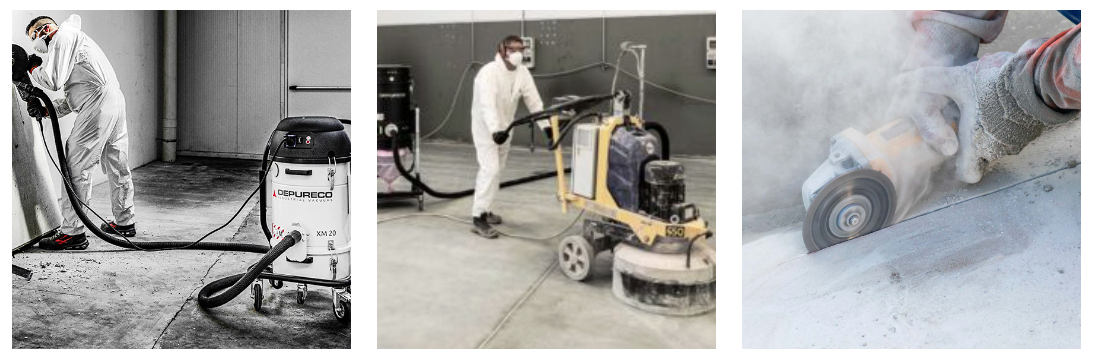

Importance of Dust Extraction when Handling Silica Dust

Handling hazardous materials such as silica dust demands top-notch safety measures. Our HEPA DUST EXTRACTOR XM 35 JC Longopac is your shield against these dangers. Silica dust, notorious for its health hazards, necessitates a robust solution, and our extractor ensures a clean and safe environment.

Watch it in action!

Dual Filtration System for Enhanced Safety

Our extractor boasts a dual filtration system to safeguard against harmful particles.

- The Conical Polyester Cartridge Filter M CLASS in PTFE, which acts as the primary filter;

- Standard H 14 HEPA Filter 3410 in².

Class M filtration refers to a highly efficient filtration level specifically designed to capture very small and hazardous particles in the workplace environment.

In the context of industrial vacuums, filtration classifications adhere to standard norms that identify different levels of efficiency. Class M filtration is notably effective in trapping tiny particles such as fine dust present in the air during industrial processing.

