up to 4.8 HP | 480V 3~

3,800 in2

26 gal

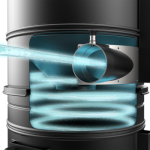

The Ecobull M industrial vacuum stands out as the most powerful option in its category. It features a 2.2 HP side channel turbine, making it ideal for continuous operation without requiring frequent maintenance. Its filter chamber boasts a generously sized polyester filter with a surface area of 3720.01 in2. This filter is certified as M Class, ensuring an efficient filtration efficiency of 1 micron, which is perfect for handling even the finest dust particles. The Depureco three-phase range of industrial vacuums offers the flexibility to install different filters depending on the specific professional application. Additional filter options include Teflon water-repellent filters, Nomex filters resistant to temperatures up to 482°F, and PTFE-treated filters for more challenging and adhesive dust types. Upon request, the unit can also be equipped with an H14 absolute filter. Practicality is enhanced by the Ecobull industrial vacuum’s large detachable container, available in sizes of 26 gal, equipped with wheels for easy material disposal. For added convenience, disposable collection bags can be utilized. To ensure safety during liquid suction, a floating system can be integrated into the container.

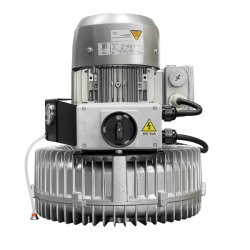

The suction unit of the vacuum utilizes a side channel blower with a direct coupling mechanism connecting the motor and impeller. This design ensures efficient and reliable operation. To prioritize safety, the side channel blower is equipped with a safety valve, enabling continuous work without the need for maintenance while maintaining a safe working environment. Additionally, the blower incorporates a metal silencer to minimize noise levels and provide a quieter working experience.

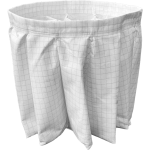

The filtration system is ensured by a polyester filter classified as M Class, which offers reliable performance. The unique star-shaped design of the filter allows for continuous airflow even when it becomes dirty. The filter fabric is specifically classified as M Class according to BIA | EN 60335-2-69 standards. This classification guarantees that particles as small as 1 micron are effectively trapped by the filter, protecting both the blower and the operator in the vicinity of the vacuum cleaner.

Located on a side of the filter chamber, there is a convenient and ergonomic manual shaker that allows the operator to effortlessly and swiftly clean the filter by removing any accumulated dust and debris from its surface. This intelligent cleaning system enables the operator to continue working without the need to replace or wash the filter, ensuring uninterrupted productivity.

The gathered material is stored within a robust steel container. Positioned at the rear of the vacuum cleaner is a metal handle that facilitates the lowering of the bin. The container is equipped with four industrial wheels, allowing for effortless mobility. Each wheel is securely positioned on a reinforced support to ensure optimal stability during movement, even when the container is fully loaded.

H14 Absolute Filter (EN 1822) Glass fiber

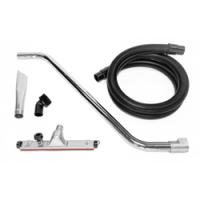

Accessories basket