Industry: Agricultural Machinery / Tractor Manufacturing

Application: Collection and cleaning of dry metal chips from CNC-machined gearbox blocks

Customer: Leading tractor manufacturer

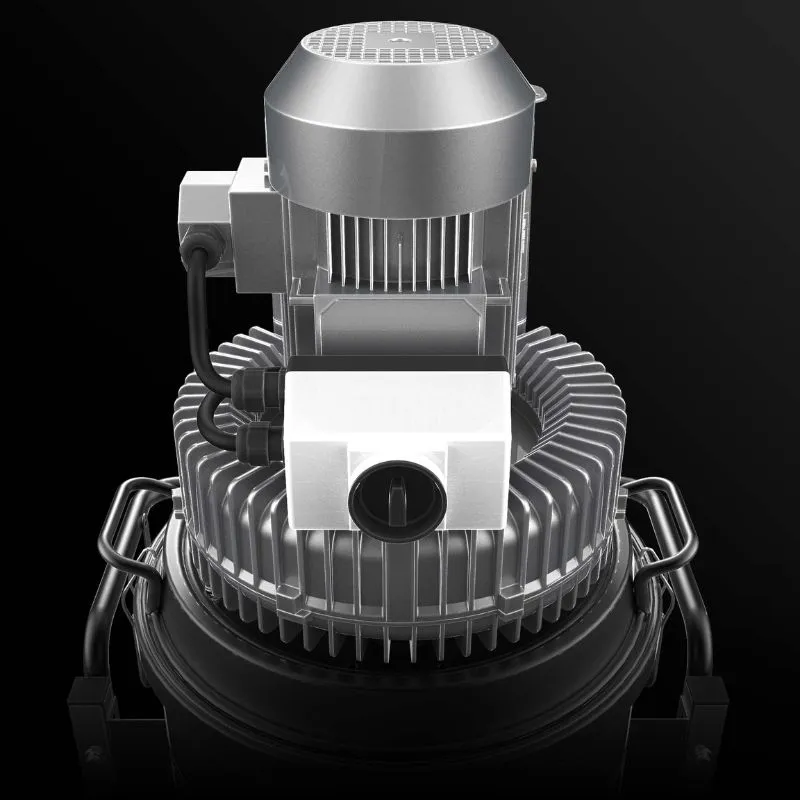

Product: Depureco HF 300 Stationary Industrial Vacuum (4 units installed)

