DIRECT EXTRACTION

The suction of dust at the source is of utmost importance when dealing with floor preparation equipment. As these machines perform tasks such as grinding, sanding, or polishing, they generate a significant amount of airborne dust particles. Without proper extraction, this dust can not only hinder the visibility of the work area but also pose serious health hazards to workers. Inhaling fine dust particles can lead to respiratory issues and long-term health problems. By employing effective dust extraction systems, the dust is captured right at its origin, preventing it from dispersing into the surrounding environment.

Floor preparation equipment such as grinders, sanders, or polishers create a significant amount of dust particles during operation. These particles can be harmful to both the workers and the environment. By utilizing a dust extractor, the dust is captured directly at the source, preventing it from spreading into the air and settling on surfaces. This ensures a cleaner and safer working environment, reducing the risk of respiratory issues and maintaining overall health.

Dust extraction systems help to maintain the efficiency and performance of the floor preparation equipment itself. Accumulation of dust can clog the equipment’s moving parts, filters, and motors, leading to decreased effectiveness and potential breakdowns. By using a dust extractor, the equipment remains free from dust build-up, ensuring optimal performance and longevity.

Incorporating a dust extractor enhances productivity and saves time. Without proper extraction, workers would need to stop periodically to clean up the dust, disrupting the workflow and causing unnecessary delays. A dust extractor eliminates the need for constant cleaning, allowing uninterrupted operation and improving overall efficiency.

During the operation of hand tools like grinders and saws, a considerable quantity of dust is produced. To address this issue, specialized portable vacuum cleaners for fine construction dust have been developed specifically for use with hand tools. These vacuum cleaners can be conveniently attached directly to the tool, allowing them to capture dust particles as soon as they are generated. Equipped with high-efficiency particulate air (HEPA) filters, these extractors ensure exceptional filtration, effectively capturing even the finest dust particles.

Floor scarifying machines are employed to eliminate surface coatings like paint or adhesives, a task that results in the production of substantial dust. This dust can pose safety risks and contribute to environmental pollution. To address this concern, vacuum cleaners specifically designed for use with floor scarifying machines have been developed. These vacuum cleaners are equipped with robust suction power and specialized filtration systems, enabling them to effectively capture and contain the generated dust. By doing so, these vacuum cleaners ensure a secure and clean working environment for workers while also preventing the dispersal of dust into the surrounding area, thus minimizing environmental pollution.

During the utilization of floor grinders to level and refine surfaces, a substantial volume of dust is produced. To address this issue, vacuum cleaners specifically designed for floor sanders have been developed. These vacuum cleaners possess high-powered suction capabilities, specialized filters for capturing very fine dust, and automatic filter cleaning systems. These features work in harmony to enhance the efficiency and longevity of the machine while expanding the working range of the system. By effectively removing dust, these vacuum cleaners contribute to a more productive and durable floor grinding process, allowing for improved results and an extended operational lifespan of the equipment.

Floor shot blasters play a crucial role in leveling and refining surfaces. To enhance the performance and longevity of these machines, vacuum cleaners designed specifically for grinders have been developed. These vacuum cleaners are equipped with robust suction capacities, specialized filters, and automatic filter cleaning systems. These features work in tandem to optimize the efficiency and durability of the equipment. By effectively capturing dust and debris, these vacuum cleaners contribute to a more efficient and long-lasting floor shot blasting process. This ensures superior results and extends the lifespan of the machinery.

Core drilling is a method employed to bore holes in challenging surfaces such as concrete. During this process, a substantial quantity of dust is generated, which often combines with the water utilized for cooling the system. To address this issue, vacuum systems specifically designed for coring operations have been developed. These specialized vacuums possess the capability to simultaneously suction both liquids and dust. By efficiently vacuuming the mixture of water and dust, these vacuums ensure a cleaner and safer working environment during core drilling activities.

When selecting a dust extractor, there are several factors to consider to ensure you choose the right one for your needs. Here are some key points to keep in mind:

Airflow and Suction Power: Look for a dust extractor with sufficient airflow and suction power to effectively capture the dust generated by your specific equipment. Consider the size and power requirements of your tools and select an extractor that can handle the volume of dust produced.

Filtration System: Opt for a dust extractor with an efficient filtration system and automatic filter cleaning system. High-quality filters, such as HEPA filters, are ideal as they can capture even the finest dust particles, ensuring a cleaner and safer working environment. Check the filtration rating and ensure it meets your requirements.

