COMBUSTIBLE DUST

Industrial vacuums designed for combustible dust are essential for maintaining safety in environments where explosive hazards exist. These specialized vacuums are equipped with features that mitigate the risks associated with combustible dust, such as powerful suction capabilities and explosion-proof designs. They are constructed with materials that prevent static buildup and incorporate anti-static hoses to prevent sparks that could potentially ignite combustible dust particles.

Combustible dust poses a significant threat to health and safety in manufacturing environments, making it a top concern for Health and Safety managers responsible for safeguarding workers and production plants. Unfortunately, accidents resulting from inadequate safety measures are not uncommon, and the tragic Imperial Sugar disaster in 2008, which claimed 14 lives due to an explosion caused by sugar dust, served as a stark reminder of the urgent need for stricter standards and policies to prevent such catastrophic events. In response, organizations like OSHA (Occupational Health and Safety Administration) and the NFPA (National Fire Protection Association) have taken proactive measures, developing comprehensive monitoring programs across North America to ensure the utmost safety in industrial manufacturing processes. Industrial vacuum systems have emerged as a critical component in these initiatives, as they can be both a potential source of ignition if not properly equipped and the most effective and recommended method for safely removing hazardous dusts.

In response to this disaster, regulatory bodies like OSHA (Occupational Health and Safety Administration) and the NFPA (National Fire Protection Association) initiated monitoring programs across North America to ensure the highest possible level of safety in industrial manufacturing processes. Industrial vacuum systems became an integral part of these policies as they embody both:

✓ A potential source of ignition if not equipped with necessary safety features

✓ The optimal and recommended cleaning method for effectively removing hazardous dust

By recognizing the dual role of industrial vacuum systems, organizations strive to mitigate the risk of ignition while acknowledging the importance of thorough and safe dust removal. These measures aim to enhance safety standards and reduce the likelihood of devastating incidents in manufacturing environments.

NFPA 660, the new combustible dust standard, is a crucial regulation that addresses the hazards associated with combustible dust in various industries. Introduced by the National Fire Protection Association (NFPA), this standard provides comprehensive guidelines for managing and mitigating the risks posed by combustible dust in industrial settings. NFPA 660 emphasizes the importance of identifying and evaluating potential hazards, developing effective control strategies, and implementing appropriate preventive measures. It appoints vacuum cleaners as one of the recommended cleaning methods of combustible dust.

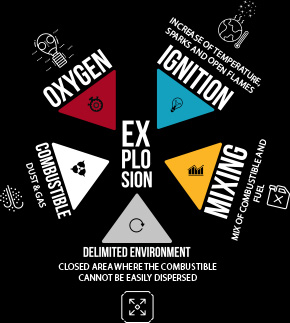

The pentagon of explosion represents five essential elements necessary for an explosion to occur: fuel, oxygen, an ignition source, dispersion, and confinement. Fuel refers to combustible materials present in the environment, such as dust or gases. Oxygen, a vital component for combustion, is typically present in the air. An ignition source, such as a spark or heat, is needed to initiate the reaction. Dispersion refers to the process by which the fuel particles or gases become suspended in the air. Lastly, confinement refers to the containment of the fuel-air mixture within a confined space, allowing pressure to build up and leading to an explosion.

Anti-static, safe, with exceptional performances and filtration. Discover the best solution for your industry!

We will give you all the required information