1.3 - 2.7 HP | 120V 1∼

5,500 in²

6 gal

The XM Torch industrial vacuum cleaner, offered by Depureco in their welding fumes range, provides an excellent solution for extracting fumes directly from the welding torch. This vacuum cleaner is specifically designed for this purpose. It features one or two powerful By-Pass motors and the control of this industrial vacuum cleaner is seamlessly integrated with the welding machine itself. To ensure safety and efficiency, a sophisticated sensor is strategically positioned on the vacuum cleaner to detect the flow of current in the ground cable, which is attached to a special clip. Depureco’s XM Torch industrial vacuum cleaner is equipped with a cellulose filter, ensuring the filtration of welding fumes while maintaining a high level of safety. Additionally, upon request, an H14 filter can be installed for even more advanced filtration capabilities.

The vacuum is created by a single By-Pass motor, and each motor is controlled by its own separate switch, providing the operator with the ability to regulate the suction power. The motors are housed within a robust casing, which incorporates an insulating sponge to effectively reduce noise levels.

The filtration is assured by a durable polyester filtering cartridge designed to provide a generous filter surface area (40,000 cm2) within a compact space. This allows for efficient air passage even when the filter becomes dirty. The filter is certified as M Class (BIA | EN 60335-2-69), ensuring its effectiveness in capturing particles as small as 1 micron. This not only protects the motors but also safeguards the operator from potentially harmful particles

The vacuum cleaner is fitted with a cutting-edge filter cleaning system called JetClean®, developed by Depureco. This innovative system takes advantage of the pressure differential between the vacuum cleaner's interior and exterior to create a powerful air jet. As this air jet passes through the cartridge, it effectively dislodges the dust particles from the surface of the filter. This process occurs swiftly and efficiently, allowing the filter to remain clean and fully functional during operations, without the need to interrupt the vacuuming process.

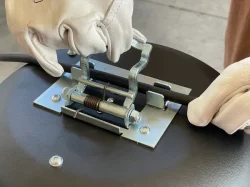

The machine incorporates a sensor located on one side, providing the operator with the ability to control the unit directly from the welding equipment. By passing the cable through the clip, a synchronized action is achieved. This means that when the welding process commences, the vacuum cleaner will simultaneously start operating.

H13 Absolute conical Filter (EN 1822)

H14 Absolute Filter (EN 1822) Glass fiber