either Module 2 or Module 3 is then installed on top of Module 1 to meet specific needs.

Industrial Vacuum + Pre-Separator + vibrating screen

For particle size separation of carbon

Industrial Vacuum + pre-separator + steel frame

For collection without the need for separation

explore the installation

vacuum unit

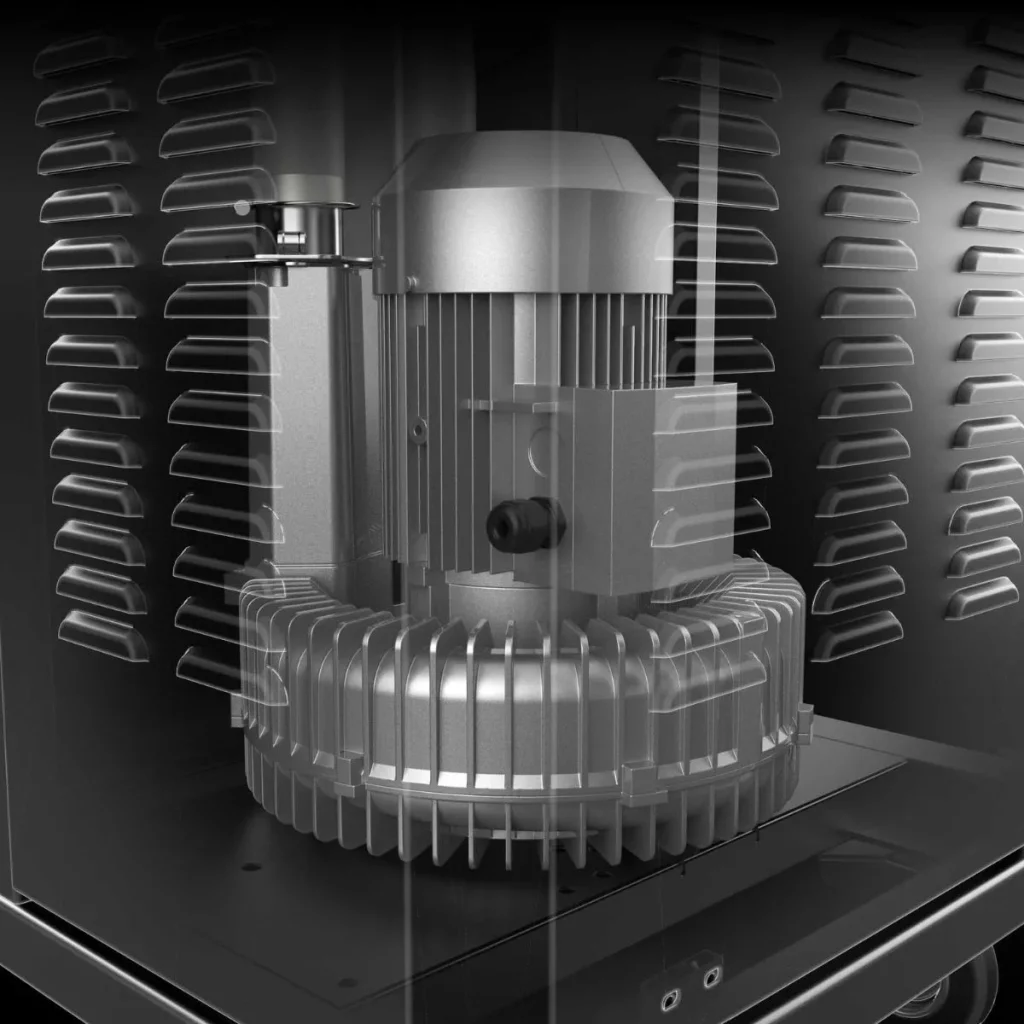

For this project, the chosen vacuum unit is the high-power industrial PUMA 30 S ATEX 1/3D, certified for heavy-duty use in ATEX Zone 22 classified areas.

