Wood shops generate large volumes of dust — from fine sanding particles to heavy saw chips — that can pose health risks, fire hazards, and equipment damage if not properly controlled. Whether you’re running a CNC router, table saw, or edge sander, an industrial dust collection system ensures a clean, compliant, and efficient workspace.

Depureco dust collectors are built to handle the toughest woodshop conditions, with powerful airflow, high-efficiency filtration, and optional HEPA or antistatic configurations.

Wood dust is highly combustible — and when it accumulates in the air or on surfaces, it becomes a serious explosion risk. That’s why dust collection systems aren’t just about cleanliness — they’re about safety and compliance.

The NFPA 660 standard (formerly NFPA 664 and others) outlines strict fire and explosion prevention guidelines for facilities that generate combustible dust, including woodworking shops. A properly designed industrial dust collector helps:

✅ Capture airborne fine dust before it disperses

✅ Prevent dangerous surface accumulation

✅ Support compliance with NFPA 660 and OSHA standards

✅ Reduce ignition risks near cutting, sanding, and grinding stations

By integrating an NFPA-compliant dust collection system, woodshop owners can proactively protect their teams, minimize downtime, and reduce liability — while maintaining a clean and safe workspace.

Sawing operations — whether with table saws, band saws, or miter saws — generate large volumes of wood chips and fine dust. This dust not only settles on equipment and surfaces but can linger in the air, creating a respiratory hazard and a potential fuel source for combustion.

Wood lathes create a steady stream of fine dust and long, curled shavings that can quickly accumulate around the tool rest, motor housing, and operator workspace. Unlike saws or sanders, lathe dust disperses in a wide radius — making source-capture dust collection essential.

Installing a vacuum system with a flexible hose arm or downdraft collection point near the cutting zone helps minimize airborne dust and keeps the work area clear of shavings. This reduces cleanup time, improves visibility, and helps protect operators from respiratory exposure.

Compliance to latest NFPA safety regulations with combustible dust, user-friendly controls, anti-static construction, ergonomic designs, and large collection capacities, industrial vacuum solutions empower wood shop operators to effectively manage and eliminate combustible dust, promoting a safer working environment and reducing the risk of dust-related accidents and health hazards.

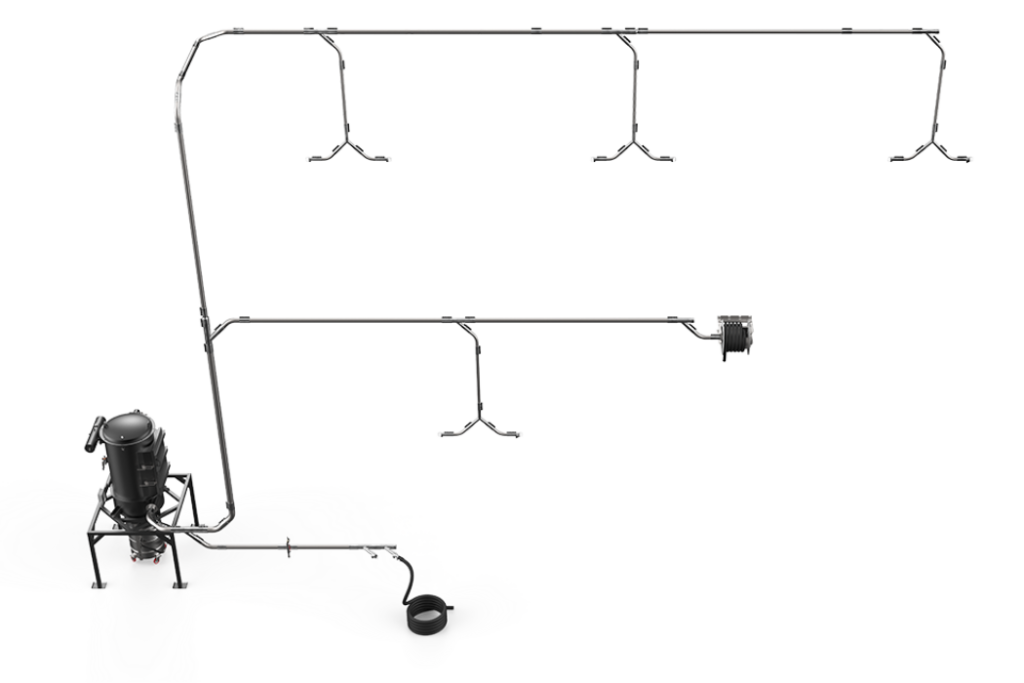

For large woodshops or multi-station production facilities, a centralized vacuum system is one of the most efficient and scalable solutions for managing wood dust and chips.

Unlike portable units, central vacuum systems provide automated, continuous dust extraction across your entire workspace. With strategically placed inlet points near table saws, CNC routers, lathes, and sanders, these systems capture fine particles and chips at the source — keeping walkways, tools, and machinery clean.

Central vacs are ideal for handling combustible wood dust safely, thanks to their powerful suction, integrated cyclonic pre-separation, and optional HEPA or M-class filtration. They also reduce maintenance and noise clutter by placing collection and motor units in a remote location.

✅ Boost efficiency with centralized suction

✅ Comply with NFPA 660 and OSHA standards

✅ Improve air quality and workplace cleanliness

✅ Scale your system with custom piping and modular components

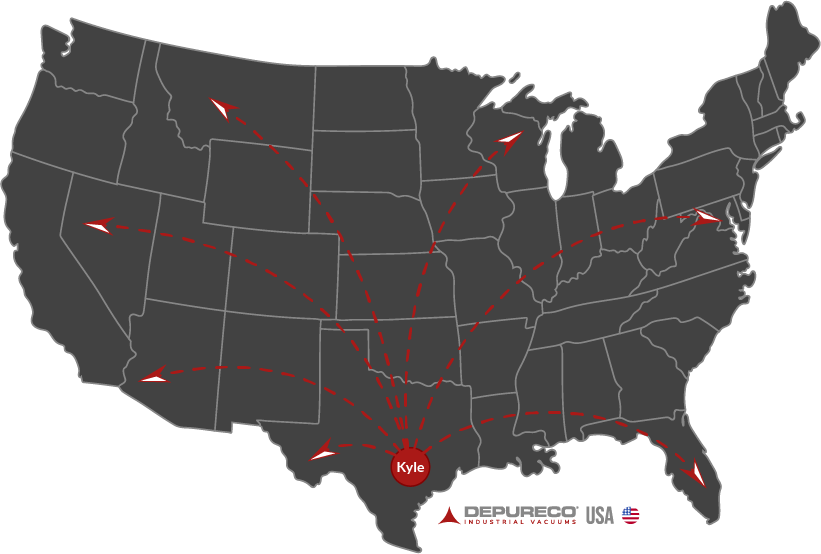

Whether you’re expanding a facility or upgrading from standalone units, Depureco can help you design a central vacuum system tailored to your shop layout and applications.

Need help finding the right vacuum, dust collector, or central system for your woodworking application? Tell us about your equipment, shop size, and dust challenges — and our team will recommend the best solution to match your needs, compliance requirements, and budget.

We will give you all the required information