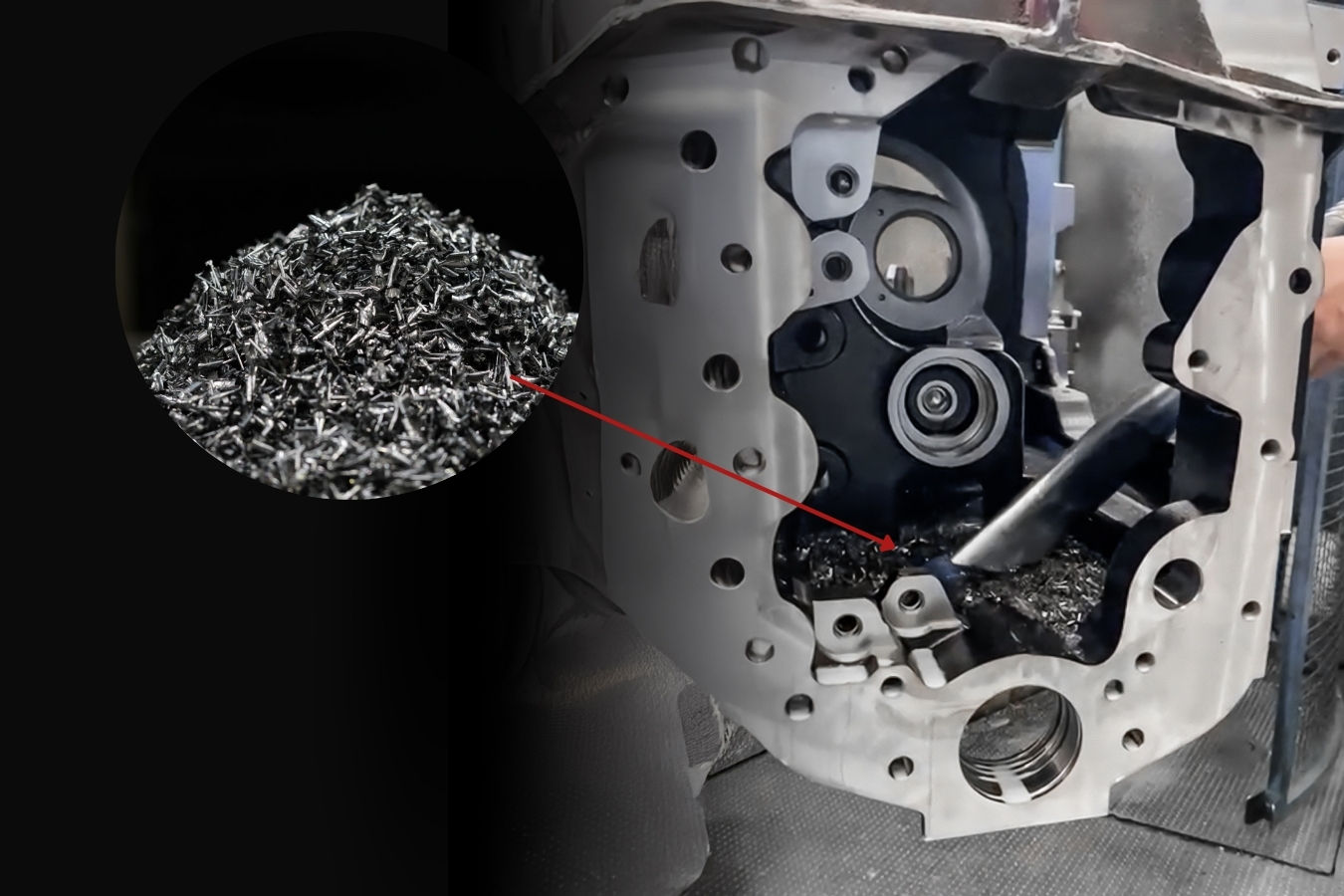

The effectiveness of Class M filtration is attributed to high-quality filter materials that capture particles up to a certain size, minimizing the release of harmful elements into the surrounding environment. This level of filtration is crucial for maintaining a safe and healthy workspace, particularly in industries where fine dust or hazardous particles are generated during processes like metalworking or additive manufacturing.

On the other hand, High Efficiency Particulate Air (HEPA) is a standard of filtration renowned for its exceptional ability to trap extremely small particles from the air. HEPA filters are designed to capture 99.97% of particles that are 0.3 microns or larger in size.

The HEPA standard is widely recognized and used across various industries, including healthcare, manufacturing, and environmental safety. It’s particularly crucial in environments where air quality is of utmost importance, such as hospitals, cleanrooms, and spaces where contaminants need to be significantly reduced.

These filters consist of a dense arrangement of fibers that form a mat-like structure. Air passes through this matrix, and particles are captured through mechanisms like diffusion, interception, and inertial impaction. The efficiency of HEPA filters makes them ideal for removing allergens, dust, pollen, mold spores, bacteria, and even some viruses from the air.

In industrial vacuum cleaners, HEPA filtration is an essential feature, especially when dealing with fine or hazardous particles. It ensures that the air expelled from the vacuum is significantly cleaner and free from the vast majority of particles that have been vacuumed up.

HEPA filters are graded according to their efficiency, with H10 to H14 being common grades. These filters play a pivotal role in enhancing air quality and creating a safer, healthier environment in various settings.

In our Industrial vacuum XM 35 JC LP H14, this dual setup ensures comprehensive filtration, trapping even the finest particles.