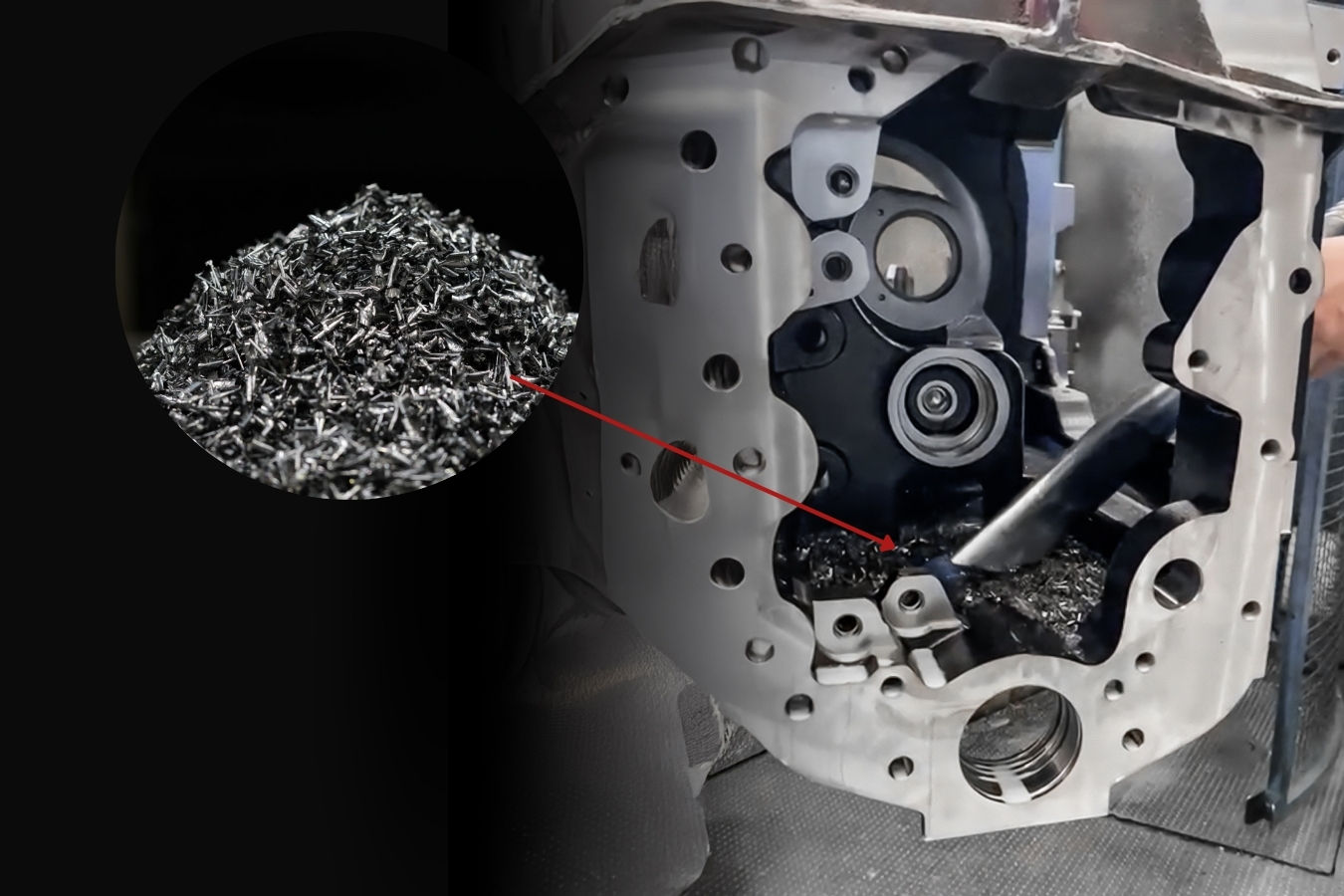

PROBLEM: DRY METAL CHIPS ON GEARBOX BLOCKS AFTER CNC MACHINING

In the final stage of gearbox production, steel and cast-iron blocks come out of CNC machining covered in dry metal chips. These residues can compromise both component quality and production efficiency.

Leftover chips cause scratches on precision surfaces, clog tooling, and delay assembly. Manual cleaning required operators to stop machines and remove chips by hand—costing time, consistency, and safety.

The manufacturer needed a fast, automated way to clean gearbox blocks directly at each CNC station, preventing defects and keeping production moving.

Key priorities included:

PREVENTING DAMAGE

AVOIDING BLOCKAGES

MAINTAINING PRODUCTIVITY

Residual metal chips could harm sensitive gear and bearing seats.

Accumulated swarf risked clogging fixtures and coolant channels.

Quick chip removal was essential to sustain continuous operation and meet cycle times.

SOLUTION: FOUR HF 300 STATIONARY VACUUMS FOR DRY CHIP COLLECTION

Depureco engineered a dedicated chip-cleaning solution integrated with every CNC machine. Four HF 300 stationary vacuums—one per machine—were installed to collect and discharge dry metal chips directly into each CNC’s collection system.

Key features and performance highlights:

Continuous high-power suction: Each HF 300 is equipped with a 4.8 HP side-channel blower, ensuring strong and stable suction even with long piping runs.

Fast cleaning cycles: The system can completely clean the surface of a gearbox block in under two minutes, minimizing idle time between machining and assembly.

Optimized for fine, dry chips: Designed to handle steel, cast-iron, and aluminum swarf without clogging or loss of suction power.

