Automatic Vacuum Cleaning System for Multi-deck Ovens: our Case Study

Industrial bakeries face strict quality standards to ensure their products meet excellence. Maintaining cleanliness is mandatory in food processing. Employing an industrial vacuum cleaner for ovens enables the simple removal of crumbs, baking residues, and burnt flour, safeguarding against contamination and preserving product quality.

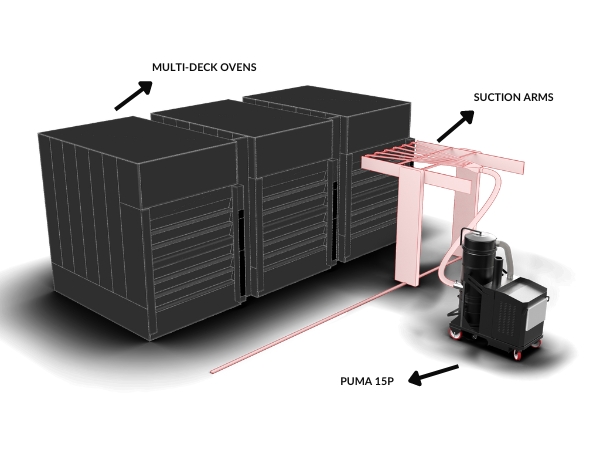

Multi-deck ovens are a staple in industrial bakeries, prized for their versatility in simultaneous production. However, their extensive size poses challenges during cleaning, particularly between batches, making it a time-consuming and intricate task.

Benefits of implementing a vacuum system for multi-deck ovens

Advantages of maintaining cleanliness in an industrial bakery, ensuring absence of warm debris, fragments, and scorched flour:

- Improved product excellence;

- Adherence to sanitation guidelines;

- Efficiency in cleaning procedures.

By acquiring an automated industrial vacuum setup for bakeries, cleaning tasks are notably accelerated. Furthermore, there is no requirement for hiring personnel to vacuum the ovens between successive baking sessions.

Our Installation

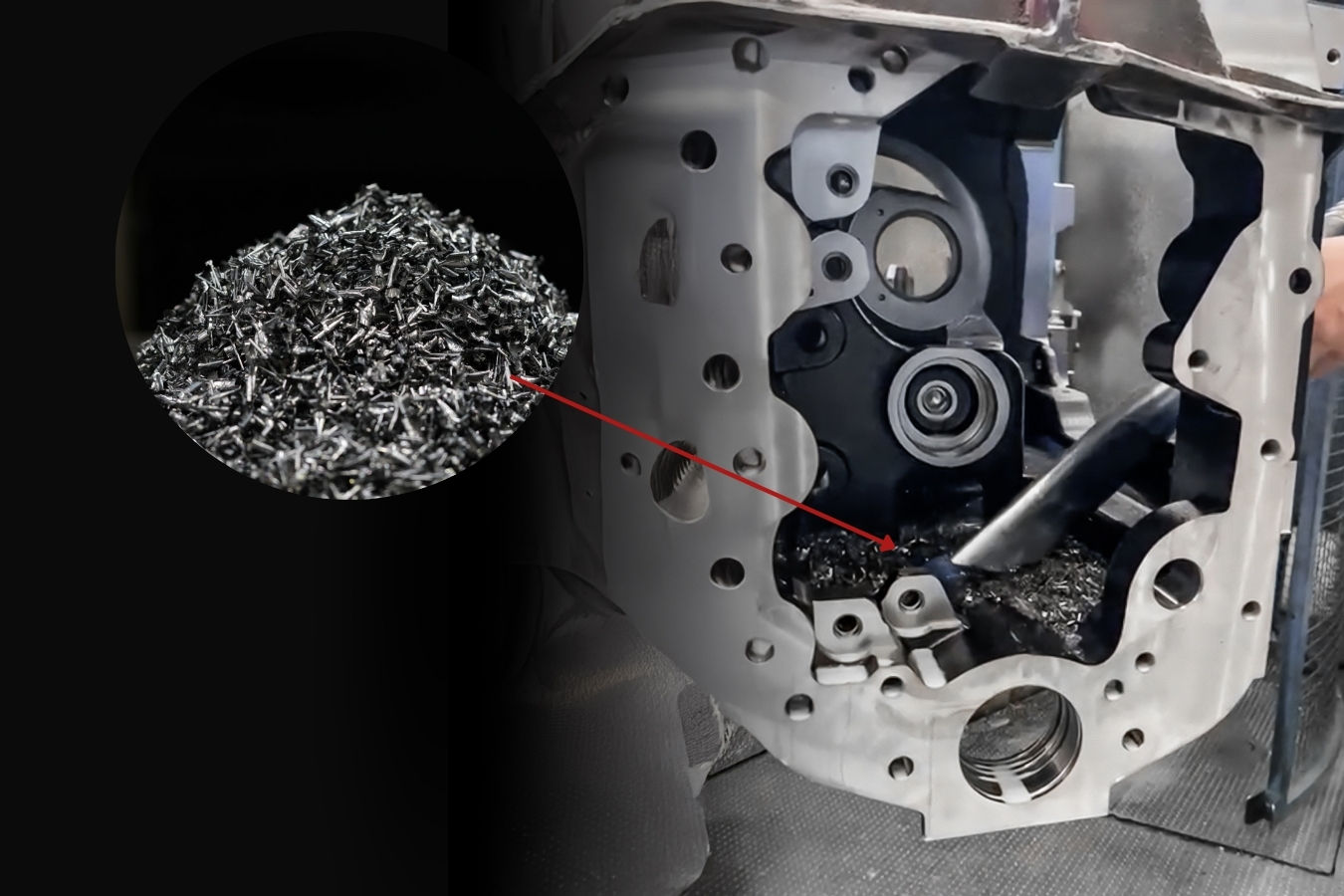

Our customer needed to remove baking remnants and burnt flour from their multi-tier oven. To enhance operational efficiency, using an automated vacuum device resilient to elevated temperatures became imperative, eliminating the need for manual cleaning by operators.