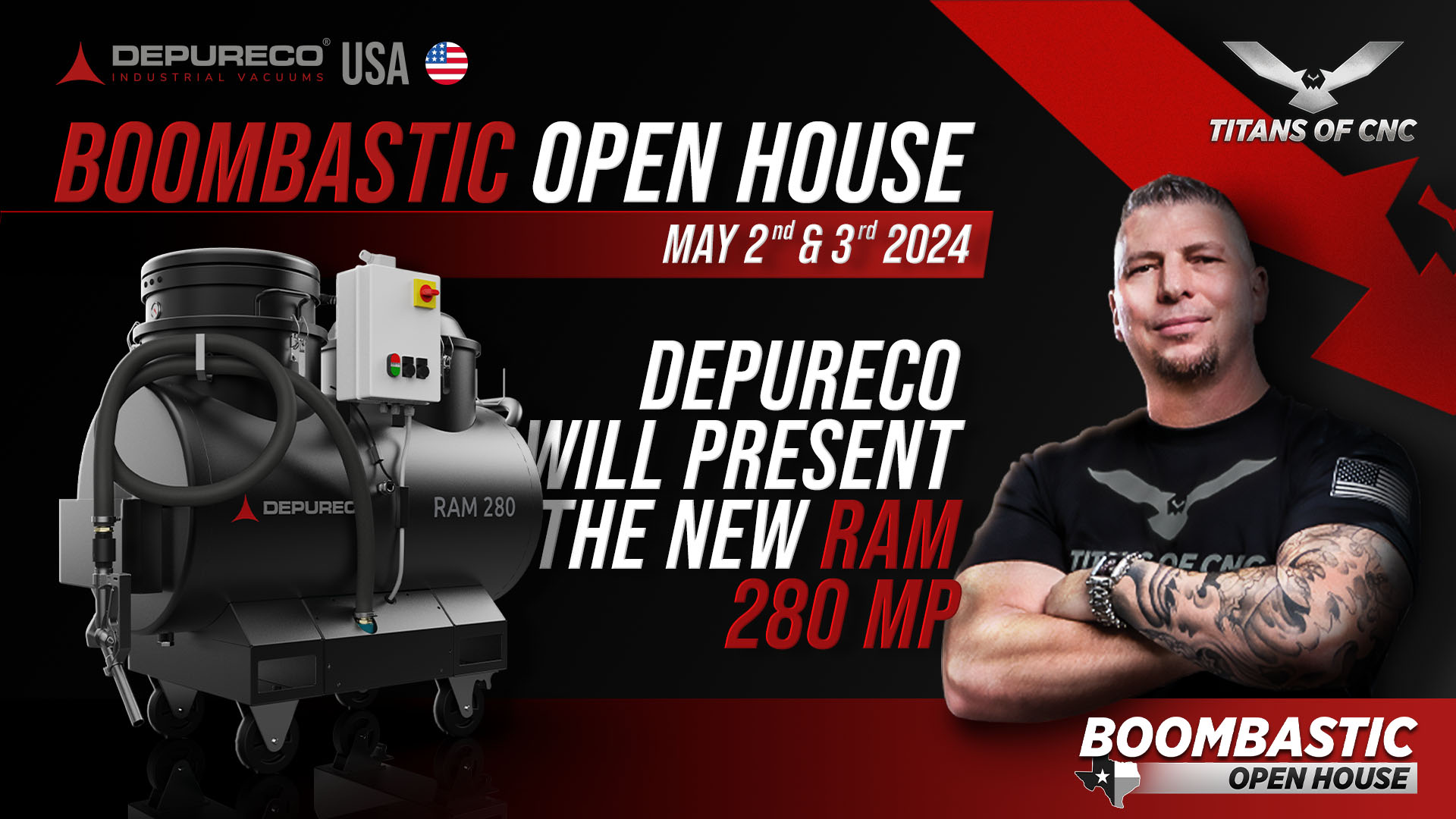

Superior Performance: Hepa Vacuum with Dual Bypass Motors

Equipped with two powerful bypass motors, our HEPA DUST EXTRACTOR XM 35 offers unparalleled performance. These motors ensure high efficiency, guaranteeing a maximum vacuum power of 98 inH2O and a maximum airflow of 224 CFM, providing optimal suction for your workspace.

The significance of the maximum vacuum power being at 98 inH2O lies in its direct correlation with the extractor’s effectiveness in suction and debris removal. This specific measurement represents the extractor’s remarkable ability to create a strong negative pressure, crucial for pulling in and retaining fine particles, debris, and contaminants from surfaces. A vacuum power of 98 inH2O signifies an exceptional force capable of handling various materials and particles within an industrial setting. This level of power ensures that even the most stubborn or deeply embedded debris can be efficiently lifted, providing a comprehensive cleaning process. Ultimately, this high vacuum power translates into enhanced efficiency and effectiveness, ensuring a cleaner, safer, and healthier workspace.

The maximum airflow of 224 CFM holds immense importance in the functionality of the extractor, primarily contributing to its exceptional cleaning capabilities. This measurement signifies the volume of air the extractor can move in a minute, crucial for swiftly and effectively lifting and transporting particles and debris from various surfaces. A high airflow rate of 224 CFM ensures rapid and thorough cleaning, as it facilitates the quick suction of particles, preventing them from settling back onto cleaned surfaces. This substantial airflow guarantees an efficient and comprehensive cleaning process, maintaining optimal cleanliness in the workspace and significantly reducing the time required for effective vacuuming. Ultimately, this robust airflow enhances the extractor’s performance, ensuring a more productive and efficient cleaning experience.