OIL AND SWARF

Stop Wasting Coolant.

Reclaim 95% of fluids, filter chips instantly, and get back to work in under 10 minutes. No scooping. No mess. No downtime.

Perfect for prototype labs, job-shops and single-spindle CNCs

The sweet spot for mid-size VMCs, horizontal lathes and dual-pallet machining cells.

High-capacity flow-inversion for large HMCs, gantry mills and central coolant pits.

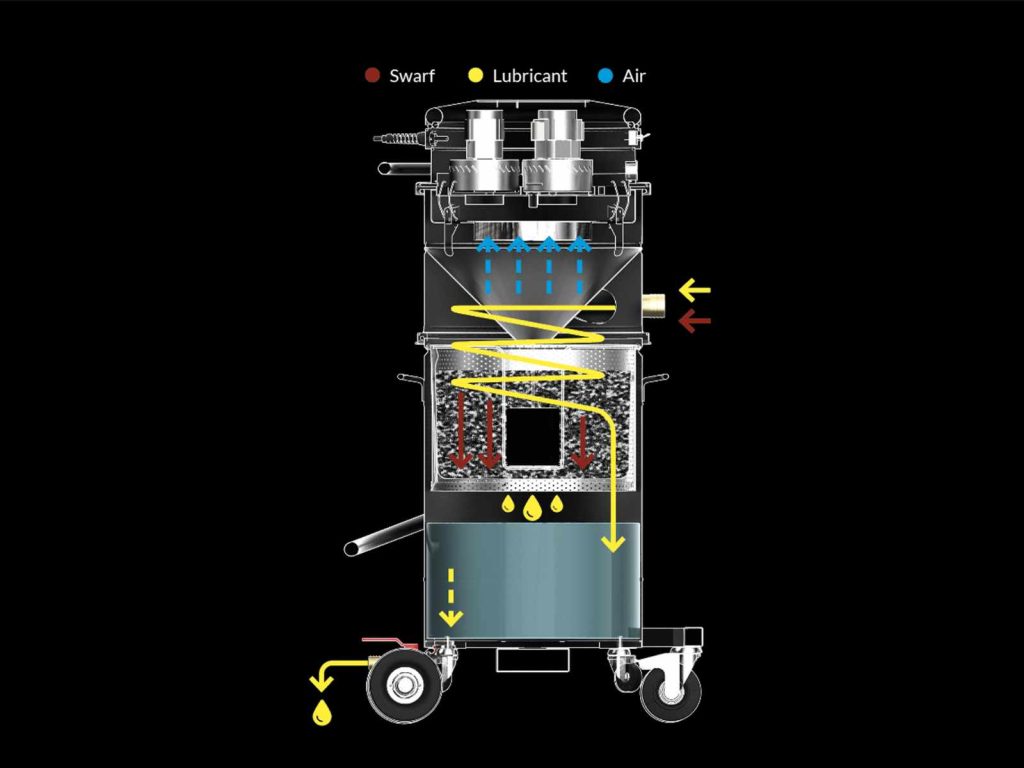

A stainless-mesh chip basket teamed with a 150-micron PPL filter keeps metal shavings out of the fluid stream. Chips drop dry into the basket for premium scrap resale, while the filtered coolant drains into an epoxy-coated steel tank ready for immediate reuse or drum transfer.

Result: Clean coolant back in the machine, zero pump damage, zero filter consumables.

Every gallon of coolant you reclaim is a gallon you don’t buy—or pay to haul away. By removing solids, a Depureco sump vacuum cuts coolant disposal fees, eliminates tramp-oil fines from waste haulers and converts dry chips into high-value scrap metal. Shops typically save $9,500+ per CNC per year in fluid, labour and scrap uplift.