Features

- 1 vacuum unit;

- 6 suction arms with brushes, linked to a unified vacuum tube for effortless access to all oven corners;

- Metal framework supporting the suction arms; Installed tiltable bin kit for convenient discharge of the 41 gal container.

The metal structure facilitates the lifting of the 6 arms for entry into each oven chamber. Their back-and-forth motion ensures thorough cleaning.

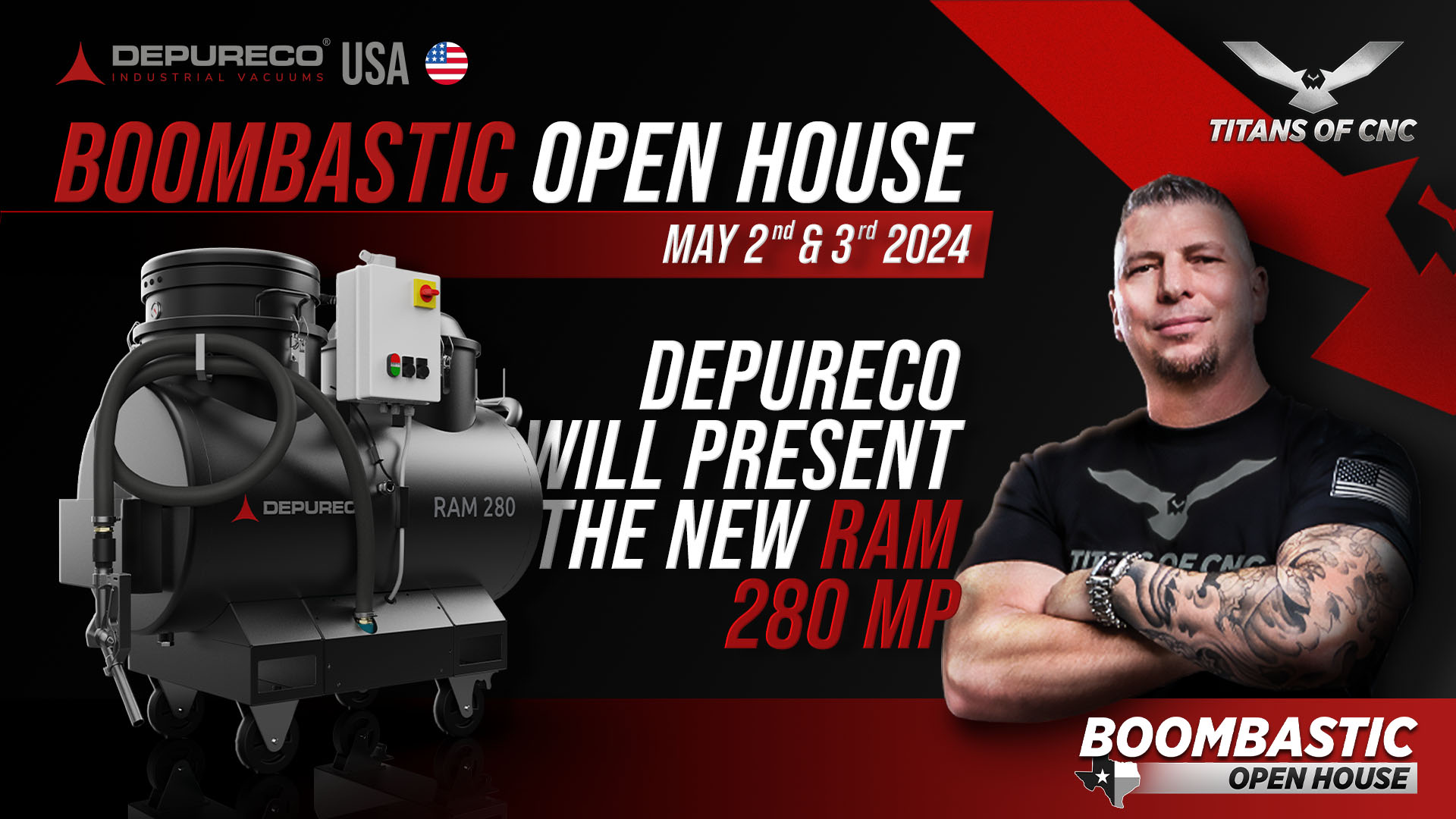

Vacuum Unit: Puma 15 P

The chosen central vacuum unit for this installation is the Depureco PUMA 15 P. This unit offers the following features:

- Powerful 17.5 HP side channel blower, specifically treated for high-temperature applications.

- NOMEX Filter, up to 482° F.

- Automatic cleaning system PSC (compressed air required).

- 41-gal collection bin with a metal handle and 4 pivoting wheels. Tiltable bin kit is included in this installation.

- Remote control of the unit.

- Rotary level sensory, that stops suction when the container reaches its maximum capacity.