SAFE AND CLEAN WORKSPACE, SUPERIOR FINAL PRODUCT QUALITY

Industrial vacuum systems play a crucial role in the manufacturing of electronic components such as microchips and printed circuit boards. These processes demand ultra-clean environments and exceptional precision. Even the tiniest dust particles or metal residues can compromise chip performance, leading to defects and lower production efficiency. Specialized vacuum solutions are essential for capturing semiconductor materials and ensuring contamination-free production.

These vacuums help maintain a controlled environment that meets industry standards by:

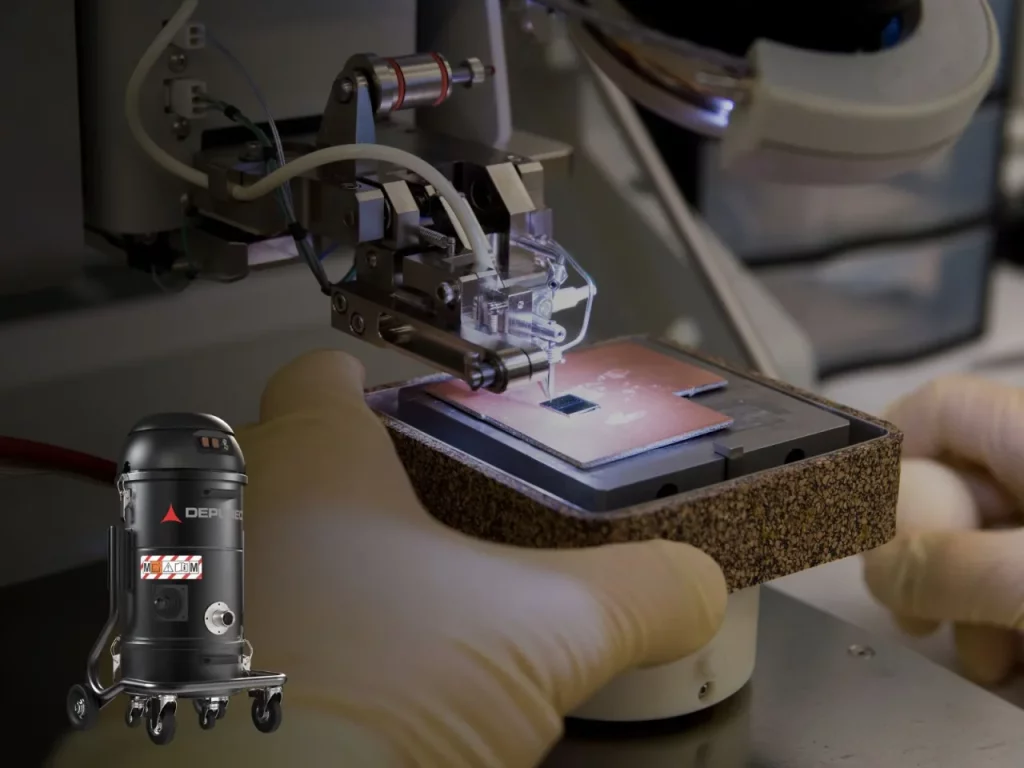

In manufacturing processes, the workbench is a key area where dust and debris accumulate, especially from cutting, etching, and assembling electronic components. To manage waste effectively and safely, it’s essential to use powerful, adaptable vacuum systems that can swiftly capture fine dust and byproducts. An efficient vacuum system not only maintains a clean work environment but also ensures compliance with safety regulations, minimizing downtime and eliminating the need for manual cleaning.

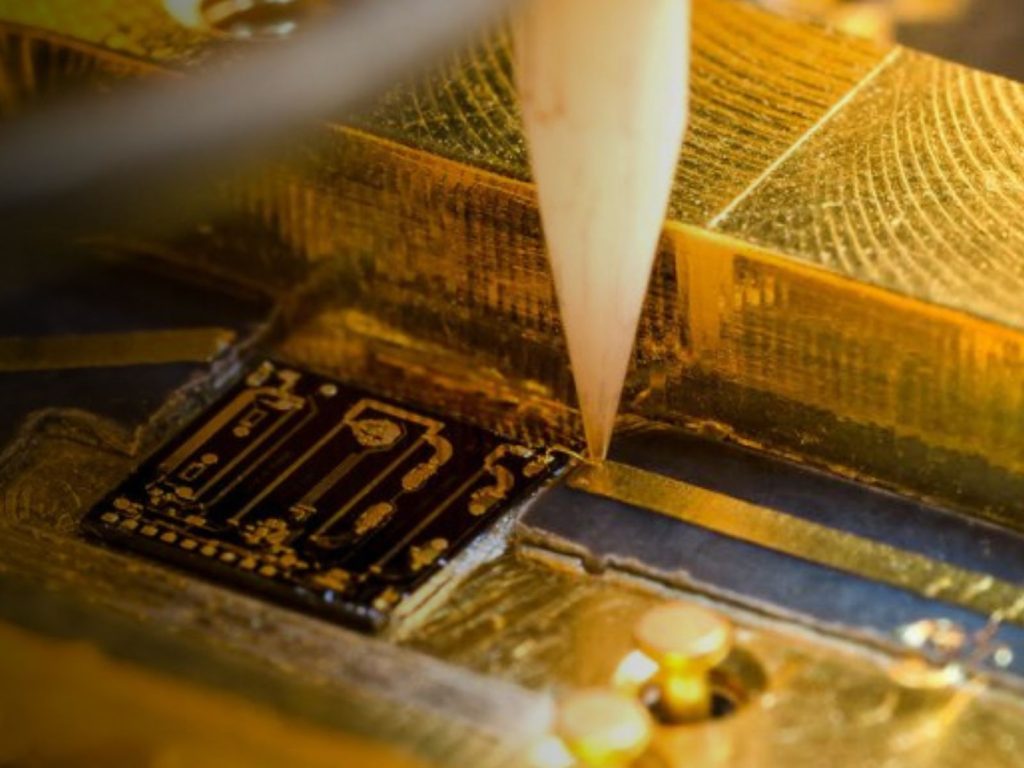

Precious metals like gold and copper play a crucial role in ensuring the performance and reliability of electronic chips, especially during processes like wire bonding and other key production stages. However, these materials can be lost as dust or particles during manufacturing, leading to both economic losses and environmental concerns. We provide tailored vacuum solutions designed to efficiently recover these valuable metals, reducing waste and enhancing the sustainability of the production process.

Depureco offers a variety of industrial vacuum cleaners designed for semiconductor materials used in chip and printed circuit board production, including models with HEPA filtration.