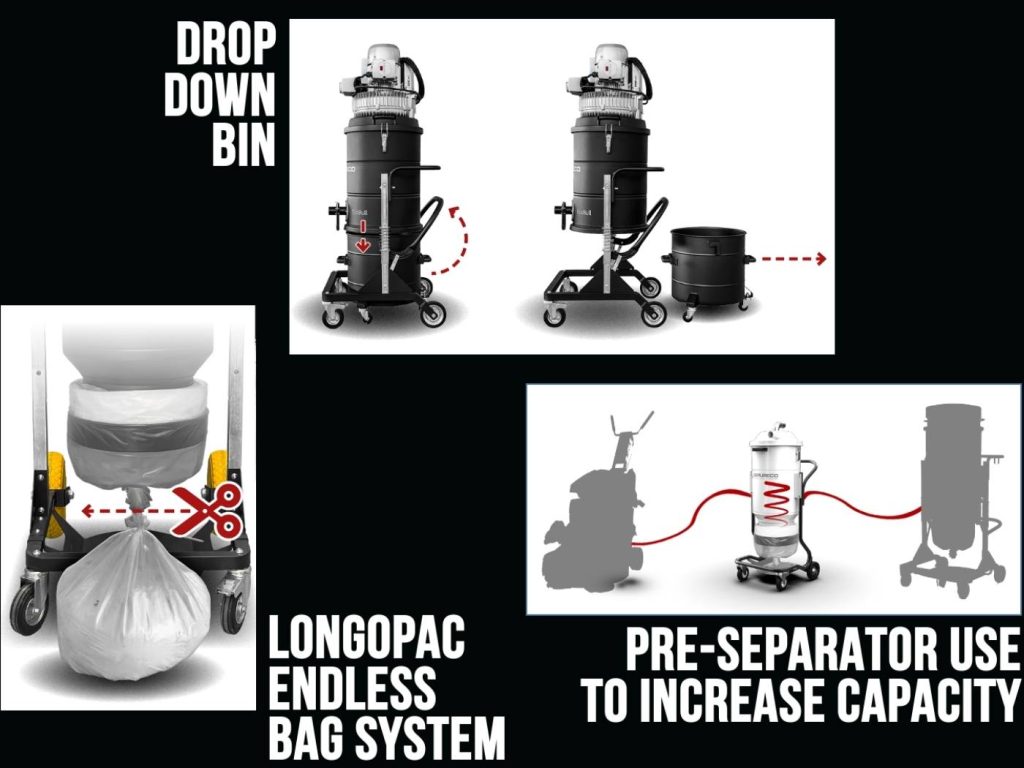

Dust Collection Capacity: Consider the size of the dust collection container or bag. A larger capacity will allow for longer work sessions without the need for frequent emptying or changing of bags. However, bear in mind that larger capacities may also mean a bulkier and heavier unit.

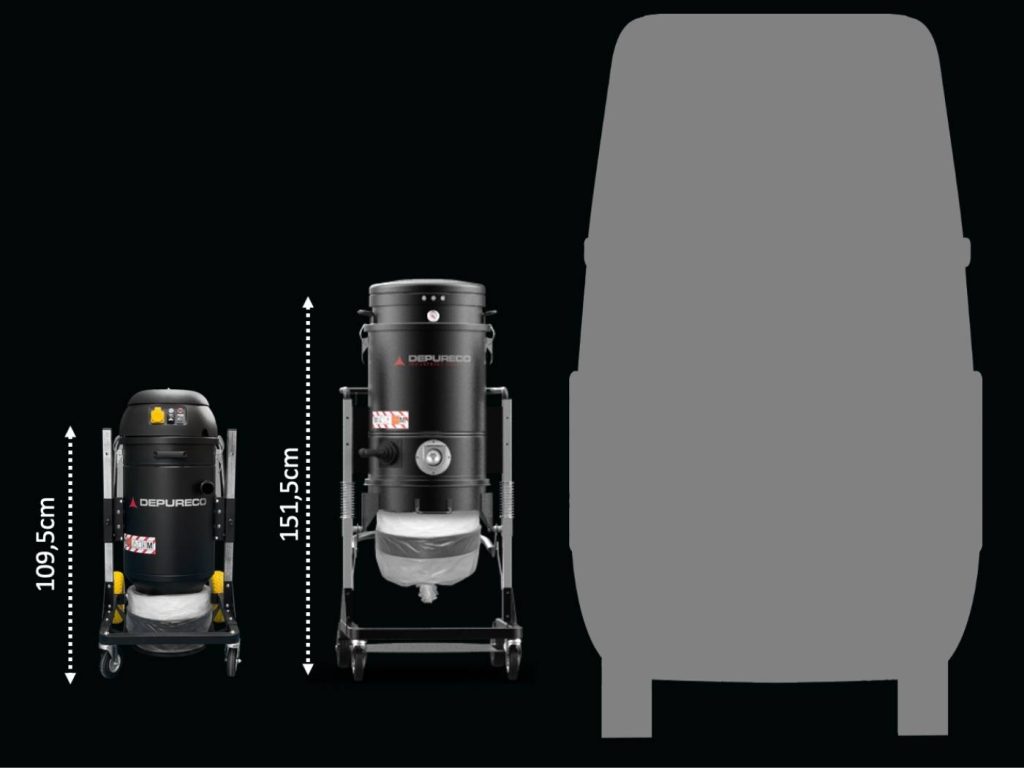

Portability and Maneuverability: If you require mobility or need to move the dust extractor frequently, consider a portable and lightweight model with handles or wheels for easy transportation. Ensure it has a long power cord and hose length to provide flexibility in reaching different areas.

Look for a dust extractor with sufficient airflow and suction power to effectively capture the dust generated by your specific equipment. Consider the size and power requirements of your tools and select an extractor that can handle the volume of dust produced.

Compact vacuums with excellent filtration capacity, designed to effectively capture and contain fine dust, which can pose a significant health hazard to workers and even damage machinery.

Consider the size of the dust collection container or bag. A larger capacity will allow for longer work sessions without the need for frequent emptying or changing of bags. However, bear in mind that larger capacities may also mean a bulkier and heavier unit.

If you require mobility or need to move the dust extractor frequently, consider a portable and lightweight model with handles or wheels for easy transportation. Ensure it has a long power cord and hose length to provide flexibility in reaching different areas.

When utilizing floor and surface preparation equipment, it is crucial to prioritize the selection of suitable dust extractors. These extractors play a vital role in establishing a safe and hygienic working environment. By carefully choosing the appropriate vacuum cleaner for your specific equipment, you can effectively mitigate potential risks and minimize the chances of environmental pollution. Whether you are employing hand tools, scarifiers, sanders, shot peening machines, or core drills, investing in reliable dust extractors is essential. This proactive measure not only safeguards the well-being of workers but also demonstrates a commitment to environmental protection, ensuring a harmonious balance between productivity and responsible practices.