- Power: 18,5 kW

- Filtering surface: 180.000 cm2

- Vacuum in continuous run: 380 mBar

- Certified for heavy-duty operation in ATEX Zone 22

Thanks to its design and powerful ATEX-certified side channel blower, the vacuum delivers reliable, high performance in continuous operation.

side channel blower

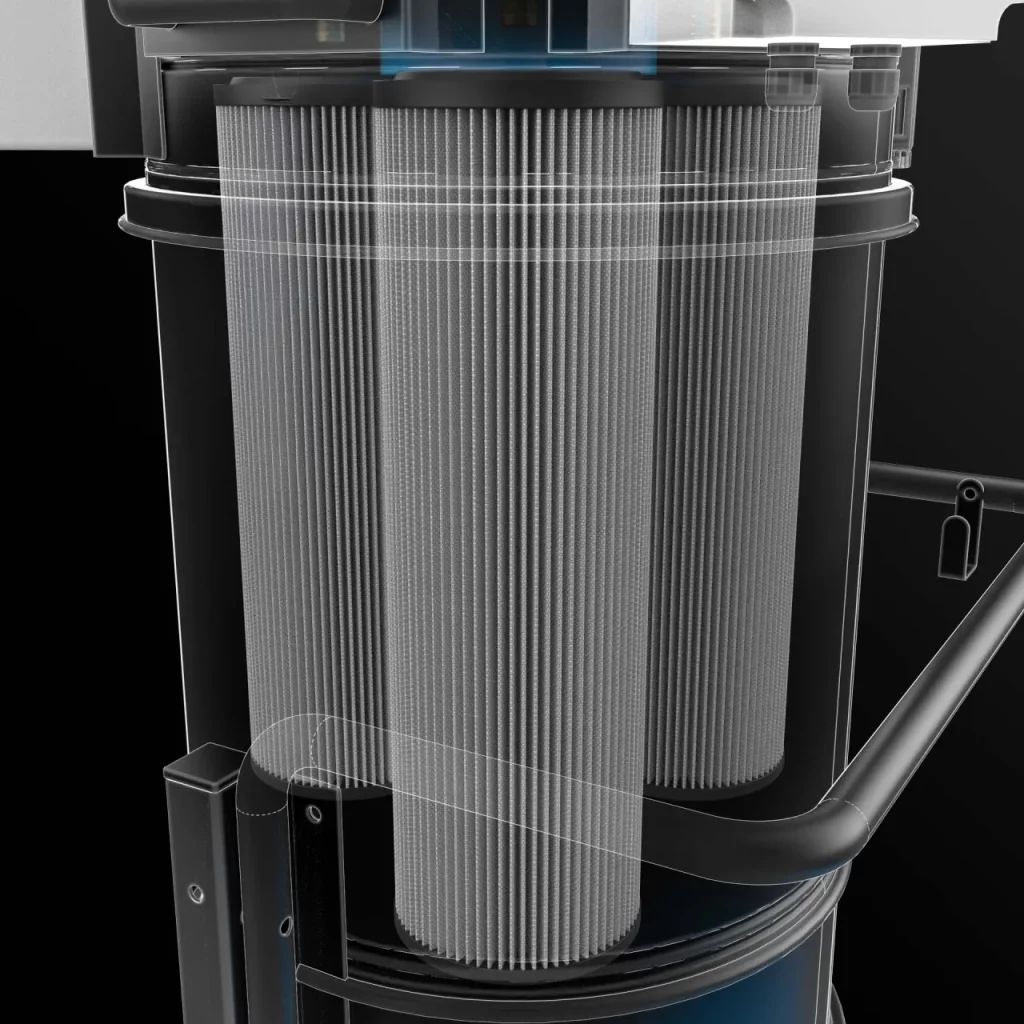

4 class M cartridges

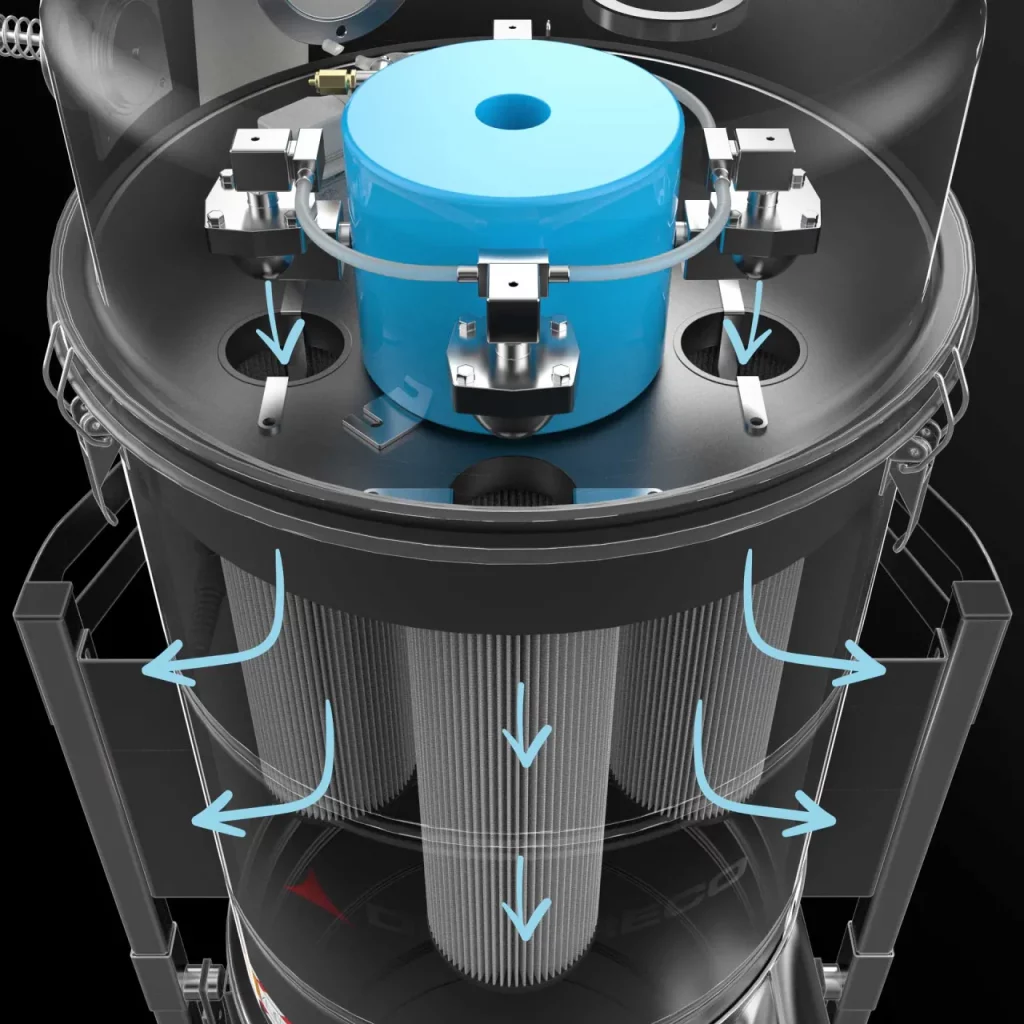

SP filter cleaning system

Certified internal protection Category 1D

