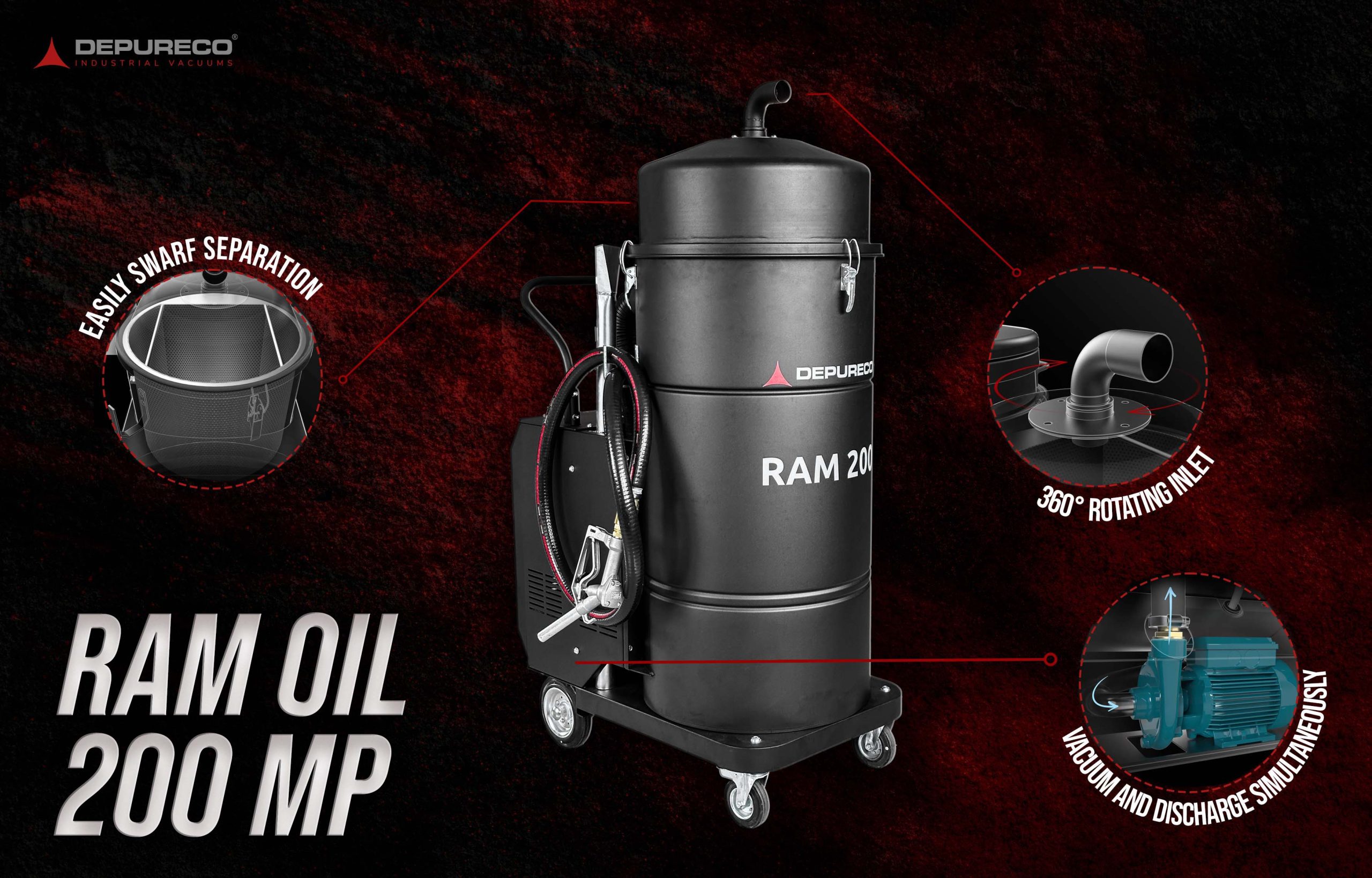

VACUUM AND DISCHARGE SIMULTANEOUSLY

ram 200 mp: the strongest ally in your cnc-shop

Does cleaning your CNC coolant tanks keep slowing you down?

