Ensuring a Dust-Free and Healthy Work Environment

Aluminum processing, like cutting profiles or frames, produces waste in swarf and residues. If this waste isn’t properly managed or disposed of, it can cause machine malfunctions and slow down production.

That’s why it is essential to equip machines like cutting saws and CNCs with continuous extraction systems, to prevent buildup during cutting operations.

Our dust collectors can be easily integrated with cutting machines and are designed to vacuum chips and residues produced during aluminum processing directly at the source. They provide a strong suction power and optimal airflow.

Benefits of maintaining a clean work environment free of aluminum residues:

Reduced costs and downtime for machine maintenance compared to traditional cleaning methods;

Enhanced quality of the final product;

Clean and safe work environment.

Our solutions are designed to fit different machines, ensuring effective waste management.

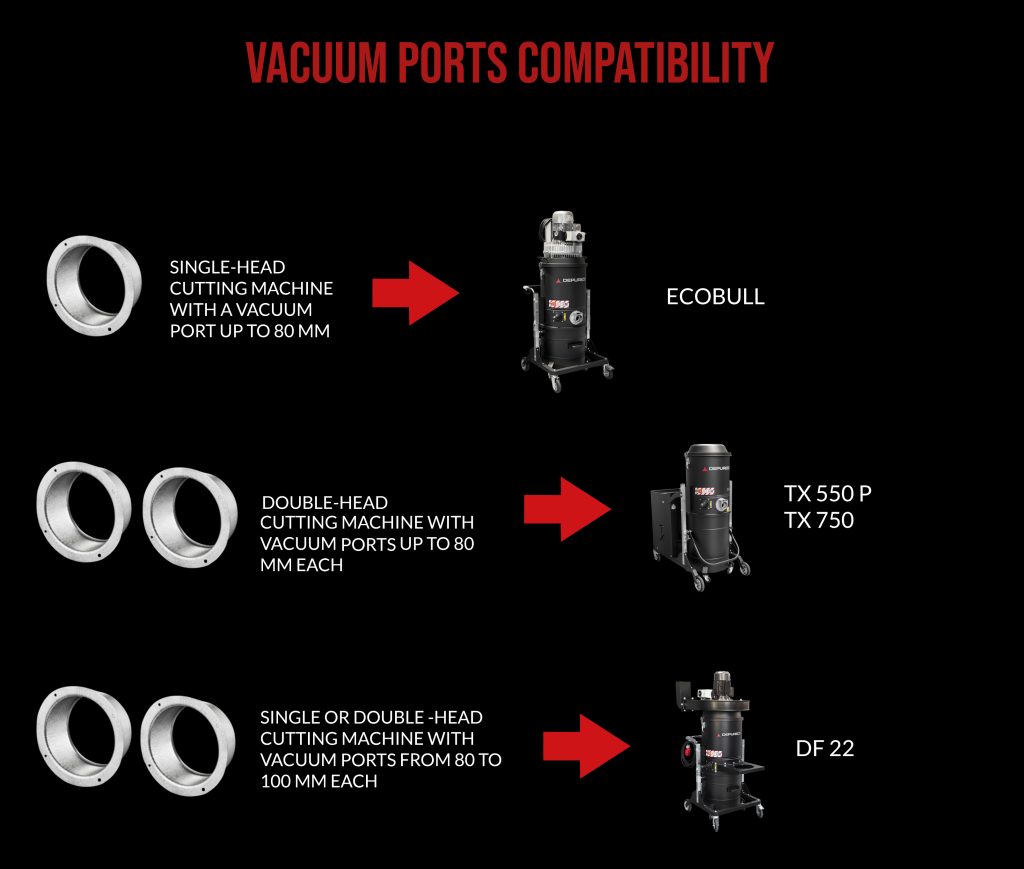

To collect the moderate amount of chips produced by a single-head cutting machine with a vacuum port up to 80 mm, we recommend our Ecobull industrial vacuum. With its 26-gallon container and power up to 4.8 HP, it’s the most convenient solution to prevent waste accumulation in the working area.

For efficient chip collection from double-head cutting machines with vacuum ports up to 80 mm each, the TX 500 P and TX 750 dust collectors are excellent choices. With power ratings up to 8.7 HP, these machines provide powerful suction capabilities. Their 26-gallon capacity allows for extended operation without frequent interruptions for emptying. Equipped with a side channel blower, both models ensure continuous performance, making them the ideal solutions for maintaining a clean and productive workspace.

The DF 22 dust collector is the perfect choice for handling significant amounts of chips in demanding applications. Its 3.5 HP electric fan provides powerful suction, while the 17-gallon capacity ensures long operation times without frequent emptying and delivering an efficient, continuous performance. Its connection allows it to work seamlessly with single or double-head machines with vacuum ports diameters ranging from 80 to 100 mm, making it the reliable solution for keeping your workspace clean and productive.

Within our range of vacuum solutions, you’ll find a variety of applications that can be directly connected to different types of cutting machinery. These vacuums not only enhance workplace safety by minimizing the accumulation of debris but also improve cutting precision and efficiency. With easy integration, reliable performance, and tailored solutions, our industrial vacuums are designed to meet the diverse needs of your operations

Contact us today to learn more about our industrial vacuums for aluminum cutting machines!