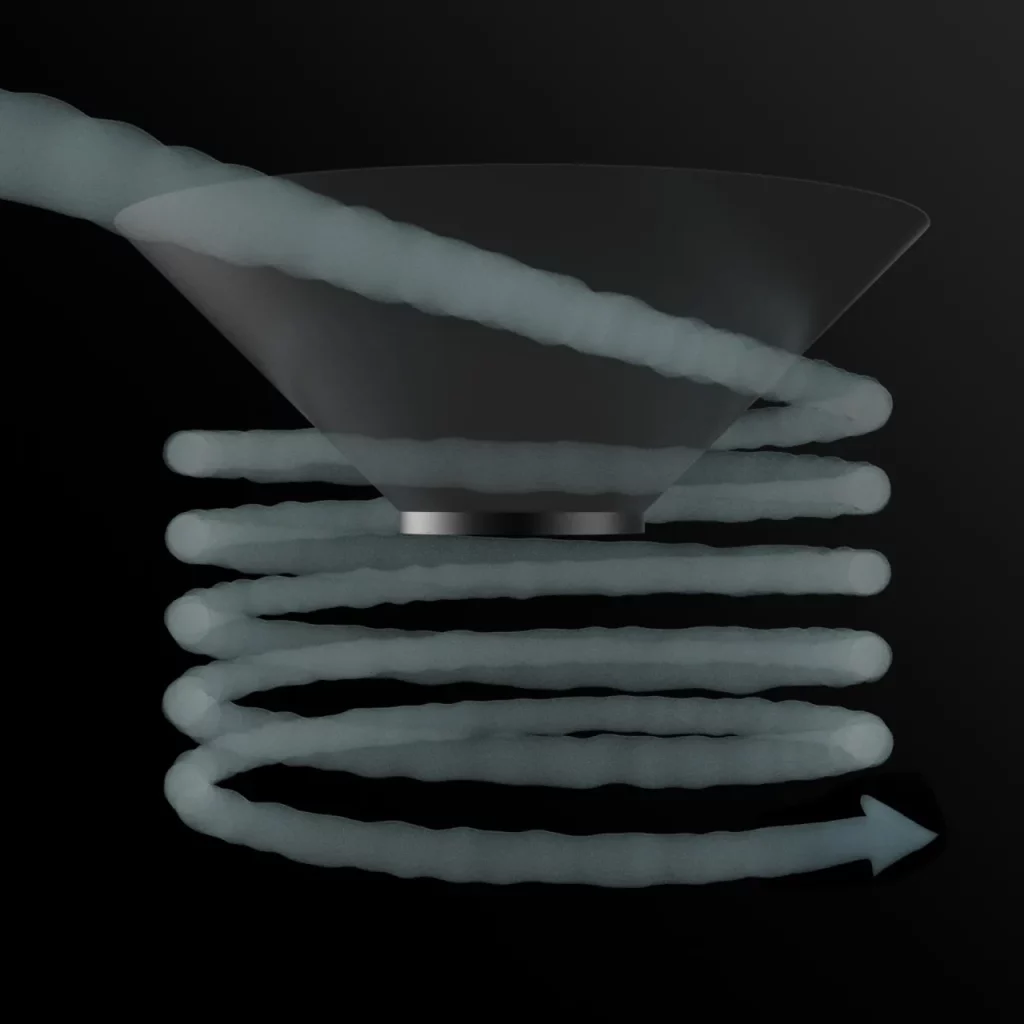

how does the vibrating screen work?

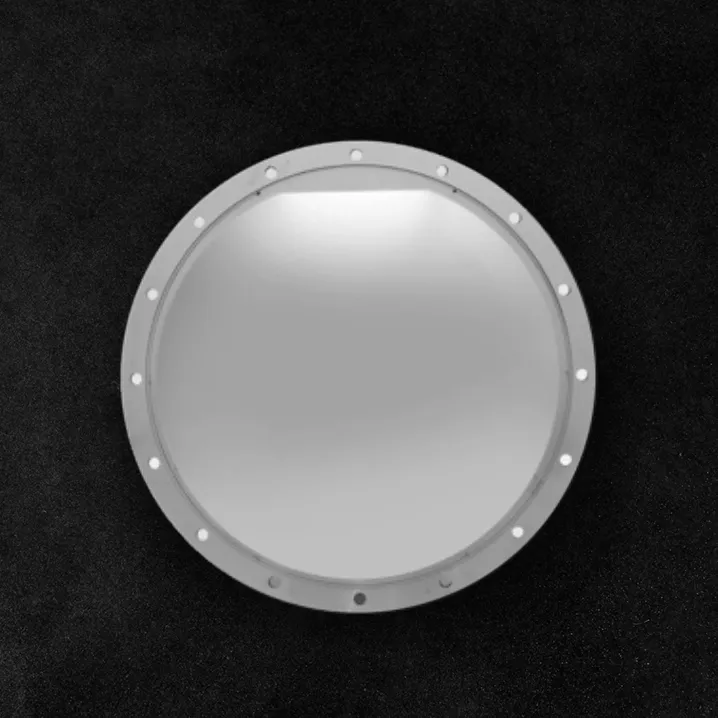

- Structure: made up of three sections with metal mesh screens, it allows accurate grading of the material.