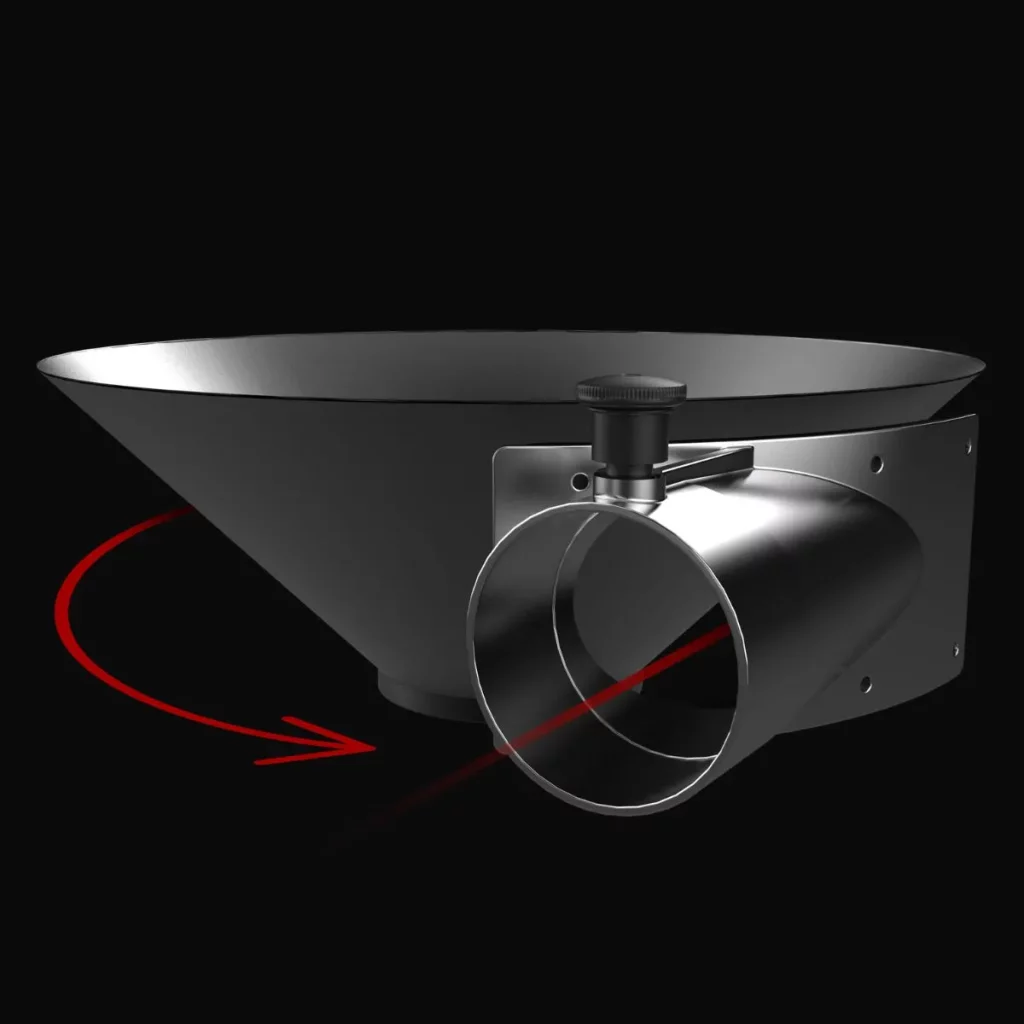

Tangential inlet with cyclone effect: Directs airflow to drop heavier particles before the filter, maintaining steady performance and filter life.

