LIQUIDS

Robust Wet and Dry vacuum cleaners engineered to efficiently and safely handle various liquid substances encountered in industrial settings. With powerful suction capabilities and specialized liquid filtration systems, these vacuums can effectively extract liquids, sludge, and spills, ensuring a clean and hazard-free work environment. Choose from a range of industrial vacuums for liquids to tackle the toughest liquid cleaning challenges with ease and precision.

Industrial environments often encounter challenges related to the presence of liquids and spills, which can give rise to a range of problems. The risk of accidents significantly increases when floors become wet or slippery, posing a potential hazard for workers and increasing the likelihood of falls and injuries. Moreover, the presence of corrosive or conductive liquids can lead to damage in machinery and equipment. Electrical and mechanical components are particularly vulnerable, and the resulting malfunctions can cause costly downtime and disruptions to operations. In addition, spills have the potential to contaminate products being processed, compromising their quality and safety. This necessitates additional cleanup efforts and may even require the disposal of affected products, further impacting productivity and profitability. To effectively address these issues, it is essential to utilize specialized industrial vacuums designed specifically for liquids, equipped with features such as powerful suction, liquid filtration systems, and durable construction to mitigate risks, protect equipment, and maintain a clean and productive working environment.

When selecting an industrial vacuum for liquids, there are several key factors to consider. Firstly, evaluate the capacity and performance of the vacuum in terms of liquid handling. Look for a vacuum with a sufficient tank capacity to accommodate the volume of liquid you typically encounter in your industrial setting. Additionally, consider the vacuum’s suction power and airflow rate, as these determine its ability to effectively extract liquids and handle different viscosities.

Next, pay attention to the filtration system. Opt for a vacuum that includes specialized liquid filtration capabilities to prevent liquid particles from entering and damaging the motor or being released back into the air. Look for features like liquid-tight seals and filters designed to handle liquids without clogging.

Durability and construction are crucial aspects to consider. Industrial environments can be harsh and demanding, so choose a vacuum with a sturdy build, corrosion-resistant materials, and robust components that can withstand the rigors of liquid handling.

Consider the mobility and maneuverability of the vacuum. Look for features like sturdy wheels, handles, and a convenient hose length that allows you to easily move the vacuum around your facility, reaching all areas efficiently.

Let’s dive into the most important features to consider

By generating sufficient vacuum strength, the unit ensures that the vacuuming process is performed efficiently, allowing for quick and thorough cleaning or extraction tasks.

The collection capacity is a crucial factor in determining the ability to perform a task efficiently, as it ensures sufficient space to gather and store the materials being vacuumed or collected.

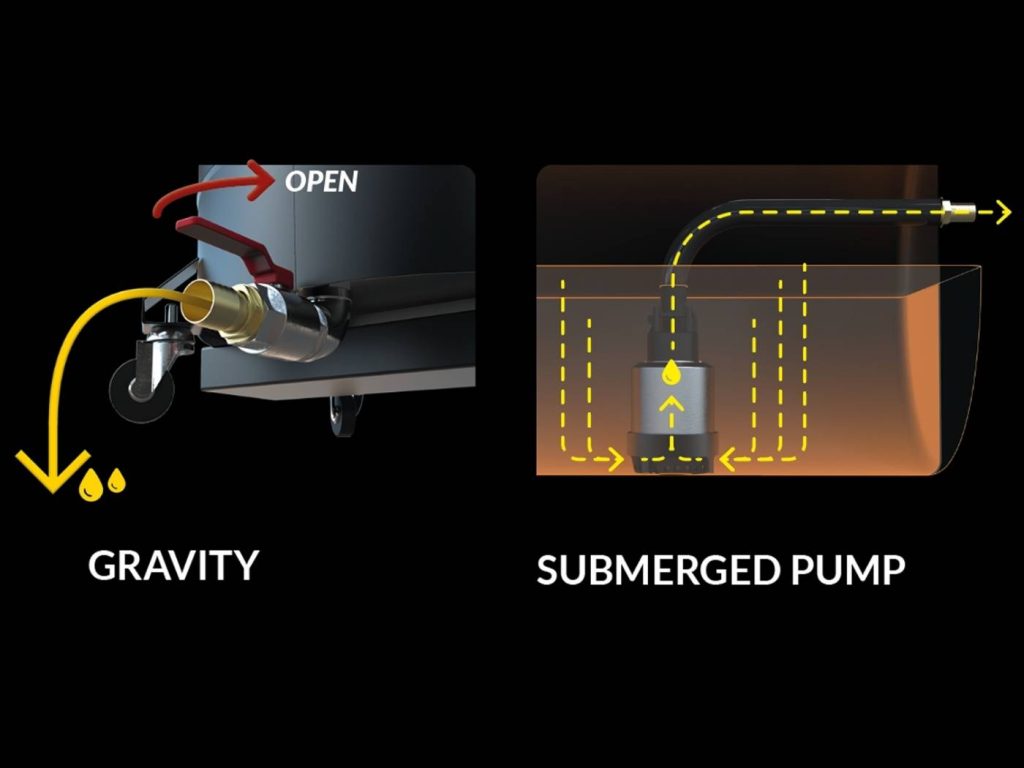

Effortless emptying of the liquid that has been vacuumed can be achieved through the use of a manual ball valve for discharge. In situations where larger volumes or heavy-duty tasks are involved, an alternative option is to install an immersed pump. This pump is designed to automatically and swiftly discharge the liquid once the predetermined level set on the overflow sensor is reached. This feature enables simultaneous suction and discharge of liquids, streamlining the process and enhancing overall efficiency.

Top-quality liquid vacuum cleaners are equipped with safety systems to address situations where the liquid level exceeds the maximum capacity limit. These advanced systems incorporate a floating device that is designed to automatically halt the suction process, effectively preventing the vacuum from overflowing. By promptly detecting the rising liquid level, the float switch ensures that the vacuum cleaner operates within safe limits and eliminates the risk of spills or damage caused by overfilling.

We will give you all the required information