- Operation: during operation, the vibrating screen oscillates intensely; the material coming from the separator flows over the different meshes, is gradually separated, and collected into three big bags according to particle size.

- Flexibility: the screens can be quickly replaced to adapt the cut size to the specific requirements of each process.

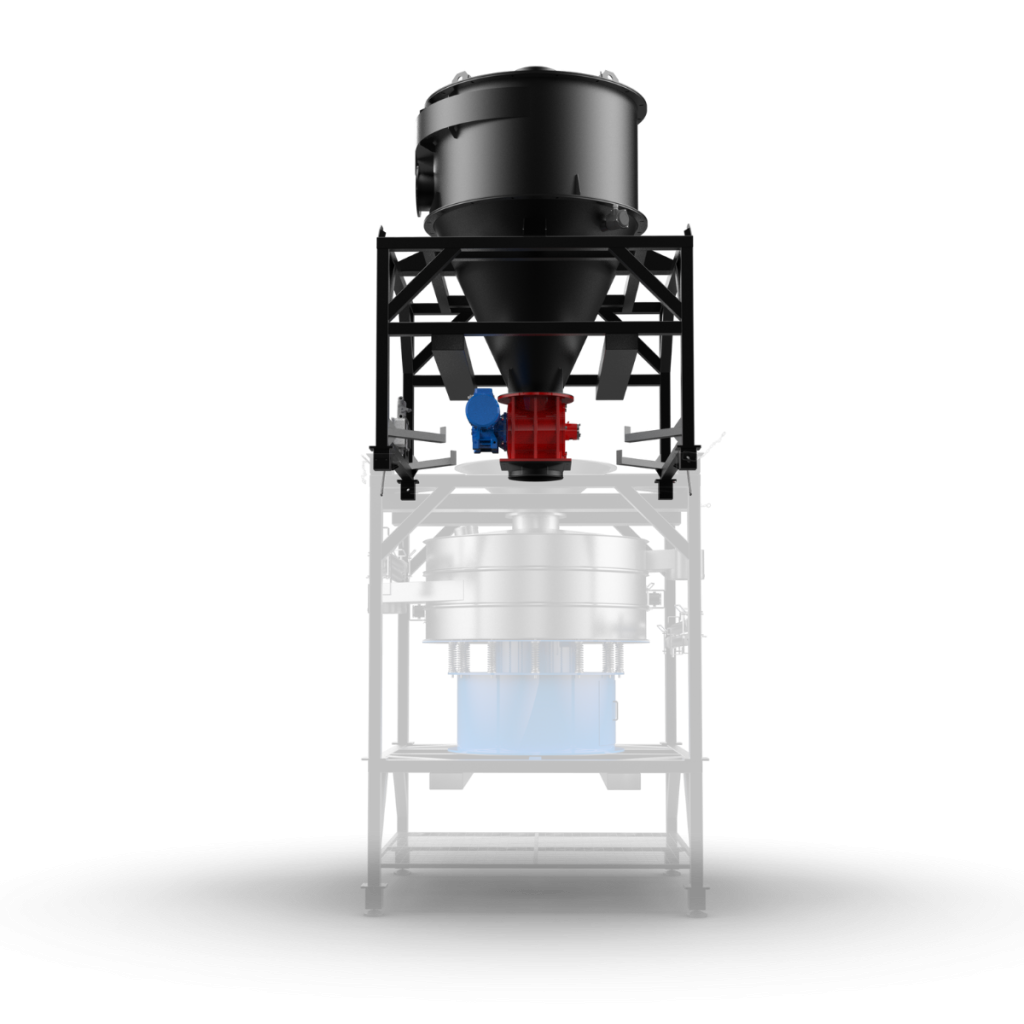

Modul 1 – Pre-separator Ø 1100

Module 1 is built around a cyclonic separator with a diameter of 1100 mm and is equipped with:

