Every machining process creates its own kind of waste — sharp metal chips, fine dust, oil mist, or used coolant — and each requires a specific vacuum solution to stay safe, compliant, and efficient.

Every machining process produces specific types of debris — sharp metal chips, oily coolant, abrasive dust, or hazardous fumes. The right industrial vacuum system keeps your workspace clean and compliant, reduces unplanned downtime, and extends the life of your machines and fluids.

Whether you’re doing CNC turning, grinding, metal lamination, or molding, this guide will help you find the ideal vacuum solution for your process — from chip collection and coolant recovery to fume and dust extraction.

Scroll down to find the best match for your machining operation.

CNC turning continuously produces dry and wet metal chips, which can clog machine beds, reduce precision, and contaminate coolant. These by-products must be removed regularly to maintain quality and uptime.

The Depureco TX vacuum is designed for continuous-duty extraction, offering strong airflow and side channel turbine power to remove swarf and recover cutting fluids from turning operations.

Metal molding creates sharp fragments, metal powders, and oil-laden debris, which build up quickly around the mold area and reduce process efficiency. Proper cleanup is essential to avoid overheating and misalignment.

The Depureco M100 vacuum offers triple motor suction, robust filtration, and a steel tank, making it ideal for frequent, heavy-duty cleaning in molding environments with mixed contaminants.

Sanding and polishing operations release fine dust that can infiltrate electronics, coat surfaces, and reduce air quality. Without localized extraction, workers and machines are exposed to constant contamination.

The Depureco DF22 dust collector provides compact, mobile source capture with M-class or optional HEPA filters, built to handle even the finest airborne dust from finishing operations.

During metal drawing, wire, bar, or tube passes through dies, creating metal shavings, fine dust, and often oil contamination. This buildup can degrade die quality and pose slip hazards.

The Depureco TX vacuum handles solid-liquid mixtures with ease and is equipped with a side channel turbine for non-stop dust and chip removal — perfect for high-throughput drawing lines.

Lamination presses generate metallic powders, fumes, and mist, especially when heat or lubricants are involved. These contaminants reduce product consistency and increase machine wear.

Our Depureco Three-Phase industrial vacuums are built for high-volume, continuous use, with customizable filters and oversized tanks to manage long lamination cycles with minimal interruptions.

Tumbling processes create a mix of metal chips, dust, and abrasive media, which settle around vibratory bowls and finishing drums. Without regular cleaning, this can damage parts and increase downtime.

Choose between Depureco Single-Phase or Three-Phase vacuums based on your workload. Both include M/H-class filtration, antistatic options, and high collection capacity for effective tumbling waste cleanup.

Welding produces toxic fumes and ultrafine dust that threaten worker health and violate air quality standards. Standard room ventilation often isn’t enough for compliance.

Depureco welding fume extractors connect directly to MIG-MAG and TIG torches, capturing contaminants at the source. Multi-stage filtration, including HEPA, ensures safe, localized fume control.

Grinding operations generate a hazardous mix of abrasive metal dust and dirty coolant, which can clog machines, reduce part quality, and pose inhalation risks.

Depureco’s sump vacuums filter and recycle oil while removing fine dust and metal shavings, helping grinders stay clean, cool, and fully operational with minimal downtime.

Cold forming involves high-pressure shaping of metals, creating large volumes of wet and dry chips that must be removed continuously to prevent workpiece damage or machine failure.

The Depureco M100 JetClean vacuum is built for high-load collection, with three powerful motors, a 26-gallon tank, and semi-automatic filter cleaning — ideal for chip-heavy forming processes.

From CNC turning to grinding and metal lamination, each machining process creates unique cleanup challenges — and the wrong vacuum system can lead to clogs, coolant contamination, and costly downtime.

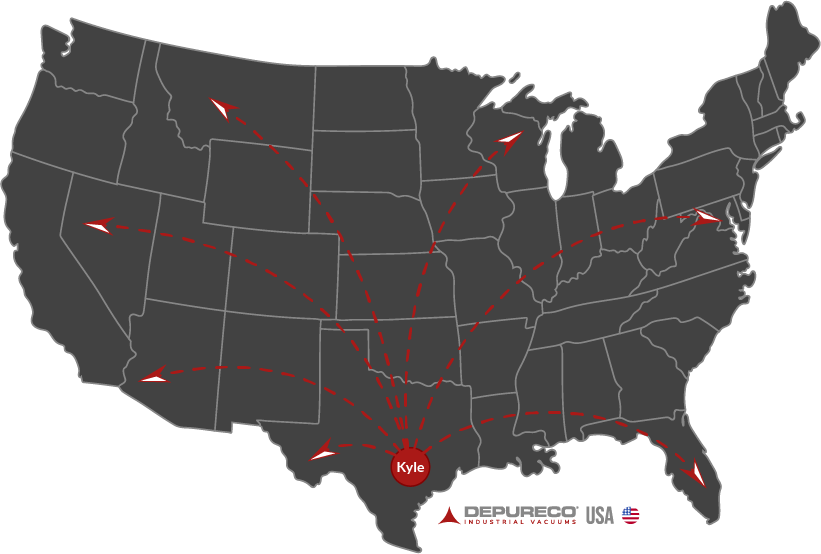

Depureco’s industrial vacuum solutions are built for the demands of metalworking environments. Whether you need to recover cutting oil, separate wet chips, extract fine dust, or clean CNC sumps, our systems deliver.

We will give you all the required information