INCREASE THE QUALITY OF THE FINAL PRODUCT AND REDUCE MACHINERY MAINTENANCE

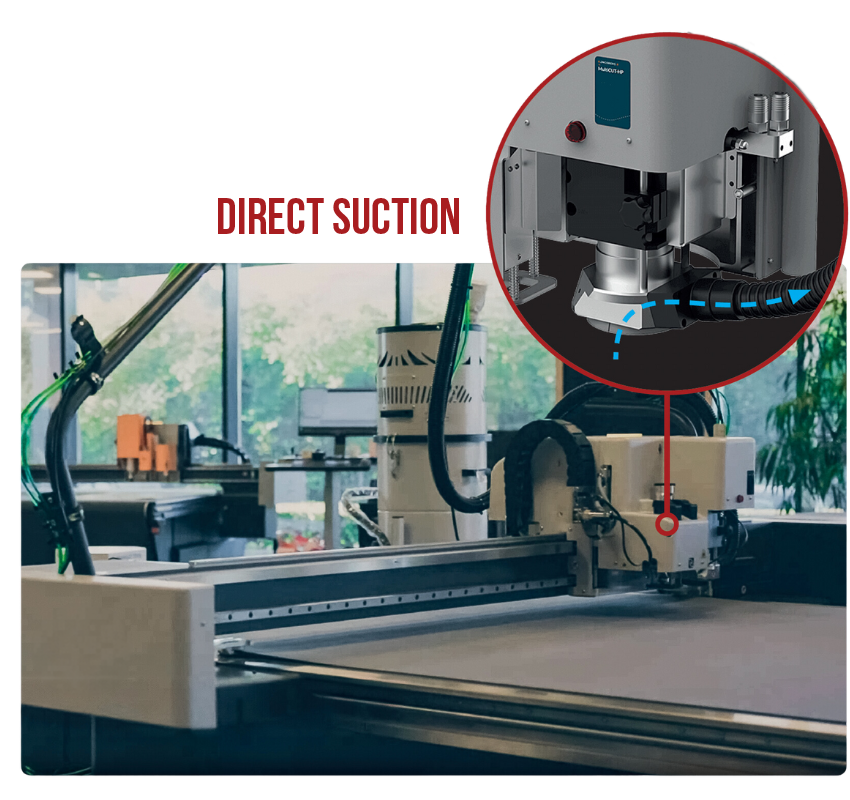

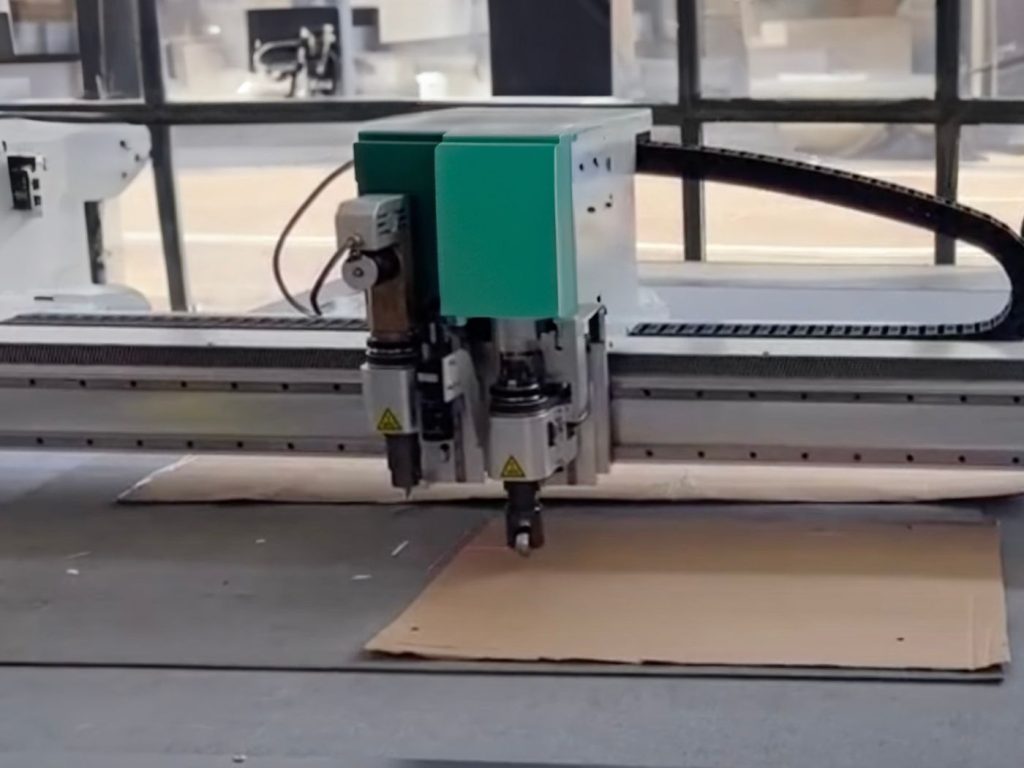

CNC pantographs are computer-controlled machines designed for the precise cutting of various materials. Depureco industrial vacuum cleaners efficiently remove dust, chips, and debris produced during the cutting of paper, cardboard, wood, flexible plastics, and composite materials with flatbed cutters and CNC routers.

When paired with digital cutting machinery, our industrial vacuum cleaners can capture particles of various sizes, from fine dust to larger fragments, right at the cutting source. This prevents their spread into the work environment, enhancing:

Industrial vacuum cleaners effectively remove dust, chips and debris generated during the cutting of materials such as paper, cardboard, plastics and composite materials. Installed on digital cutting machinery, they effectively capture particles of different sizes, from fine dust to coarse fragments, directly at the source of cutting. Vacuuming dust and cutting residues at the source prevents their dispersion into the work environment, improving the quality of the finished product and extending the service life of equipment.

