4.8 HP | 480V 3∼

26 gal

The CLEAN OIL T industrial vacuum is specifically designed to effectively vacuum and separate oil and swarf from tanks, machine tool tables, and guides. It utilizes a side-channel turbine to generate suction, ensuring exceptional speed and power. With its compact size, the CLEAN OIL vacuum can be easily maneuvered even in narrow spaces, making it highly convenient.

The vacuum cleaner’s container is equipped with a metal basket to separate the solid particles from the liquid component. Additionally, it features a 150-micron nylon filter that enhances the filtration process, ensuring optimal effectiveness.

To prevent overflow, the vacuum cleaner is equipped with a floating level switch that automatically stops suction when the container reaches its maximum capacity (capable of holding 26 liquid gallons of emulsified oil). The container is equipped with a level indicator on its exterior, allowing the operator to monitor the liquid level inside the machine.

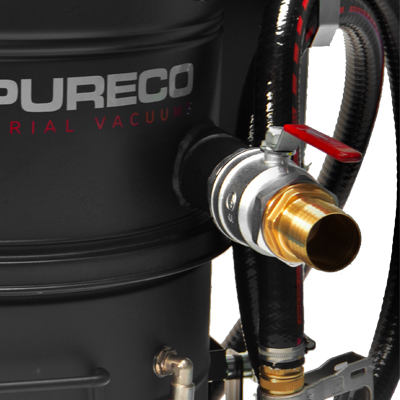

For discharge, the CLEAN OIL T vacuum utilizes a “reverse flow” system that allows gravity to facilitate the drainage process. This system ensures that all the vacuumed and filtered lubricant-coolant is replenished within the machine, contributing to its efficient operation.

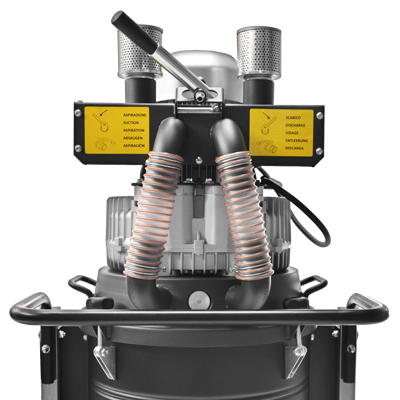

The suction unit utilizes a side channel blower with a direct coupling mechanism between the motor and impeller. This configuration ensures efficient and reliable operation. The side channel blower is equipped with a safety valve, which ensures uninterrupted and safe functioning, eliminating the need for maintenance. Additionally, the blower features a metal silencer that effectively reduces noise levels, promoting a quieter working environment.

The gathered liquid passes through a PPL filter with a 150µ efficiency, which enables the separation of even the tiniest solid particles. This process ensures that the filtered liquid becomes suitable for reuse. The filter is designed to be easily washed and reused. Additionally, there is an alternative disposable TNT filter with a 100µ efficiency that is also available.

A convenient lever, positioned at the rear of the vacuum cleaner, enables quick switching between vacuuming and discharging modes. The flow inversion system cleverly utilizes the exhaust air from the turbine, ensuring efficient and speedy operation.

The robust metal cyclone is equipped with a tangential inlet nozzle that effectively directs the material towards the collection bin. Within the collection bin, a float level indicator is strategically placed, which automatically interrupts the intake process by closing the cyclone when the bin reaches its full capacity. This mechanism halts the vacuuming operation, ensuring efficient and timely maintenance of the equipment.

We will give you all the required information