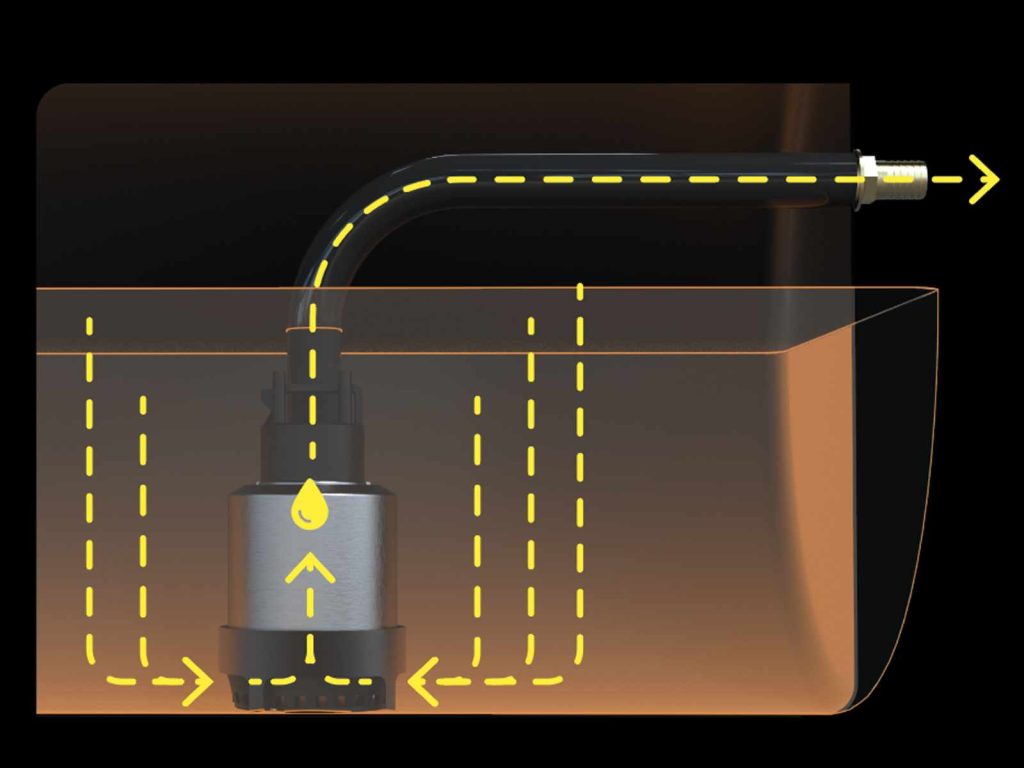

A heavy-duty submersible discharge pump lets you vacuum and refill at the same time: suction pulls chips and dirty coolant into the tank while the pump returns filtered fluid to the machine at up to 120 GPM (2 gal s⁻¹). Continuous operation means no waiting for the tank to fill, no secondary transfer step, and no downtime between shifts.

Grounded hoses, IP55 motors and optional ATEX Zone 22 certification eliminate ignition sources; float-switch prevents messy over-fills—meets OSHA 1910.22 and NFPA 652/484 housekeeping rules.

Reverse-pulse blast clears the 150 µm basket in <10 s—no tool, no downtime, constant airflow.

Side-channel blowers run below conversational level—ideal for lights-out machining cells and night shifts.

500 × 600 mm chassis fits between CNC rows; heavy-duty casters glide over chip piles; fork-pocket frame on RAM series for one-forklift relocation.

Hinged lid and quick-release basket let operators rinse filters in under two minutes—no loose fasteners to drop in the tank.

Side-channel electric blowers draw 30 % less energy per CFM than comparable Venturi air vacs—lower utility cost, smaller compressor.

Snap-on cyclones, endless-bag drums, and tilting 580 L bins protect filters and multiply chip capacity for high-volume production.

Tell us about your chips, coolant volume, and floor space—our engineers will size the right vacuum, include accessory recommendations, and send a detailed quote (with freight and lead-time) within one business day. No spam, no obligation—just the right solution you need to keep your spindles turning.