1.5 HP | 120V 1∼

2,325 in2

11 gal

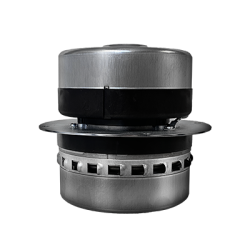

Industrial vacuum cleaners that are ATEX certified are renowned for their safety in hazardous environments. One such model is the BL 45 Z22, a compact vacuum cleaner belonging to Depureco’s ATEX-certified range. It utilizes a high-performance Brushless motor, delivering both powerful suction and silent operation. The BL 45 industrial vacuum cleaner features a large surface filter with an impressive area of 5,4 certified as class M for exceptional filtration efficiency, capturing particles as small as 1 micron. Upon request, an optional absolute filter H14 can be installed to enable the removal of even the finest dust particles. The filter chamber is constructed from standard AISI 304 stainless steel, ensuring durability and reliability. Cleaning the filter is a breeze with the inclusion of a convenient, robust, and highly effective manual shaker. All collected material is deposited in a 12 gallons capacity container made of AISI 304 stainless steel, further enhancing its durability and ease of maintenance.

The suction mechanism of this vacuum cleaner utilizes a high-powered brushless motor, designed to operate continuously. The motor head incorporates two filters: one that safeguards the motor itself and another placed on the air outlet. Notably, the expelled air is completely free of carbon emissions.

The primary filter is constructed from robust and antistatic polyester material. Within the fabric, a conductive net is integrated to prevent the occurrence of electrostatic charge. The star-shaped design ensures a substantial filter surface area within a compact space, allowing for continuous airflow even when the filter becomes dirty. The filter fabric is certified as M class (BIA | EN 60335-2 -69), signifying its ability to capture particles up to 1 micron in size. This level of filtration provides protection for both the motor and the operator in the vicinity of the vacuum cleaner.

The collected material is stored in a container made of AISI 304 stainless steel, which features a metal handle allowing for detachment from the machine. This design consideration aims to prevent the occurrence of sparks resulting from electrostatic charge. Additionally, the container is equipped with four robust pivoting wheels, enabling effortless mobility for the purpose of disposing of the collected material.

Located on one side of the filter chamber, an ergonomic manual shaker provides a convenient means for the operator to swiftly and effectively clean the filter. By utilizing this intelligent cleaning system, the operator can easily remove dust and debris from the filter's surface, ensuring continued functionality without the need to replace or wash the filter. This enables uninterrupted work efficiency for the operator.

H14 Absolute Filter (EN 1822) Glass fiber

Accessories basket