4 HP | 120V 1~

132 gal

The RAM OIL 500T MP industrial vacuum cleaner boasts a sizable 132 gallons liquid tank, complemented by a separator basket with a capacity exceeding 18 liquid gallons. This machine is ideally suited for vacuuming, separating, and either reusing or disposing of oil mixed with swarf from tanks. As part of the Depureco oil and swarf range, the RAM OIL T500 MP is equipped with a standard 132/120 gal/sec pump for efficiently emptying filtered liquids. This capability enables operators to simultaneously vacuum liquids and sludge while discharging filtered emulsified liquids.

Power is generated by 3 single phase motors, ensuring exceptional vacuum speed. The hopper designed for collecting shavings is equipped with a metal basket, effectively separating solid particles from the liquid portion, and a 150-micron filter for enhanced filtration of swarf.

To simplify the disposal process and minimize the risk associated with manual lifting, the vacuum cleaner features a hopper tilting and discharge system that allows filtered residue to be discharged directly from the machine. This eliminates the need for manual container lifting. It has a pivoting suction inlet.

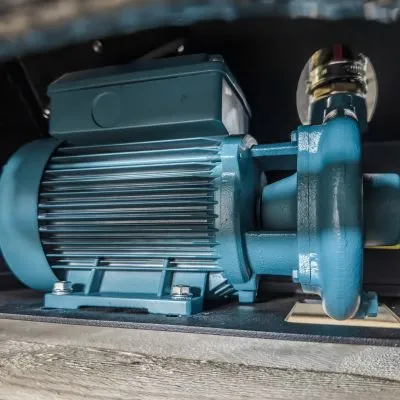

With an externally mounted pump, the tank can be rapidly emptied, leaving no residue behind. Since the pump is mounted externally, the full capacity of the tank can be utilized. The vacuum cleaner comes standard with the oil and chip accessory kit and includes a convenient accessory basket and two hose holder hooks.

For added convenience, two electrical level indicators are installed to automatically halt the vacuum flow when the maximum capacity is reached. This prevents overfilling and ensures efficient operation.

The RAM OIL T500 MP industrial vacuum cleaner is a versatile and high-performance solution, designed to handle oil and swarf effectively while offering user-friendly features and efficient liquid disposal capabilities.

Positioned above the vacuum's spacious tank is a tiltable hopper. Within the hopper, there is a metal mesh basket accompanied by a PPL filter. Together, they function as a highly effective sieve, ensuring the separation of any solid particles that may be present from the vacuumed liquid. This combination of the metal mesh basket and PPL filter guarantees optimal filtration and purification of the liquid during the vacuuming process.

The gathered liquid passes through a PPL filter with a 150µ efficiency, which enables the separation of even the tiniest solid particles. This process ensures that the filtered liquid becomes suitable for reuse. The filter is designed to be easily washed and reused. Additionally, there is an alternative disposable TNT filter with a 100µ efficiency that is also available.

To discharge the tank, the vacuum features an externally mounted pump, maximizing the container's full capacity and guaranteeing thorough emptying without any residue.

To always have everything at your fingertips"

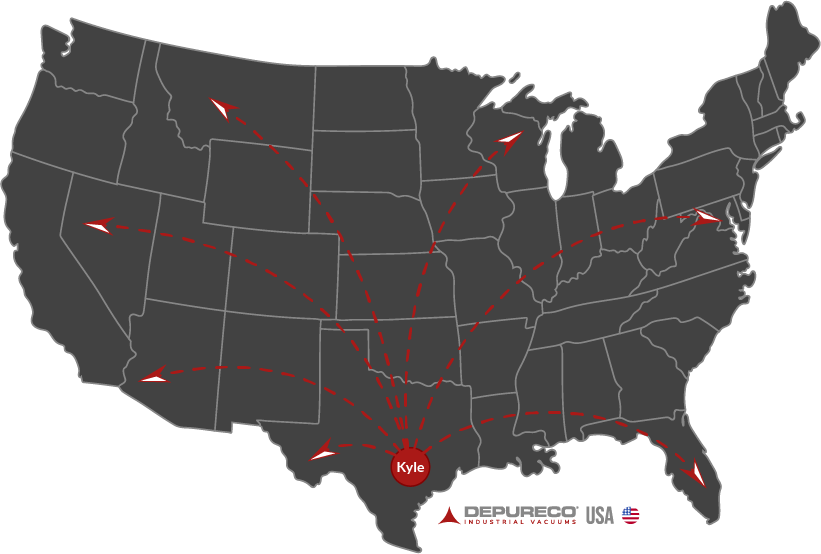

We will give you all the required information