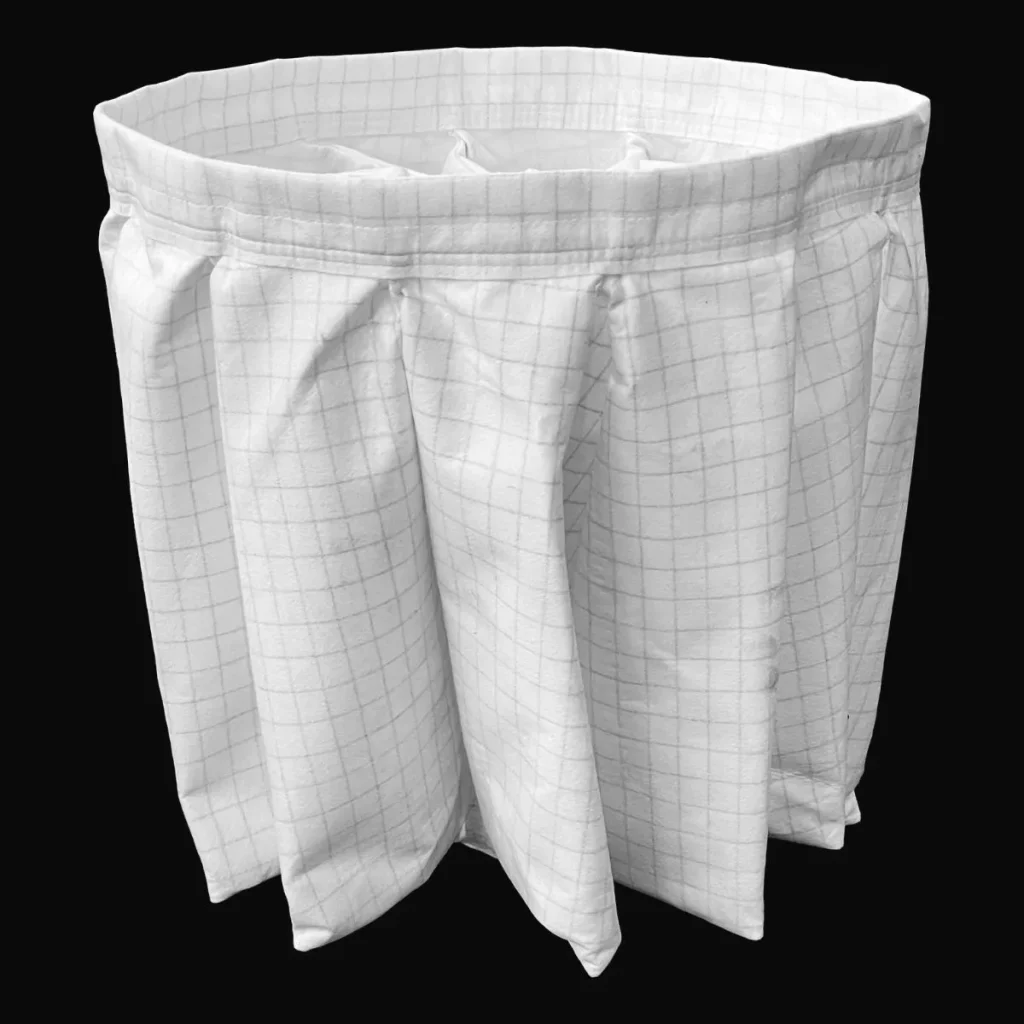

M-Class polyester star filter: Provides filtration efficiency down to 1 micron, protecting the blower and maintaining clean exhaust air.

Manual filter shaker: Quick, tool-free cleaning ensures constant suction and reduced maintenance.

