3.5 HP | 480V 3~

2.325 in2

12 gal

The TB UP is a compact industrial vacuum that comes with a side-channel turbine located at the rear, enclosed in a sturdy metal casing. It comes with a standard vacuum breaker safety valve installed in the turbine. The filter chamber houses a spacious polyester filter with M Class certification, ensuring an efficient filtration of even the finest dust particles. Depending on the specific professional application, alternative filters can be installed in this particular model from the Depureco three-phase range. Options include Teflon water-repellent filters, Nomex filters resistant to temperatures up to 482°F, and filters treated with PTFE for enhanced binding of challenging dust. Additionally, an H14 absolute filter can be added upon request. The TB UP industrial vacuum is equipped with a sizable 12 detachable container that is conveniently mounted on wheels, making it easy for the operator to empty the collected material. Disposable collection bags can also be used for added convenience. Furthermore, a floating system can be incorporated into the container to safely vacuum liquids.

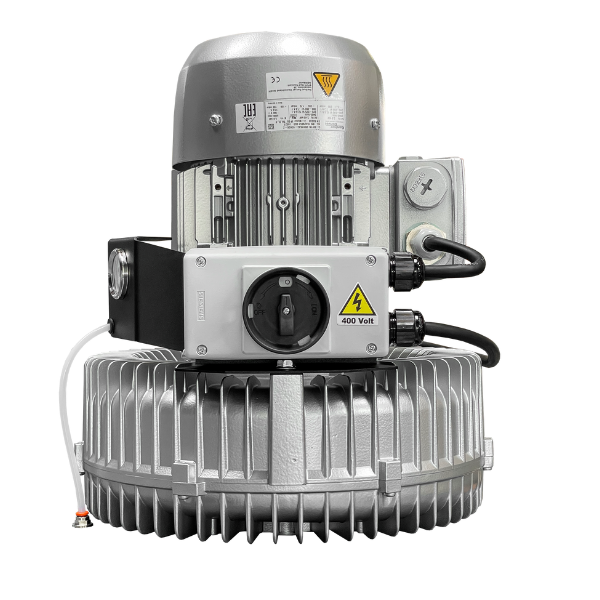

The suction system of the TB UP comprises a side channel blower that directly couples the motor and impeller. This side channel blower comes with a safety valve, ensuring safe and uninterrupted operation without the need for regular maintenance. Moreover, the blower is equipped with a metal silencer that effectively minimizes noise levels, enabling a quieter working environment.

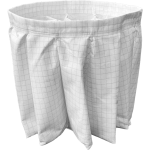

The filtration system is ensured by a polyester filter classified as M Class, providing reliable performance. The unique star shape of the filter allows continuous airflow, even when it becomes dirty. The fabric used in the filter conforms to the M Class (BIA | EN 60335-2-69) standards, effectively capturing particles up to 1 micron in size. This level of filtration offers protection for both the vacuum cleaner's motors and the operator, safeguarding against fine particles.

Located on the side of the filter chamber, there is a user-friendly manual shaker that allows the operator to effortlessly and rapidly clean the filter by removing dust and debris from its surface. This intelligent cleaning system enables the operator to continue working without the hassle of replacing or washing the filter.

The collected material is stored in a painted container that features a metal handle, allowing for easy detachment from the machine. With the assistance of its four swiveling wheels, the container can be effortlessly maneuvered and emptied.

H14 Absolute Filter (EN 1822) Glass fiber

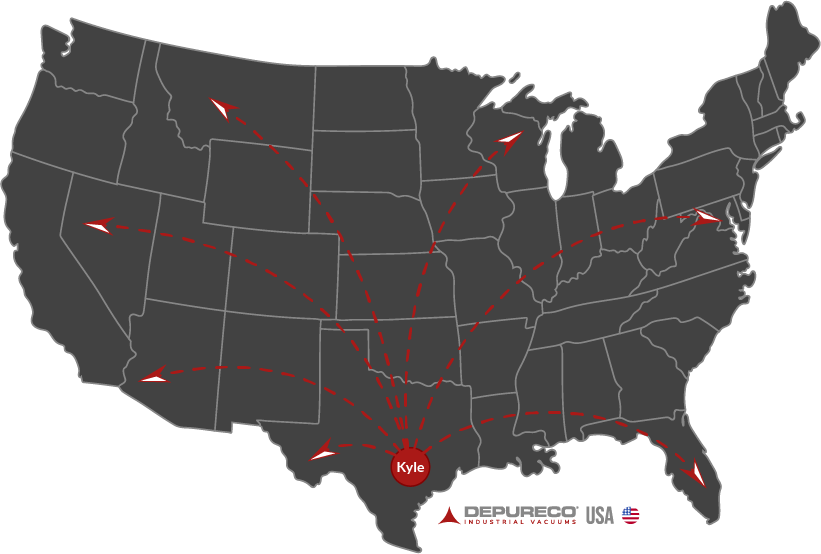

We will give you all the required information