3 - 3.5 HP | 480V 3~

2.325 in2

12 gal

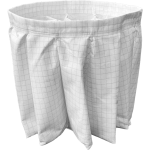

∣ It features a spacious filter chamber containing a high-surface polyester filter certified as M Class, ensuring efficient filtration down to 1 micron, even for very fine dust particles. Depending on the specific professional application, this industrial vacuum from Depureco’s three-phase range offers the flexibility to install different filters. Options include Teflon water-repellent filters, Nomex filters resistant to temperatures up to 482°F, and filters treated with PTFE for better binding and challenging dust conditions. Additionally, an H14 absolute filter can be optionally installed upon request. The TB industrial vacuum is designed with a sizable 12 gal detachable container, facilitating easy disposal of vacuumed materials. Disposable collection bags can also be utilized. For safe liquid vacuuming, a floating system can be provided in the container.

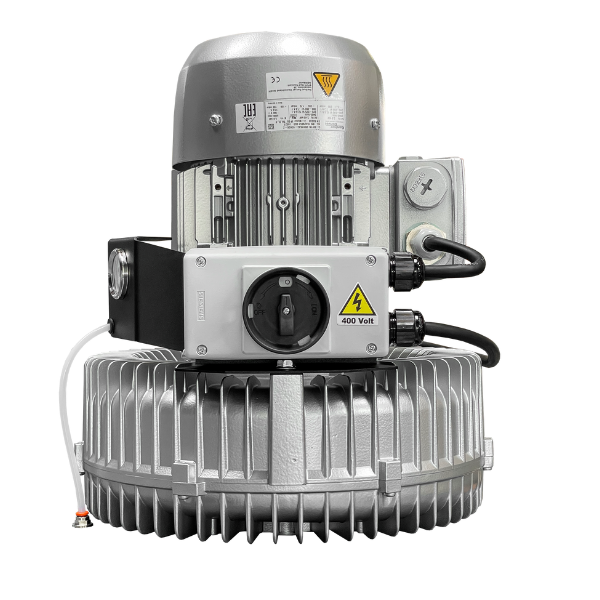

The suction mechanism of the vacuum utilizes a side channel blower with a direct connection between the motor and impeller. This side channel blower incorporates a safety valve, ensuring the utmost safety during continuous operation, without the need for maintenance.

The filtration process is effectively maintained by a polyester filter certified as M Class. Its unique star-shaped design enables the passage of air even when the filter becomes dirty. The filter's textile material adheres to M Class standards (BIA | En 60335-2-69), effectively trapping particles as small as 1 micron. This ensures the protection of both the motors and the operator in close proximity to the vacuum cleaner.

On one side of the filtration chamber there is an ergonomic manual shaker that permits to clean the filter easily and quickly, removing the dust and debris from the filter surface. Thanks to this smart cleaning system the operator can carry on working without changing or washing the filter.

The gathered material is stored within a robust steel container. Positioned at the rear of the vacuum cleaner, a metal handle allows for easy lowering of the bin. To facilitate effortless mobility, the container is equipped with four industrial wheels that pivot. Each wheel is securely positioned on a reinforced support, ensuring optimal stability even when the container is fully loaded and being moved.

H14 Absolute Filter (EN 1822) Glass fiber

Accessories basket

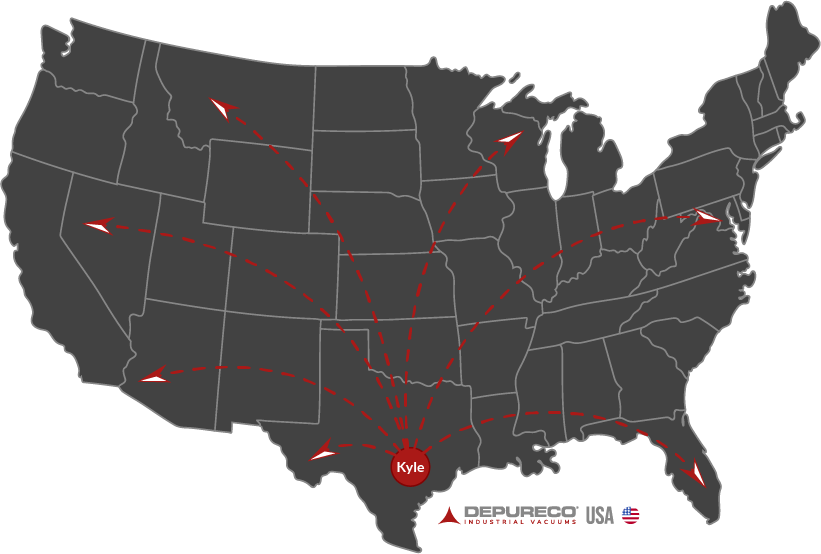

We will give you all the required information