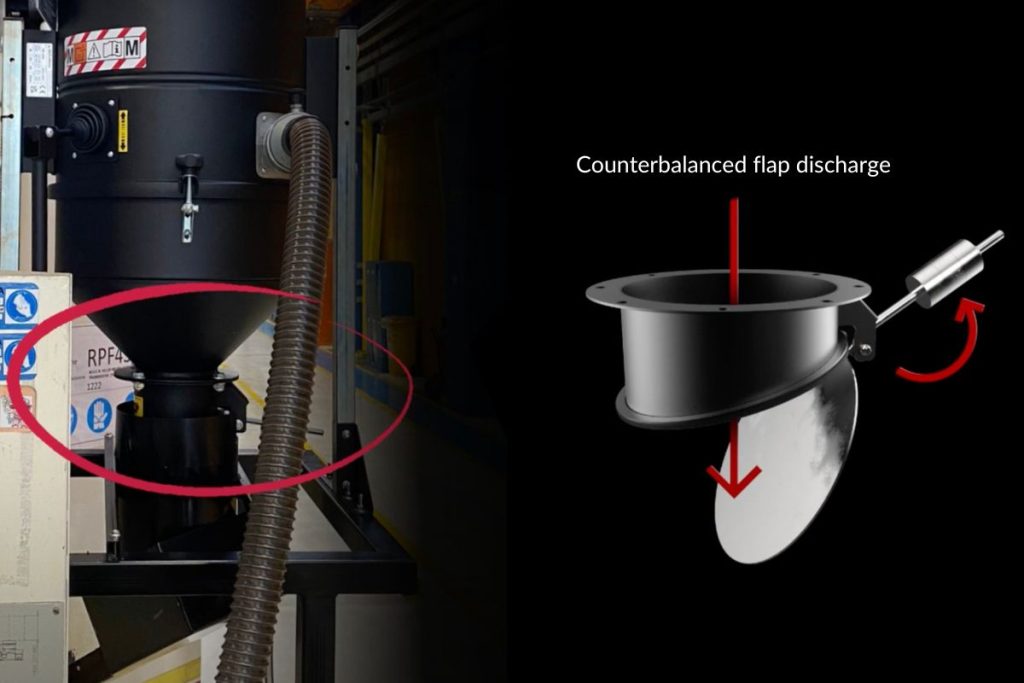

Counterbalanced flap discharge system: When suction stops, the flap opens automatically, dropping collected chips into the CNC’s collection hopper—no manual handling required.

This configuration allowed the customer to remove dry metal chips directly at the machine with a short cleaning cycle and automatic discharge. The system operates continuously and requires virtually no operator intervention.

FOCUS: SPEED, SAFETY, AND CLEAN PRODUCTION

The installation of four HF 300 vacuums provided the tractor manufacturer with a faster, cleaner, and safer finishing process. Each unit keeps CNC work zones free from loose metal chips, preventing surface damage and improving overall component quality.

By eliminating manual chip cleaning, operators spend less time handling waste and more time on production tasks. The automated discharge system also prevents downtime—chips are collected, released, and evacuated seamlessly between machining cycles.

As a result, the manufacturer achieved:

Shorter cleaning cycles and zero manual rework

Reduced maintenance and operator fatigue

Improved surface quality of machined gearbox blocks

Consistent suction performance for dry, fine metal chips

A cleaner, safer workspace and continuous workflow

The HF 300 central vacuum system for metal chips proved to be the ideal solution for maintaining productivity and protecting product integrity in high-precision tractor manufacturing.

EQUIPMENT HIGHLIGHTS

HF 300 Stationary Industrial Vacuum

Power: 4.8 HP three-phase side-channel blower

Filter surface: 3,720 in²

Filter type: M-Class polyester star filter (1 µm efficiency)

Inlet: Tangential cyclone inlet

Discharge: Counterbalanced flap system for automatic emptying

Construction: Heavy-duty steel, grounded for safety

Performance: Continuous duty, ideal for fine and dry metal chips

Metals handled:

Steel • Cast Iron • Aluminum • Brass • Copper • Stainless Steel

RESULTS

The HF 300 installation allowed the manufacturer to completely clean gearbox blocks in less than two minutes per cycle while operating four machines in parallel. Manual chip handling was eliminated, and maintenance downtime dropped significantly. Clean, chip-free components moved directly to assembly, improving product quality and production flow. The automated discharge kept the vacuums running continuously, ensuring constant suction and reliable performance—even in demanding, multi-shift environments.

FAQ's

What metals can the HF 300 collect?

It efficiently handles fine, dry chips from steel, cast iron, aluminum, copper, brass, and stainless steel machining.

How long does it take to clean each gearbox block?

Less than two minutes per part, with four CNC machines operating simultaneously.

Does the vacuum operate continuously?

Yes. The HF 300 runs in continuous duty with automatic discharge to avoid interruptions.

How does the discharge system work?

When suction stops, the counterbalanced flap opens, releasing chips directly into the CNC’s collection system—no manual emptying required.

What filtration system is used?

An M-Class polyester star filter with 1 µm efficiency protects the blower and ensures long-term performance with a manual shaker for easy cleaning.