DOWNLOAD OUR CASE STUDY

In a metalworking setting where welding torches are utilized, the creation of welding fumes poses a considerable hazard. These fumes carry dangerous substances and heavy metals that, when breathed in, can result in respiratory issues and other health complications.

Installing a centralized welding fume extraction system is vital for protecting the welfare of workers. These systems efficiently nab and eliminate perilous fumes from various sources at once.

When companies invest in welding fume extractors, they not only comply with safety regulations but also demonstrate a firm commitment to providing a safe and secure work environment for their employees.

A welding fume extraction system:

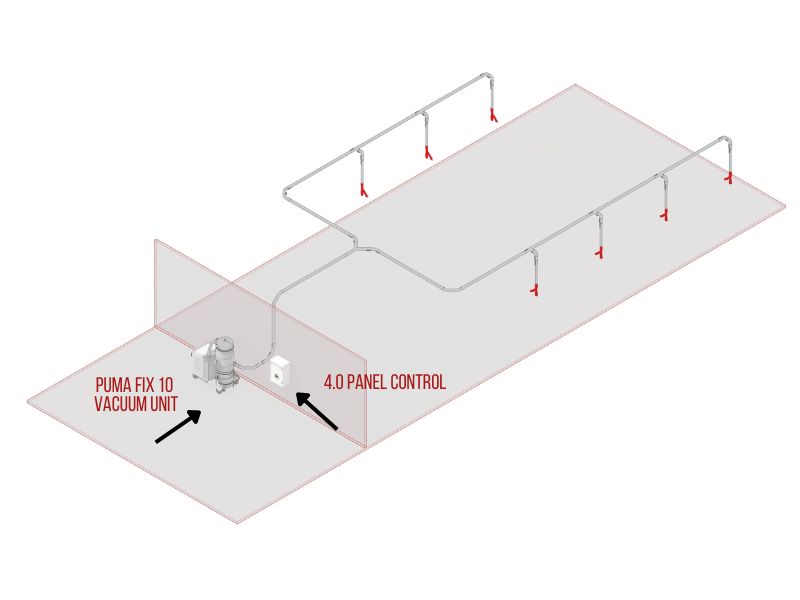

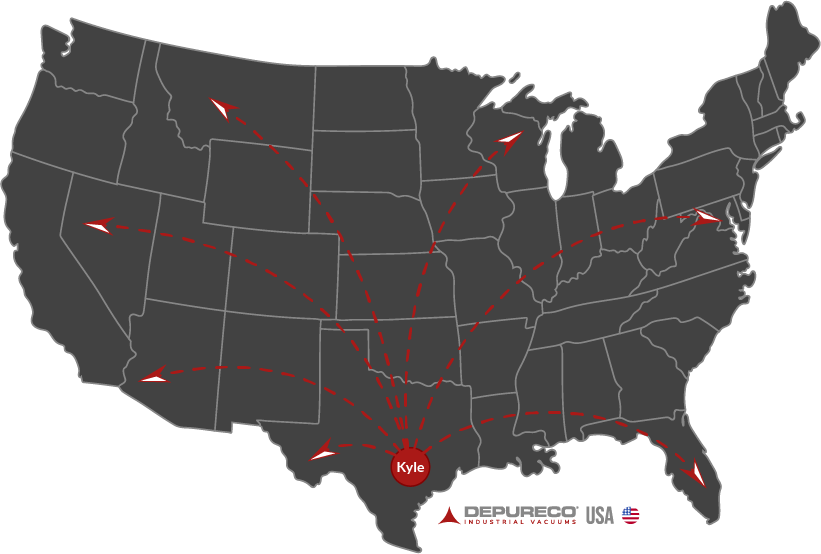

Our client, a metalworking industry, required a solution to gather welding fumes from numerous welding stations simultaneously, utilizing a single extraction unit. They chose a centralized vacuum system to guarantee superior air quality in the welding zone.

We will give you all the required information