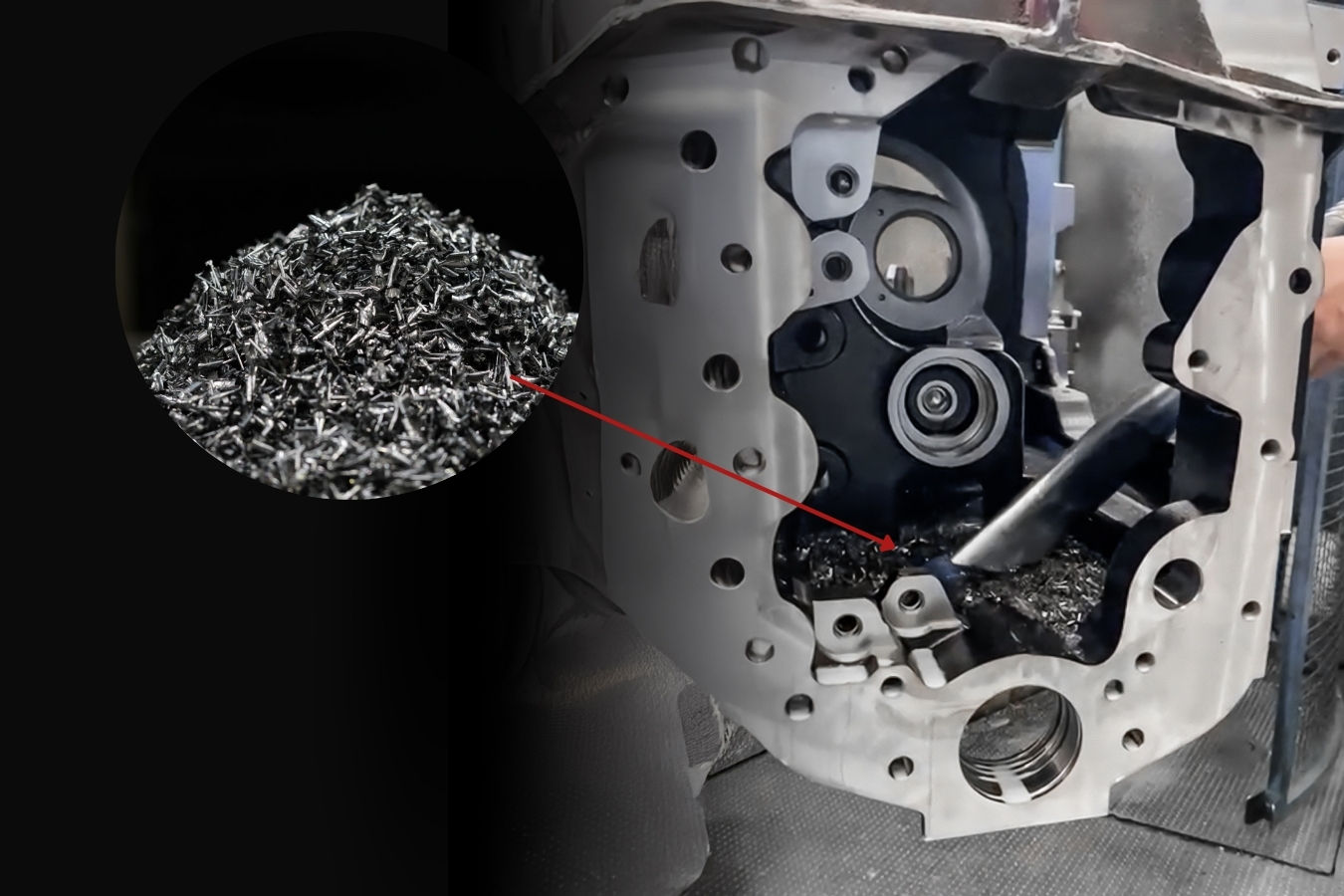

The new RAM OIL 200 MP turns CNC sump cleaning into a fast, repeatable task. It vacuums coolant and metal chips from the tank, collects the chips in a heavy-duty metal basket, filters the cutting oil down to 150 μm, and lets you put it back into circulation instead of throwing it away.

As the latest addition to Depureco’s sump vacuum range, it delivers high performance even in demanding CNC maintenance, thanks to:

Three powerful bypass motors for strong, consistent suction

A metal chip basket for efficient chip separation

An integrated pump that lets you vacuum and discharge filtered coolant at the same time

VACUUM, FILTER AND REUSE

For deep CNC tank cleaning

The power of the RAM OIL 200 MP helps cut maintenance time by delivering a truly deep clean of CNC tanks and removing even heavy, built-up cutting oil and sludge.

Filtered oil recovery

The heavy-duty metal chip basket separates solids from the cutting oil so it can be collected, recovered, and properly filtered before being quickly returned into circulation. When used together with the dedicated liquid filter, the oil can be cleaned and polished down to 100 µm.

Simultaneous vacuum and discharge

The RAM OIL 200 MP vacuums used oil and metal chips out of the CNC tank while at the same time pumping filtered oil back into the system. This simultaneous operation keeps CNC tank maintenance continuous and straightforward, without constant stops and restarts.

DISCOVER OUR FULL RANGE OF SUMP VACUUMS

Discover the full Depureco sump vacuum range: industrial vacuums engineered to handle CNC coolant tanks of different sizes, contamination levels, and maintenance routines, so you can easily choose the solution that best fits your shop’s needs.