3,720 in2

Up to 26 gal

The AC 100 Z22 is the most powerful intrinsically safe industrial vacuum cleaner in the Depureco range, designed for compressed air operation. With the utilization of a high-performance venturi tube, it achieves impressive levels of vacuum pressure. The AC 100 Z22 is capable of operating in diverse conditions, effectively handling powders, shavings, liquids, and challenging materials with the use of extended pipes. Inside the vacuum cleaner, there is a large surface filter made of antistatic polyester material, certified as M class with a filtration efficiency of 1 micron, ensuring the safe removal of electrostatically charged dust. For convenient maintenance, the industrial vacuum is equipped with a manual filter cleaning system, featuring a practical lever on the vacuum head that allows for easy and effective shaking of the filter. The vacuum cleaner is accompanied by a practical release container on wheels, facilitating the collection and disposal of vacuumed materials. The container is available in two options: 17 or 26 gallons of capacity, constructed from AISI 304 steel, and equipped with four sturdy swiveling wheels that enable effortless maneuverability, even when fully loaded.

The vacuum cleaner features a Venturi pipe that produces a powerful vacuum effect, functioning without the need for mechanical or electrical components.

The primary filter is constructed from durable antistatic polyester material. It contains a conductive net within the fabric to prevent the buildup of electrostatic charge. The unique star shape of the filter provides a generous surface area within a compact design, allowing for efficient airflow even when the filter becomes dirty. The filter material is certified as M class (BIA | EN 60335-2-69), ensuring that particles as small as 1 micron are effectively captured, safeguarding both the suction unit and the operator in the vicinity of the vacuum cleaner.

The tangential inlet is purposefully designed to facilitate the smooth entry of material into the bin. Within the chamber, a robust metal cyclone is securely welded, significantly reducing the speed at which the material enters and ensuring it directly descends into the bin. This effective mechanism provides optimal protection for the filter, greatly minimizing the risk of clogging.

The collected material is stored in a container made of AISI 304 stainless steel, ensuring durability and safety by minimizing the risk of sparks caused by electrostatic charge. The container is equipped with a sturdy metal handle that allows easy detachment from the machine. For effortless transportation and disposal of the collected material, the container is fitted with four robust pivoting wheels. Each wheel is reinforced to provide exceptional stability during handling, ensuring safe and secure movement.

H14 Absolute Filter (EN 1822) Glass fiber

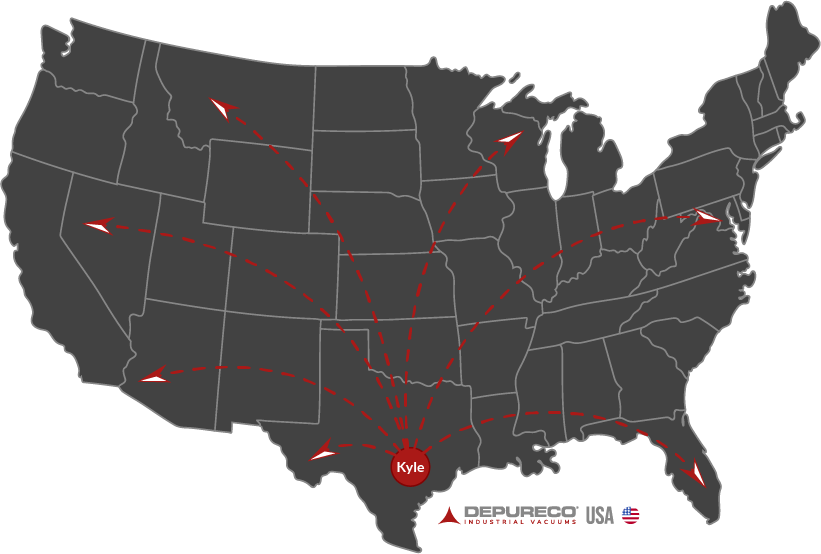

We will give you all the required information