- Rotary level sensor

- Explosion relief vent

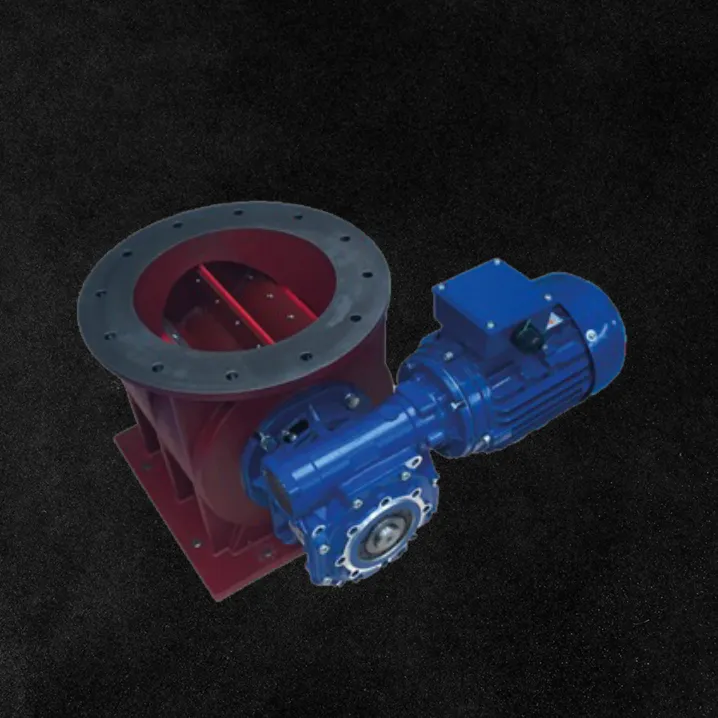

- Rotary valve continuous discharge system

The frame features an integrated tie-rod clamping system that increases stability between the modules. It also includes lifting points with eyebolts and dedicated slots for safe forklift handling.

Rotary level sensor

4 class M cartridges

Rotary discharge valve

Certified internal protection Category 1D

Modul 2 – Vibrating screen

Module 2 is equipped with an eccentric-motion vibration motor rated at 2.2 kW and 400 Volts. When used together with Module 1 (cyclonic separator), Module 2 functions as a vibrating screen, allowing the system to manage large material volumes while performing particle size separation.

- The vibrating screen is designed with three discharge outlets that distribute the vacuumed material based on particle size. Inside, three metal mesh discs are installed, which can be customized according to the required particle size class.

- The discharge outlets are fitted with three pairs of foldable arms mounted on the frame, helping keep the Big-Bags open and stable during filling.

- The vibrating screen frame also incorporates a metal support grid at the base for tools, along with four adjustable leveling feet that ensure proper setup and alignment, even on uneven floors.

Discharge outlet

Foldable arms for Big-Bags

Leveling feet

Modul 3 – Frame

Module 3 consists of a frame with leveling feet and is used when the material needs to be discharged without particle size separation (therefore without the vibrating screen).

- The frame festures are designed with guides that make it easier to align and secure Module 1, which is then locked in position using pins.

- Lifting points with eyebolts are also provided to allow safe handling with a forklift.

Alignment guides and pin-locking system

Discharge in Big-Bag

Forklift-compatible

RESULTS

Thanks to this system, our customer can safely vacuum carbon residues and, depending on their needs, either discharge them into three separate big bags, each sorted by particle size, or unload all the collected material into a single big bag.

FAQ's

How is the vibrating screen built?

It is composed of three sections with metal mesh screens, it allows precise material classification.

How does the vibrating screen separate the material?

During use, the vibrating screen vibrates vigorously; the material coming from the separator passes through the different meshes, being progressively separated and collected into three Big-Bags.

What does SP filter cleaning system mean?

It is an automatic cleaning system that operates using compressed air.