1.5 HP | 120V 1~

5,425 in²

12 gal

The BL AM (Additive Manufacturing) is an industrial vacuum cleaner specifically crafted to remove conductive metal dust. This vacuum cleaner features a powerfull single-phase brushless motor, delivering exceptional performance and maximum safety, even in potentially explosive environments.

To collect dangerous particles, this product incorporates an advanced explosion-proof system: the vacuumed conductive metal powder is directly immersed in a bath of inert liquid within the container. The motor is safeguarded by a large-surface H13 class antistatic conical filter. Additional filtration inside the container ensures the highest levels of safety, even when dealing with potentially explosive dust. Inside the inerting container, there is a metal grid filter to capture any sparks and a nylon filter that separates the sucked metal dust from the inert liquid, allowing for recovery and reuse. A patented quick-connect system enables the container to be detached and reattached easily, no tools are required. An overpressure valve permits gas to escape if there is a reaction between the powder and the liquid used.

The exhausted liquid can be discharged by gravity through a convenient tap at the bottom of the container. The container is made of AISI 304 stainless steel and features a handy inspection window on the front to monitor the liquid level inside.

With our BL AM, vacuuming conductive metal dust has never been simpler and safer!

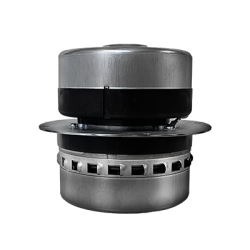

The vacuum unit features a robust brushless motor, perfect for continuous operation. It includes two filters on the vacuum cleaner head: one to shield the motor and another positioned at the air outlet. The discharged air is completely free of carbon.

Filtration is ensured by a durable polyester cartridge filter. This cartridge is designed to maintain a large filter surface area within a compact space, allowing air to flow through even when the filter is dirty. The filter is certified class H (BIA | EN 60335-2-69), protecting both the motors and the operator.

The container is IIIC-certified and features a conductive metal powder inerting oil bath system. It includes various filtration levels to ensure maximum safety across all areas of application.

Installed on the vacuum chamber, the hydrogen vent valve enhances operator safety by releasing any gases that may accumulate inside the vacuum cleaner.