The Industry’s Shield Against Volatile Particulate Hazards

Depureco USA provides engineered safety shields designed to capture volatile particulates at the source. While we finalize our specific U.S. electrical certifications, our entire lineup is built to exceed the NFPA 660 mandates and utilizes HEPA 14 absolute filtration to ensure your facility meets its Dust Hazard Analysis (DHA) goals.

Our air-powered units use no electricity and generate no heat, making them inherently safe for the most sensitive Class I and Class II environments without requiring electrical certification.

Every unit features integrated grounding from the tangential inlet to the exhaust, eliminating the arcing and static discharge that triggers dust-air ignitions.

| Industry Sector | Hazardous Material Profile | Required Safety Standard |

|---|---|---|

| Additive Mfg & Metals | Aluminum, Titanium, Iron Dust, & Stainless Steel | NFPA 484 / 660 |

| Food, Grain & Pharma | Flour, Sugar Dust, Protein Powder, & Starch | NFPA 61 / 660 |

| Energy & Battery | Lithium-Ion Battery Dust & Carbon Fibers | NFPA 654 / 660 |

| Surface Tech | Silica Dust, Powder Coatings, & Concrete | OSHA NEP / 660 |

| Defense & Range | Lead Dust, Gunpowder, & Brass Debris | OSHA 1910.1025 / 660 |

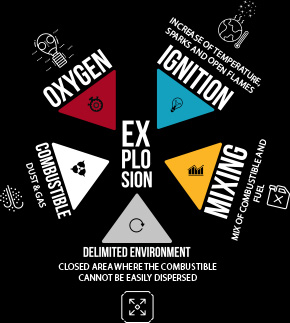

Understanding how an explosion occur is the first step toward prevention, but awareness alone doesn’t secure a facility. To achieve true operational safety, you must systematically neutralize the five elements required for a dust explosion—known as the Explosion Pentagon.

Depureco USA systems are engineered to target and eliminate these specific variables through advanced particulate control.

By disrupting the Explosion Pentagon at multiple points, Depureco USA engineering provides more than just a vacuum—it provides an insurance-grade safety barrier for your facility.

Whether you are performing a Dust Hazard Analysis (DHA) or upgrading your facility to meet new NFPA 660 compliance standards, our technical experts can help you select the exact hardware to neutralize your specific material risks.