With a comprehensive range of more than 180 vacuums and more than 50 years of experience, Depureco developed specific solutions for dealing with all kinds of fine, toxic, conductive or explosive dust. Analzying the specific parameters of the material being cutted, Depureco can define the safest and taiolored solution for your digital cutting machine.

We’ve engineered solutions for managing fine, toxic, conductive, or explosive dust. By assessing the specific characteristics of the material you’re cutting, we can recommend the ideal industrial vacuum cleaner for your digital cutting machine and your requirements. Here are some applications.

Cutting wood with CNC machinery generates a range of waste, from fine sawdust to larger chips and shavings. Efficiently removing these materials is crucial for maintaining precise cuts. Given that wood is a combustible material, implementing an explosion-proof industrial vacuum is vital. Our BL 45 Explosion Proof, featuring dual-stage filtration and comprehensive grounding, is the perfect solution to clean the working area. It is designed to manage significant amounts of wood debris continuously, offering safe suction of combustible dust.

Cutting Plexiglass generates large chips and flakes, making it crucial to simultaneously remove this debris to maintain cutting precision and prevent interference with the process or damage to the material’s surface. Our TX series vacuum cleaners are ideally suited for this task, as they are built to manage substantial volumes of chips and deliver exceptional suction power.

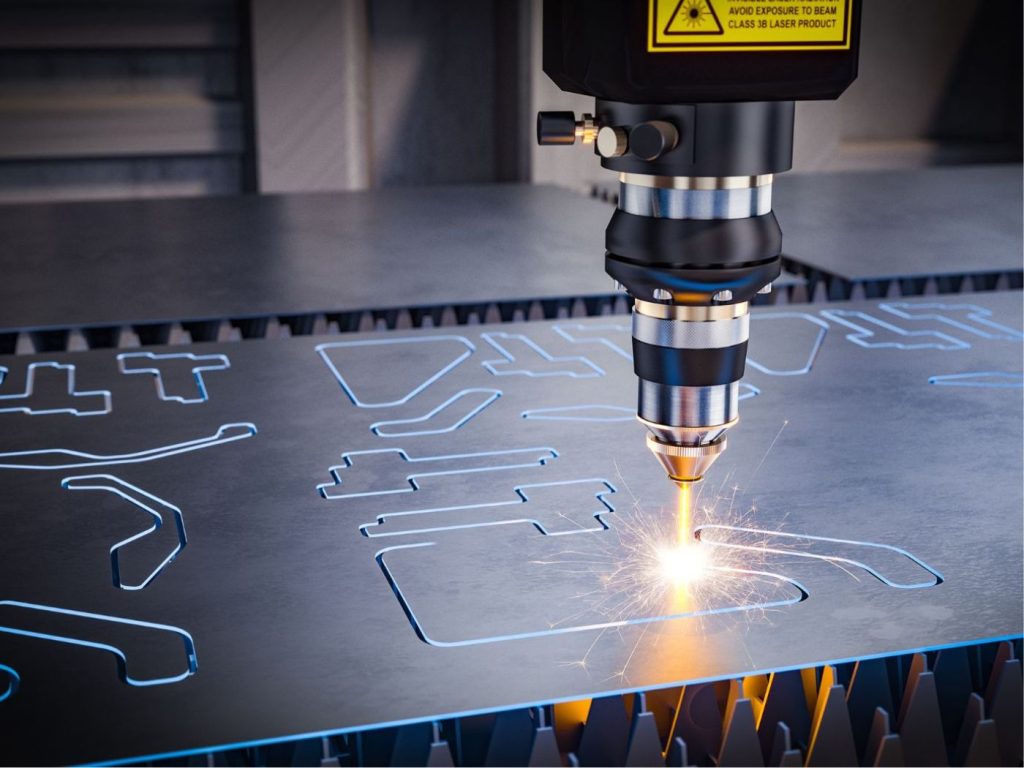

In metal laminate cutting operations with CNC pantographs, using an industrial vacuum cleaner is essential for achieving precise results. By efficiently removing chips and dust, the vacuum cleaner minimizes interference in the cutting process and aids in cooling the material, reducing the risk of thermal deformation. For managing potentially explosive metal dust, we provide NFPA compliant solutions with inerting baths to ensure optimal safety in environments where explosive dust may be present.

Cutting paper and cardboard produces extremely lightweight particles that can easily gather, with cellulose fibers often staying airborne. Similarly, cutting flexible plastics creates fine dust particles. For these materials, it is crucial to use an industrial dust extractor like our DF 22, which features an electric fan that generates powerful airflow to effectively capture and remove airborne dust.

We provide tailored suction solutions to meet a wide range of needs, including those specific to digital cutting applications. Our offerings include a variety of customizable options designed to enhance your operational efficiency. One notable solution is our suction tube lifting stand, which is engineered to keep the suction tube elevated above the table during machining. This feature ensures that the tube remains clear of the work area, preventing any potential interference with the cutting process and maintaining optimal suction performance.

By incorporating such specialized equipment, we help ensure that your digital cutting operations run smoothly and effectively, addressing specific challenges and optimizing the overall workflow. Whether you require standard solutions or bespoke configurations, we are committed to delivering the ideal setup for your unique requirements.

Why is using an industrial vacuum cleaner crucial for digital cutting tasks? Maintaining a clean workspace not only enhances cutting precision but also safeguards your equipment and promotes worker health. Our selection of industrial vacuum cleaners is engineered to maintain a neat work environment, ensuring top-notch performance and safety.

Contact us today to learn more about our industrial vacuums for digital cutting!