HEPA filtration plays a crucial role in numerous industrial cleaning operations. Vacuums equipped with HEPA filters are indispensable across various applications. In specific scenarios, HEPA filters can guarantee the safety of production staff.

hepa filters in industrial vacuum

The term “HEPA” stands for “High-Efficiency Particulate Air [Filter]”, denoting a specialized filter designed to capture airborne particles.

ISO standards categorize filters based on their ability to remove 0.3 µm particles. HEPA certification requires a filter to demonstrate efficiency ranging between 99.97% and 99.995%. There are two types of HEPA filters:

- H13: Efficiency of at least 99.97%

- H14: Efficiency of at least 99.995%

Every Depureco Industrial Vacuum is adaptable to incorporate a HEPA H14-certified filter in addition to its primary filter.

With HEPA H14-certified industrial filters, you can effectively vacuum extremely fine and hazardous dust particles.

hazardous dust that can be captured by HEPA H14 filters

HEPA H14 filters ensure a safe work environment by effectively trapping harmful dust particles. Below are examples illustrating the different materials these filters can capture:

- Cement powders and building material

- Powders in the cosmetic industry

- Polishing powders

- Powders from the pharmaceutical industry

- Asbestos dust

- Food powders such as cocoa and milk powder

- Silica dust

- Powders of composite materials such as carbon fiber and glass fiber

- Chemical powders

HEPA filters: how do they work?

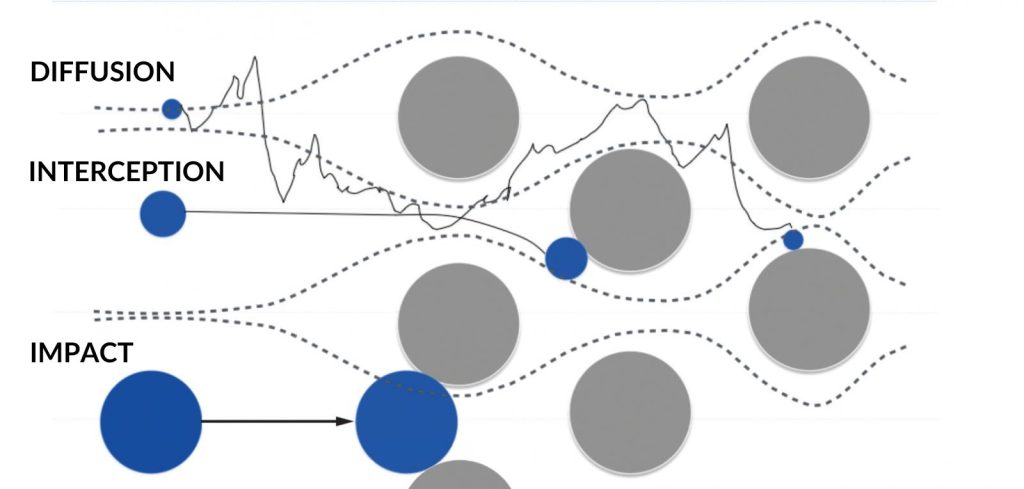

Particle filtration occurs primarily in three different ways, depending on the type of particle:

- IMPACT – Large Particle: These particles are too large to pass through the openings in the filter medium and are thus retained on the outer surface of the material.

- INTERCEPTION – Medium Size: Air carries particles through a complex fiber structure, where the particles collide with the surface of these fibers and become trapped.

- DIFFUSION – Small Size: Diffusion affects the smallest particles, causing them to collide with each other and other particles. Their direction changes rapidly, leading to a decrease in velocity. Eventually, this movement causes the particles to collide with the fibers of the HEPA H14 filter medium.

Feel free to contact a Depureco specialist for further details on the optimal filtration solution tailored to your unique application.